Control over the operation of the heating system can be carried out in several ways. For this, various types of equipment are installed: mixing units, automation for timely replenishment, security groups. But regardless of the type, each of them must have pressure and temperature sensors in the heating system. Each owner of an autonomous or centralized network should be aware of the functional features and types of these devices.

Purpose of measuring devices

What does any type of heating have in common? This is a periodic change in the temperature of the coolant and, as a consequence, in its pressure. To monitor the indicators of the degree of expansion of water, pressure sensors in the heating system are required. With their help, you can observe the current data and in case of their deviation from the norm, take appropriate measures.

Temperature sensors for heating have a wider range of applications. In addition to visual displaying the degree of heating of the coolant in certain sections of the system, they can record air temperature data in a room or outdoors. Together, the two types of devices should form an effective tool for tracking, and in some cases - automatic stabilization of the parameters of the heating system.

How to choose the right water pressure sensor in the heating system or a thermometer? The main criteria are the parameters of the system. Based on this, the following requirements are imposed on measuring instruments:

- Measuring range... Not only the accuracy depends on this, but also the relevance of the information. So, a temperature sensor in a heating system with an incorrectly selected upper limit will show biased data or fail;

- Connection method... If you need to know the level of heating of the coolant with high accuracy, you should choose immersion models of thermometers. A classic pressure sensor for heating can only be mounted directly into the heating main of a house, a boiler or radiators;

- Measurement method... The method of taking readings affects the inertness of the device - the delay in displaying the actual data. It also determines the appearance and visualization of parameters - arrow or digital.

In an open system, the pressure parameter is not important, since it is almost always equal to the atmospheric one. However, heating temperature sensors are installed in any scheme - gravitational, forced circulation or when connected to a central network.

For ease of monitoring the system readings, you can purchase a device that combines a pressure and temperature sensor. Despite the relatively high cost, it is much more convenient to take current data on the state of heating with its help.

Temperature sensors for heating

Even at the heating design stage, it is necessary to choose heat sensors for heating - types and their characteristics. First of all, they differ in the place of installation - directly into the system or for remote control of other temperature indicators. The latter are used in conjunction with room thermostats.

Immersion sensors

Designed for taking readings about water heating in pipes. Their installation is carried out in certain areas of the system.Some models of solid fuel boilers do not have temperature sensors for heating. Therefore, it is imperative to eliminate this.

The choice of model depends on the way the readings are taken.

- Bimetallic... The design of these temperature sensors for the heating system consists of a dial gauge and two metal plates made of different metals. When heated, one of them begins to deform, creating pressure on the indicator needle. This technique is characterized by high accuracy of readings, but has one drawback - relatively high inertness. Average price - from 600 to 900 rubles;

- Alcohol... Compared with the above-described view, the display inertness of the water heating value is practically absent. The principle of operation is in many ways similar to a conventional thermometer - an alcohol-containing composition is placed in a sealed flask, which expands when heated. The marks on the bulb of this type of heating temperature sensors indicate the current value of water heating. The design is simple, but inconvenient for observing the readings. Cost - from 1900 rubles.

To install these heat sensors for heating, you first need to read the instructions from the manufacturer. It contains the installation dimensions for connection to the nozzle, temperature limits and recommendations for use.

When choosing immersion thermometers, the length of the well must be taken into account. It can be from 120 to 160 mm.

Remote sensors

They are located outside the heating system, but can be connected to a boiler or programmer to adjust parameters. Recently, wireless models have become popular, which transmit information using auxiliary electronics. This makes it possible to install them almost anywhere - in a separate room or on the street.

Defining characteristics of heating temperature control sensors:

- Signal range;

- Availability of self-contained batteries - batteries;

- Measurement error.

For simple circuits, you can install wired temperature sensors of the heating system. The signal is transmitted from the thermometer to the control device (or boiler) through wires. In this case, the likelihood of error or incorrect data is much less than with wireless models.

For better communication of remote thermometers with the rest of the equipment, it is best to choose models of the same brand (manufacturer).

Pressure sensors for heating

Pressure sensors in the heating system must be provided in a forced circulation circuit. In fact, they represent the degree of expansion of the heating medium as a result of heating. Therefore, experts advise the installation of pressure sensors in the heating system together with thermometers.

The main indicator for pressure gauges is the pressure limit values. In an autonomous network of a private house or apartment, the normal indicator is from 1.5 to 2.5 MPa. Accordingly, the maximum allowable value for the water pressure sensor in the heating system must be at least this data. In practice, it is recommended to install models with an upper limit of 6 MPa. An important factor is the mechanism by which the pressure gauge displays the readings.

Spring sensors

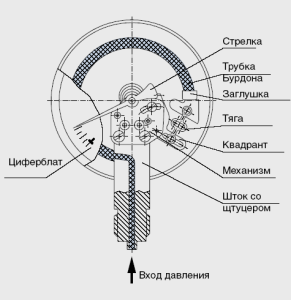

A special tube acts as a sensitive element at the pressure sensor for heating. It can have a round or oval cross-section. Under the influence of the pressure of the coolant, it is displaced, as a result of which the arrow on the dial moves.

The advantage of devices of this type is reliability and affordable cost. The operating time depends on the frequency of exposure to the sensing element, as well as exceeding the maximum allowable pressure. In addition, the following requirements are imposed on spring pressure sensors in the heating system:

- Deviations from the error value are inadmissible. If, in the absence of pressure, the arrow is not at the zero mark, the device cannot be exported;

- Accuracy class for household pressure gauges must be at least 2.5;

- During mechanical impact on the device, the sensing element of the pressure sensor may move. Then changes in the heating system will not be recorded, or the error will exceed the permissible limits. To avoid this, a check must be carried out before the start of the heating season.

Installation of spring water pressure sensors in the heating system is simple. To do this, you need to install it on the threaded connection of the inlet pipe. You cannot use the FUM tape - only a rewind designed for critical pressure and temperature values.

Diaphragm sensor models can be an alternative to spring-loaded pressure gauges. They give more accurate readings, but are prone to frequent breakage due to the sensing element.

Electrical contact sensors

They are an improved model of a spring-loaded pressure sensor. They are used for heating with automatic regulation of indicators. In addition to the main arrow, there are 2 additional arrows in the manometer. They are set to the maximum and minimum pressure values. When one of them reaches the main arrow, the electrical contact closes and a corresponding signal is sent to the control element. Such devices are used in large stand-alone systems. For autonomous heating, their installation is impractical.

It must be remembered that each pressure and temperature sensor in the heating system must display actual values. Therefore, you should first make an accurate calculation of the entire system, and then, based on the obtained indicators, select the optimal model of the device.

In the video, you can see the use of a temperature sensor in the design of a solar collector - one of the types of heating: