The bathhouse is a building with difficult climatic conditions. Temperature and humidity are constantly increased here, walls and floors interact with water. The saunas have two rooms - a steam room and a relaxation room. The temperatures in them differ, therefore the thermal insulation will be different. For a comfortable acceptance of water procedures, it is necessary to make the floor insulation, taking into account the peculiarities of the structure.

The need for insulation

Despite the high temperatures in the bath, the floor remains cold without high-quality insulation. Without good thermal insulation, it will take more time to heat the room, and fuel costs will also increase. The temperature will drop faster.

The sudden temperature difference between the top and the floor can have a negative impact on health. This factor is especially dangerous for children and people with weakened immunity.

It is imperative to insulate the floor in the bath. For this, different techniques and materials are used, which are selected taking into account the individual characteristics of the building.

Types of heaters

It is not difficult to make insulation with your own hands. It is important to choose the right material and installation method. The following heat insulators are placed on the floor in the bath:

- Polystyrene. Inexpensive material with low weight and good rigidity. It is convenient to cut it with an ordinary knife. Suitable for wood and concrete floors.

- Styrofoam. Traditional insulation with low thermal conductivity, which is suitable for any construction.

- Minvata. Suitable for wood flooring. Has good thermal insulation properties. The disadvantages include moisture absorption, therefore, waterproofing is necessary.

- Expanded clay. Placed on concrete. It can be used as a base and as a filler for filling the first layer. The high cost is distinguished from the minuses.

- Perlite. Used on concrete. After creating the mixture according to the instructions, it is an expanded solution that is poured between the base and the top screed. Has high strength.

- Penoplex. Differs in moisture resistance, strength and resistance to mechanical stress. It is a kind of polystyrene. Insulation of the floor in the bath with penoplex can be done on wood and concrete.

- Vermiculite. It is rarely used due to its high price. Keeps warm well, resistant to open fire.

The listed heat insulators have been used for a long time and have been tested by time. But there are also more modern methods of floor insulation that are applicable to concrete. These include boiler house slag, which is a good alternative to expanded clay. From folk methods, thermal insulation with glass or plastic bottles can be noted. The floor covering is laid on top of them.

You can also install a warm electric floor in the bath.

Requirements for the insulation of different rooms

In the rest room and dressing room, the requirements for thermal insulation are not so strict, since the humidity and temperature are lower.

Necessary materials

The choice of tools for insulation is individual. An approximate list of materials and equipment for insulating a wooden floor:

- Roofing material, glassine, sheet polystyrene. Of these, waterproofing or vapor barrier is performed.

- The insulation itself. It is selected based on the chosen styling technique and the owner's financial capabilities.

- Cement, sand, water. Necessary for the preparation of solutions if they will be used as a heat insulator.

To insulate a concrete floor, you need:

- Coating waterproofing and roll. It can be bituminous mastic, roofing material.

- Insulation.

- Cement, water, sand.

The calculation of the amount of materials depends on the individual characteristics of the room. From the tools you will need a ruler, knife, square, level, pencil, puncher, dowels. First, you need to carry out calculations and create a laying scheme. It is necessary to provide a place for water drainage and drainage.

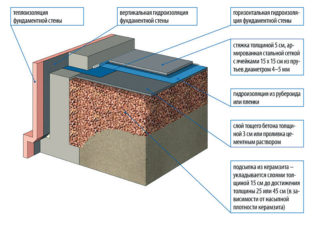

Insulation with a screed on the ground of a concrete floor

This insulation method has good efficiency and reliability. A multi-layer structure will be considered, which can be changed depending on the climatic conditions of residence. A layer of dry concrete (about 5 cm), foam concrete (10 cm), expanded clay (15 cm), sand cushion (15 cm) is laid. The thickness can also be changed.

Algorithm of work on thermal insulation of a sauna:

- Markup. The height of the coating should be at the level of the subfloor, which must be taken into account when choosing the number of layers. These marks for each layer should be applied to the walls.

- Leveling the ground. Can be done with a shovel "by eye" without using a building level.

- Laying a layer of dry sand on earth or clay. It is used to damp vertical loads when soil heaving. Do not pour water onto the sand to compact it.

- Laying expanded clay. It can be replaced with porous waste or slag.

- Pouring expanded clay with concrete. To obtain a porous structure, special drawdowns are added. You can buy them at a hardware store. The concrete must stand for 2-3 days to dry completely, and only after that work can be continued.

- Laying the topcoat or creating a cement-sand screed. The second option allows you to increase the strength and reliability of the structure. It is recommended to make a screed with dry concrete on a reinforced mesh.

The topcoat - tiles or other material - can be placed on dry concrete on the second day.

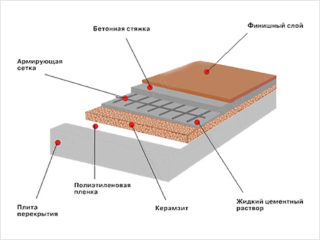

Insulation on the floor slab

With this installation, a layer of thermal insulation is laid over the floor slab on the foundation. It must first be covered with a layer of waterproofing. A reinforced mesh is applied on top, which is poured with a cement-sand screed. When the concrete is dry, the final coat can be laid.

Expanded clay can act as thermal insulation. In this case, the following steps are taken to insulate the floors in the bath:

- A thick layer of polyethylene film is placed on the rough concrete floor. It must also be brought to the walls.

- Finishing level marking, placing beacons on it.

- Laying expanded clay. It can be filled directly from the bags or by mixing two different fractions. Both methods provide good thermal insulation.

- The embankment is leveled and reinforced with a surface layer of cement.

- If necessary, a reinforcing mesh is placed.

- Filling of expanded clay layer. The screed height is 30-40 mm.

- Removing air bubbles with a special roller.

When the floor is dry, you can lay the final coat in the washroom.

Features of wood floor insulation

Thermal insulation technology for wood floors is similar to working with concrete. But you need to take into account a number of nuances in order to properly insulate the floor in a bath under a wooden floor:

- Insulation. The best option for the floor is polystyrene foam in the form of mats. It does not allow moisture to pass through, so no waterproofing layer is required.

- Preparing a rough plank floor.It can be made from low-grade boards that will be attached to the joists.

- Waterproofing. The membrane is designed to reduce the effects of steam and water on beams and subfloors. When decking, it is important to close all joints and make an allowance on the wall.

- Final sealing of the holes with polyurethane foam, cleaning the floor. It is recommended to lay the finished floor at a distance of 4 cm from the lower level. This will ensure good ventilation and quick drying.

Closed cellular structures should be taken into the steam room and sink. Mineral wool and other porous materials should be laid in the rest room and dressing room.

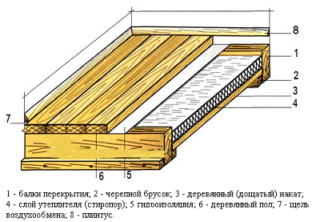

Thermal insulation on wooden logs

The stacking algorithm is as follows:

- Logs are made of wood with dimensions of 50 × 180 mm. They should be laid on a foundation strip or piles. The distance between the lags should be equal to the width of the heat insulator.

- At the bottom of each lag, cranial bars should be fixed. Subsequently, a subfloor made of boards is laid on them.

- Laying waterproofing. Polyethylene or PVC can be used as a film.

- Laying thermal insulation into the resulting cells.

- Closing the insulator and lag with a layer of waterproofing. All joints should be glued with construction tape or special tapes.

- Laying floorboards.

When working, it is important to lay the materials so that there are no holes. Water can get into them, due to which the thermal insulation properties deteriorate and mold forms.