To create comfortable conditions in a closed garage space, it is recommended to insulate the doors. This will also preserve the presentation of the car and its performance.

- For what types of garage doors is insulation done?

- What to use as insulation

- Styrofoam

- Mineral wool

- Polyurethane foam

- Penoplex

- Stages of insulating garage doors from the inside with your own hands

- Surface preparation

- Manufacturing of lathing

- Gate insulation

- Facing the inner surface of the doors

- Additional measures

For what types of garage doors is insulation done?

Most often, swing structures are installed in garages, which must always be insulated. They are completely metal, and steel has a very low thermal insulation rate. There are practically no obstacles between the street chill and the inside of the garage.

Sectional and overhead doors are very popular. They are mainly made from sandwich panels in the factory. A layer of expanded polystyrene insulation is applied to the steel outer shell. The high thermal insulation characteristics of this material make additional insulation of the garage door unnecessary.

It is impossible to insulate roller shutters. This is due to their design features. The anti-vandal and thermal insulation properties of this structure are so low that they can hardly be called a suitable garage door.

What to use as insulation

To insulate garage doors from the inside with your own hands, you can choose insulation from a large number of proposals from manufacturers.

Styrofoam

This is a generic name for synthetic foams based on polymers. Polystyrene foam is the most famous type. In finished form, this is a set of white balls connected into a monolith. It is often used by craftsmen who make insulated garage doors. The material is lightweight, minimally hygroscopic, fireproof and durable.

Another material often used as a heat insulator is polyurethane foam foamed plastics. They are of two types. The first is ordinary foam rubber, and the second is polyurethane foam. The last product is used for insulation. When applied to the surface, all free cavities are filled.

Mineral wool

The material actively used in construction is divided into 3 subgroups: stone wool, slag wool, glass wool. The first insulation is not very often used for gates due to its hygroscopicity. Glass wool contains many very small glass particles. Its thermal conductivity index ranges from 0.03 to 0.05 W / m * K. It is recommended to observe special safety measures when working with this material.

For the manufacture of slag wool, metallurgical residues (slags) are used. It has almost the same low thermal conductivity as the previous material. However, it is not worthwhile to carry out insulation of the garage door from the inside with your own hands - it does not tolerate proximity to metal.

Polyurethane foam

It is applied to the surface by spraying. The thermal conductivity is very low. The material is non-toxic, but flammable. Despite all the positive qualities, it is not used very often, since it cannot be applied without a special installation.

Penoplex

Able to solve several problems at the same time:

- provide high-quality thermal protection;

- save money on heating;

- create a comfortable microclimate in the room.

Strong structure and low weight make this material easy to install.

Stages of insulating garage doors from the inside with your own hands

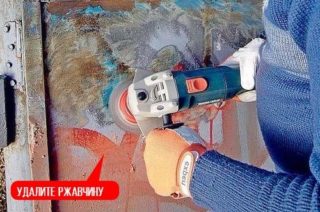

Surface preparation

Do-it-yourself garage door insulation begins with an inspection for paint peeling and rust. The detected violations of the integrity of the surface are eliminated. Next, processing is carried out with fine-grained sandpaper.

Manufacturing of lathing

Bars are used as a material, which are sawn in accordance with the dimensions of the gate. At the same time, they try to stack whole pieces as much as possible. The bolts and all available holes are framed. To fasten the bars, self-tapping screws are used, the holes for which are made at a distance of no more than 25 cm. The length of the fasteners is selected so that their tip does not go through the bar.

Gate insulation

The stage begins with marking the insulation. It is done in such a way that the workpiece fits snugly into the space between the bars, leaving no gaps. After that, the elements are cut. This usually requires outside help.

To keep the insulation securely in its "nests", its surface is coated with silicate glue. You can also extrude the polyurethane foam sealant. Its plus is that it fills in all the free spaces, if any, during installation.

Facing the inner surface of the doors

From a practical and aesthetic point of view, the stage of sheathing of the inner surface of insulated gates is important from a practical and aesthetic point of view. There are several popular options:

- Sheathing rail car. This inexpensive, environmentally friendly material looks quite presentable. She is not afraid of temperature extremes and mechanical stress. Self-tapping screws are used to fasten the lining to the frame.

- Use of PVC panels. Their surface does not require any special maintenance. The installation process is simple and fast. The service life is long, but the panels do not withstand mechanical stress.

- Moisture-resistant plywood has high technical and environmental characteristics. She has one drawback - not everyone has an acceptable price.

- OSB panels. With the help of this inexpensive material, it is possible to reliably and aesthetically sheathe the entrance to the garage.

The choice of material depends on the personal preferences of the owner and his material capabilities.

Additional measures

To get the desired result, you need to insulate the gaps. No matter how conscientiously the work is done, it is still impossible to avoid the occurrence of cracks. Their presence allows cold air to enter the garage.

You can get rid of gaps using thresholds and inserts. Vinyl inserts are glued along the edges of the sash. As a rule, paint is used as an adhesive. Before installing the threshold, dust and dirt are removed from the surfaces. For fixing, special glue is used.