The peculiarity of brick ovens is manifested in the susceptibility of their surfaces to constant exposure to critical temperatures. Therefore, plaster for stoves must have an increased fire resistance. This requirement must be taken into account when preparing the components for clay mortar on your own, especially when choosing the right proportion.

Types of plasters and their composition

The mixtures by means of which it is possible to plaster the stove are divided into two classes: simple and complex. The former include solutions that include only two components: ordinary clay and sifted sand. Special types of solutions are considered complex, which contain more than 2 components, which include:

- asbestos used as a reinforcing component;

- its substitutes, represented by hemp, finely chopped straw or microfiber;

- gypsum, often used in thermal plaster instead of cement.

Particularly noteworthy is gypsum, which is part of some plasters and performs the function of a bonding agent. It is used together with lime, which gives the solution additional strength and the ability to dry quickly.

The specificity of this substance is that it quickly solidifies - the composition is set within 10-15 minutes after mixing. Before plastering brick stoves, it should be borne in mind that you need to mix the gypsum composition in small fractions. Otherwise, the finished mixture will harden after some time and become unusable.

Clay for the stated purposes is chosen oily, since the strength of its adhesion to walls (adhesion) and the ability to withstand high temperatures depend on this property. Some of the components require mandatory preparation and cleaning before preparing the mixture. Its need is due to the following reasons:

- Sand usually contains a lot of all kinds of impurities, which are removed by sifting it through a fine sieve.

- The clay is rubbed through a fine-mesh metal mesh, after which it becomes like a powder. In this form, it is more convenient to remove the roots of various plants and small stones from it.

At very high temperatures, asbestos begins to release harmful substances. Therefore, it is increasingly being replaced by special fiber reinforcing additives.

Criterias of choice

A good master tries to plaster the stove in the house in such a way that its coating does not crack over time and lasts as long as possible without crumbling. For this, it is important to adhere to certain criteria. They are very simple and mainly concern the correct choice of the working staff. It must meet the following requirements:

- be environmentally friendly and do not contain harmful impurities;

- withstand critical temperatures without cracking or chipping from surface heating;

- have good thermal insulation properties.

It is not allowed to add drying oil or oil paints in any form to plastering compounds. When a Russian stove is melted, they melt, and the chemical compounds contained in them decompose.

Preparatory work

Preparatory measures are reduced to the choice of the components of the solution that is optimal for the given conditions and to the specific type of oven surface. Particular attention is paid to the ratio of these components and the following important points:

- with very oily clay, more sandy component is added to the mixture;

- she must be soaked before that;

- after all the water is absorbed, add a little more until the liquid covers the clay with a top by 100-150 mm.

At the end of this procedure, the mixture of clay and water is mixed until a very thick sour cream, in the prepared form, has good plasticity.

Self-cooking

When making plaster for a brick oven with your own hands, it is important to provide in advance so that the solution does not crack, does not flake off and looks quite aesthetically pleasing. To do this, you will need to do the following operations:

- After removing dirt and remnants of the dismantled coating, the masonry joints should be cleared 5-10 mm in depth.

- It is necessary to drive nails into the seams in increments of about 15 cm so that they protrude about a quarter of the length above the brickwork.

- Treat brickwork with a primer.

- Wait until the soil is completely dry, after which the stove should be melted.

In the pause, you will need to prepare the plaster mixture according to the instructions. Cooking at a time should be such an amount that can be consumed until it begins to dry out. Further procedure:

- Moisten the brick surface using a wide brush.

- Attach pre-prepared fittings to it.

- Using a trowel, apply the first layer 0.5 cm thick, fixing the mesh (it is allowed to fix it with nails at the seams).

- After it has hardened, a second layer is applied with an estimated thickness of about 1 cm.

- As soon as it hardens slightly, you will need to moisten the plane with water.

- Grout dry surfaces with sandpaper or a float.

It is obligatory to check the coating for the presence of obvious chips. If they are present, it is necessary to widen the cracks, and then moisten them with water and fill with the solution again. After it dries, you will need to wipe the surfaces again.

During work, experts advise adhering to the following recommendations:

- it is necessary to process the walls of the furnace only in the direction from top to bottom;

- the first of the two layers is made more liquid, and the second thicker;

- on the hammered nails, like on beacons, it is convenient to equalize the layer thickness and distribute the solution evenly over the entire surface. If necessary, it is allowed to putty it over the resulting coating.

To check the quality of the plastered surface, a level is used to check that the deviation in the thickness of the layer along the entire surface of the furnace does not exceed 1-2 mm.

To make it look more attractive outwardly, and to comply with the current standards in terms of the strength of the plaster coating, one of the following finishing methods is chosen:

- The surface is covered with chalk rubbed in lime milk.

- It is processed with milk of lime mixed with salt.

In the second case, the proportion is adhered to - one bucket per 100 grams of salt.

Ready mixes

The building materials market is filled with various types of refractory products that allow you to plaster stoves yourself. The most popular, well-deserved recognition, are heat-resistant compounds "Refractory", "Terracotta", "Pechnik".

Refractory mixture produced in three modifications:

- smooth plaster;

- simulated mixture;

- composition for tiled surfaces.

When using a modeled variety, it is possible to obtain a textured surface on which any drawing can be easily applied.The smooth compound is ideal for painting most ovens.

"Terracotta" is another dry mixture, which includes clay and fine chamotte sand with refractory additives. The mortar is intended for processing surfaces made of ceramic and fireclay bricks and can withstand heating temperatures up to 200 ºC.

The composition called "Pechnik" includes lime and sand, as well as gypsum, cement, asbestos and clay.

Decorative cladding for fireplaces

A fireplace is a decoration of any country house.. The following natural materials are used for its decorative facing:

- marble and granite in the form of stones or tiles;

- onyx or serpentine;

- sandstone and white limestone.

Even taking into account that granite has good resistance to sudden changes in temperature, it is not recommended to use it for cladding interior surfaces.

Marble is the most suitable material for decorating fireplace walls in the country or in a country house. It adapts well to extreme temperature fluctuations and is ideal for indoor and outdoor use.

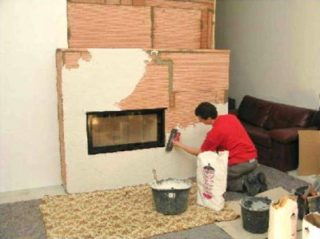

Cladding procedure

The fireplace is finished with the use of a reinforcing mesh; when working with tiles, the installation technology is slightly modified. It is carried out in the following order:

- A mesh is attached to the surface, after which it is carefully leveled. For these purposes, special adhesives are used.

- The mesh is fixed by means of nails driven directly into the seams.

- Decorative tiles are mounted on a leveled and well-dried surface.

- The material selected for the cladding is laid from bottom to top, the glue is applied using a notched trowel.

During installation, the tiles are manually pressed against the surface of the fireplace, and then leveled with a light tap of a rubber mallet. Plastic crosses are placed between adjacent tiles to maintain even seams. At the end of the work, they are removed.

A lot of salt must be added to the solution

Yes, professionalism is felt, but asbestos does not emit anything at high temperatures, especially since nothing heats up in the oven above 650 degrees, which is not high for him. its dust ie, small particles of it.