Any type of heating should be a well-coordinated system, the operation of which largely depends on correctly selected components. First of all, attention is paid to the main nodes of the circuit - the boiler and radiators. But there is a certain kind of components, without which functioning is impossible in principle. These include components for heating systems: radiators, batteries, pipes, houses and apartments. What are they and what functions should they perform?

Appointment of components for heating

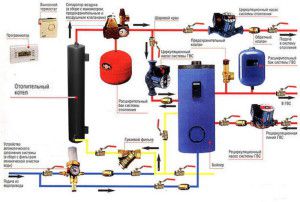

The principle of operation of the heating system is known to everyone. In the stand-alone version, the boiler is connected to the distribution main (pipes). The heated water begins to circulate and through the radiators gives off most of the thermal energy to the premises.

Correctly selected components for water heating are necessary for the timely adjustment of the system parameters - the heating level of the coolant, its distribution along the branched line. In addition, installation is impossible without them. In particular, polypropylene heating components (fittings, plugs, distributors) are used to create a pipeline.

What should be considered when choosing components for heating?

- Design parameters - thermal conditions and heat carrier pressure values (for systems with forced circulation);

- After installation, accessories for heating boilers or batteries should not affect the performance and characteristics of the system. First of all, this relates to the throughput of the pipeline and the value of heat output for radiators;

- Cost. This characteristic often directly affects the quality of components for heating aluminum radiators and steel analogs. Experts recommend purchasing all components from one manufacturer whenever possible.

These are general requirements that do not in any way reveal the functional and design features of components for heating systems. Therefore, you need to consider each group separately.

Before installation, you need to know the technical parameters of the heating elements. This can be done by reading the product passport, on the manufacturer's website or directly from a consultant before purchasing.

Shut-off and control valves for heating

The proper functioning of heating is impossible without the installation of taps, valves and similar elements. They are necessary to partially or completely stop the flow of coolant in a specific section of the pipeline. These components for heating a private house are collectively called shut-off valves.

Taps and valves for pipes and radiators

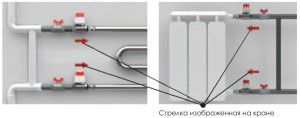

Structurally, they are a mechanism in which the possibility of changing the useful section of the line up to the complete blocking of water is provided.

They are divided into 2 types - ball and needle. The former are used for operational water shut-off. The ball installed in the valve has a through hole. When its axis coincides with the direction of movement of the coolant, water flows unhindered along the line. When shifting, the actual throughput of the system decreases.The main advantage that these components for heating systems have is the ability to quickly shut off the water. To do this, it is sufficient to turn the lever 90 °. If you need a smooth adjustment, you should install needle-type taps and gate valves.

When choosing and installing these components for hot water heating, the following factors should be taken into account:

- The maximum throughput must correspond to the same parameter of the pipe in this section of the system;

- Operating values of temperature and pressure;

- Their installation is necessarily carried out at the outlet of the boiler, before connecting each radiator, in mixing feed units;

- Reliability. Components for solid fuel heating boilers made of stainless steel have proven themselves best. But given their relatively high cost, brass models are most often chosen.

The installation of shut-off valves should be carried out according to a previously drawn up scheme. It is recommended to pre-calculate the parameters of each valve or gate valve.

During the first start-up of the system before the winter season, it is necessary to check the operability of all components for heating, and in particular - the piping of aluminum radiators.

Adjustment fittings for batteries

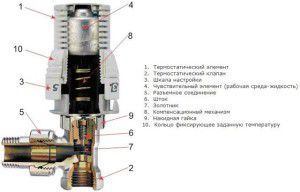

It includes such type of components for heating aluminum radiators as thermostats. They perform the same function as shut-off valves, but with additional features.

The thermostat must be mounted on the inlet of each radiator. The adjustable head is used to set the optimum temperature. If a deviation of the heating agent heating level is recorded in the sensitive element of this component for heating a private house, it will reduce (increase) its flow into the radiator.

The main characteristics of thermostats are:

- The degree of adjustment and the operating error of the sensing element;

- Possibility of installing a servo drive to regulate the coolant flow in automatic mode;

- Connection of a separate thermal head to create a unified heating control system on different sections of the line.

You can do the installation of accessories for heating radiators yourself. It is necessary that the mounting diameter of the thermostat coincides with the same parameter of the radiator inlet pipe.

To eliminate air plugs, you need to install a Mayevsky valve - a manual drain valve as components for a heating radiator.

Heating system safety

Another type of polypropylene and steel heating accessories are devices that ensure the safety of the entire system. During heating operation, the temperature of the coolant or its pressure may go beyond the normal range. To stabilize these indicators, a special type of components for heating systems should be installed.

Heating safety group

It consists of three elements - an air vent, a drain valve and a pressure gauge. It is installed at the point in the system where the values of temperature and thermal expansion of water will be maximum - right after the boiler.

The air vent removes the steam generated by overheating of the water from the line. In this way, air pockets in radiators and pipes can be prevented. The drain valve is a mandatory accessory for closed type heating with forced circulation. During the overheating of the coolant, it expands, thereby creating excess pressure. The "excess" volume of water comes out through the drain valve branch pipe. But at the same time, it is necessary to provide for an additional component for heating boilers - an automatic feed unit for the system.

The defining parameters for a security group are:

- Mounting pipe diameter - usually ½ ”;

- Possibility of adjusting the maximum pressure value for activating the air vent and drain valve;

- To install these polypropylene heating accessories, metal / plastic adapters must be purchased.

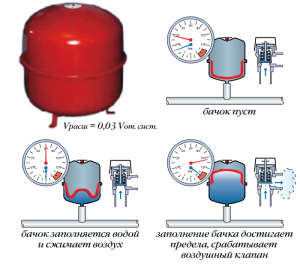

But what else needs to be foreseen in the heating system for its complete safety? In schemes with forced circulation, a membrane-type expansion tank must be installed.

The outlet of the drain valve is best connected to a sewer system. This way you can avoid getting the coolant on the floor.

Heating expansion tank

It is designed to stabilize the pressure at its small deviations. Also applies to heating components in a private house, which are designed to prevent emergencies.

Before purchasing an expansion tank, you must first calculate its optimal volume. The possibility of replacing the elastic membrane is important, which may lose its properties over time. For this, it is best to purchase models with a flange-mounted diaphragm.

In addition to the above, the main components of the heating system include measuring instruments - manometers and thermometers. They are installed at points in the pipeline where it is necessary to visually control the parameters of the temperature and pressure values.

These are the main types of components for heating systems: radiators, batteries, pipes, houses and apartments. Their type and list depends on the parameters of the heating system. The constituent elements of pipelines (connecting, corner, branching) are selected based on the material of manufacture. For stand-alone systems, it is preferable to use plastic, since they are easy to install and do not require special skills and complex tools.

More details about the features of the assembly of plastic pipelines are described in the video: