A high-quality heating system is an indispensable factor for ensuring a comfortable life for people in an apartment building. For energy efficiency to be at a high level, it is necessary to comply with the requirements for the installation and placement of radiators. There are established norms for the location of heating devices, following which you can ensure the optimal temperature in the house and reduce heating costs. Before starting the installation, you need to know how much the window sill should protrude above the battery, how far from the battery to the wall and floor to put the heating circuit and which scheme is better to choose.

Radiator placement guidelines

Experts pay great attention to the correct location of heating devices. In this case, the room will be heated with the greatest efficiency.

Basic recommendations for choosing a location for installing batteries:

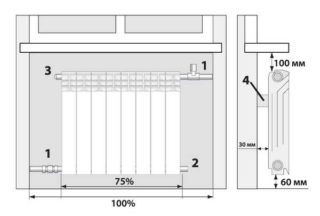

- For high-quality air circulation around the battery, it is necessary to maintain a distance of 3-4 cm between the heat-insulating layer and the heating device. With a decrease in this gap, air exchange becomes more difficult and the efficiency of the system decreases.

- If it is impossible to create insulation, the inner surface of the wall is covered with a layer of foil. It serves as a heat reflector that directs flows into the room.

- When installing batteries under the window sill, a gap between the radiator and the floor of up to 10 cm must be observed. The distance from the radiator to the window sill should be at least 8 cm. This is due to the fact that the board is an obstacle when the warm air rises upwards.

- If the house has large windows, batteries 30 cm high are used. Then condensation will not form on the glasses.

- The radiator is installed at a 90 ° angle. If abnormal, air will accumulate and corrosion will form.

- The battery should be installed exactly in the middle of the window. Then it will cut off the streams of cold air and will not allow them to penetrate into the room.

For decorative purposes, radiators can be shielded with special screens. They must cover the radiator, therefore, they reduce the efficiency of the system, since they prevent the flow of thermal energy into the room. For this reason, it is important to pay special attention to the choice of decorative grilles for batteries.

Requirements of GOST and SNiP

Depending on the type of window, the distance from the sill to the floor may vary. But GOST sets the coefficient at which heat is best preserved in the room. It is 0.55 W / ° С sq.m. For the best effect, plates with low thermal conductivity are used. Also, during installation, you need to figure out whether the window sill should cover the battery.

The provisions of SNiP regulate the following values of the distance between the battery and the window sill:

- The window sill must have a slope angle of at least 1 °.

- There must be a layer of thermal insulation between the radiator and the wall. It will protect the house from heat loss and extend the life of the heating system.

- The battery must have a protrusion in relation to the window sill.

- All window sills should be at the same level. The distance from the floor to the radiator depends on the shape and size of the device.

- The maximum window sill length is 3 meters.

- There should be at least 8 cm of gap between the battery and the window sill.

Installation standards for heating radiators must be observed for good heat retention in the house. In case of insufficient distance between the window and the floor, a low radiator with an increased number of sections should be installed. Then the heat loss will be reduced.

The importance of the gap between the wall and the battery

When installing radiators, it is important to create a distance between the heating device and the wall. The outer wall is constantly in contact with the ambient air, which causes significant cooling. When attaching the battery to the inner surface without a gap, most of the heat will be spent on heating the wall material, not the room. Low thermal insulation properties of concrete walls do not allow creating an optimal microclimate, about 70% of thermal energy will be wasted. When the heating system is moved a short distance, air insulation will be created, which increases the heating efficiency.

There are other reasons why it is necessary to create a gap according to the given standards:

- Creation of a sufficient level of circulation of air masses. If this condition is violated, part of the energy will be lost.

- When placed close to a wall, the appliance starts to heat up faster. As a result, the radiator may be damaged.

- Dust and debris will accumulate between the wall and the radiator, which also impedes heat transfer.

- Without a heat-reflecting plate, the radiator will waste heat on the outer walls.

- If an electric battery is installed, there is a risk of a short circuit. Hot water heating systems can corrode if there is no gap.

When installing heating devices, you must adhere to the following recommendations - the greater the power of the radiator, the wider the gap should be. Its specific dimensions are made up of two important parameters:

- Window sill width, niche dimensions. The possibility of creating a distance depends on these individual characteristics.

- The power of the battery itself.

It is possible to reduce the distance from the wall to the radiator by gluing a foil-coated heat-reflecting material to the wall. Then the gap can be 2.5-3 cm.In other cases, this value is approximately 6-8 cm.

Recommendations for the installation and operation of radiators

The heating efficiency and the service life of the heating system depend on the correct installation of the battery. There are a number of recommendations that you need to use during installation:

- It is recommended to lubricate the gaskets with silicone sealant before installation. This step is optional, but will help protect the connection points.

- Do not suddenly open the valves when filling the heating battery with liquid. Otherwise, water hammer may occur and damage the system.

- If thermostatic expansion valves are installed in a one-pipe system, a bypass must be installed. Without it, the entire riser will be regulated, for which the owner can be fined. Ball valves are placed in front of the valves, allowing them to shut off the supply and return.

- If the radiator has more than 12 sections with one-sided side connection, set the flow guide to a length equal to two-thirds of the battery (it is better to do it before the last section). This will allow the radiator to fully warm up.

- If the radiator is filled with water, it must be vented. If this is not done, the device will not warm up. The air is removed every year at the beginning of the heating season.

After installing the radiator, pipes are brought to it. They are selected in advance by material, section and length.

Connection diagrams

There are several schemes for connecting radiators that comply with the requirements and norms of GOST and SNiP. They are represented by the following varieties:

- Side connection.It is characterized by maximum heat transfer. With this connection, the input is from the top of the battery and the output is from the bottom of the same side. It is the most demanded connection scheme.

- Diagonal connection. Produced with significant system dimensions. Water enters the radiator through the top and is discharged from the bottom from the opposite side.

- Bottom connection or "Leningradka". It is produced in small one- and two-story houses, as well as when installing pipes hidden under the floor. The efficiency of such a system is 5-15% lower than with a side connection.

When pipes are in the rough screed, heat loss increases due to contact with concrete and the ceiling covering of the lower floor.

Step-by-step installation algorithm

After calculating all the necessary values and choosing the connection method, you can proceed to the installation of radiators. All work must be carried out in accordance with the requirements of SNiP. You also need to follow the manufacturer's instructions. If the instructions are violated, there is a risk of loss of warranty service. According to the norms, you can not remove the protective film from the devices during installation. Thus, the device will be protected from dust and scratches during installation work.

Elements required for connection:

- Hooks with plastic dowels - at least 3 pieces. Needed for wall or floor mounting.

- 2 side plugs with right-hand thread. Have the designation D.

- 2 plugs with left-hand thread with letter designation S.

- Plug.

- Silicone sealing thread or flax.

- The elements required according to the scheme are a tap, valves, valves.

- Pipes. Metallic or polypropylene are selected. Metal products are of high quality, durability and durability. Polypropylene pipes are cheaper.

Of the tools you will need:

- Electric drill and drill. They are selected according to the hardness of the wall.

- Screwdriver.

- Building level.

- Key.

- Roulette and pencil.

The general procedure for installing different parts of the heating system is also regulated by SNiP.

- Marking for brackets. This is done with dowels or cement mortar. There should be at least three brackets in total.

- Installation of plugs, adapters, Mayevsky taps and other details.

- Installing the radiator itself. It is necessary to connect its pipes to the heating system.

- Installation of an air vent. It should be automatic.

- Removing the protective film.

If these requirements are met, the installation of the system will be of high quality and durable.

For the efficient operation of the heating circuit, it is important to make the correct connection, which differs depending on the type of fixing. It can be wall-mounted and floor-mounted.

Wall mount

Wall mounts are easier to make than floor mounts.

Installation is carried out as follows:

- Preparation of the attachment site. First, the heating circuit pipe is connected. The wall behind the radiator must be covered with foil material.

- Preliminary marking of the place of fixing the clamps.

- Installation of fasteners using dowels. The wall must be at least 6 cm deep to secure the battery.

- Fitting the radiator onto the brackets. Fixation and alignment of the device.

- Connection to pipes. Checking the tightness of all connections.

- Test start of the system.

It is important to align the battery horizontally during installation. Otherwise, air will accumulate in the device, which reduces the intensity of heating and leads to the formation of corrosion.

It is also important to respect the location of the battery. It should be installed strictly in the center of the window.

Fasteners are different. They can be made in the form of suspensions, brackets and other structures.Regardless of the type, they have one task - to securely fix the radiator on the wall. Instructions for attaching the clips are attached along with the elements themselves.

Floor mount

Heavy and massive radiators cannot always be hung on the wall. Not every clamp can withstand such a load, therefore, they use the floor installation method. For this, special brackets are used. They are more expensive, but their fastening reliability is higher than that of wall-mounted models.

Stages of floor installation of the radiator:

- Selection of brackets that are designed for the weight of the battery.

- Installation on the base place reserved for the radiator. Fixation is carried out on anchor bolts at a distance of at least 6 cm from the wall. The height of the radiator from the floor must be respected.

- Concrete work. Filling the base of the brackets and bolt heads with a tie.

- Putting on hooks on the posts. They are adjusted to the desired height and fixed with bolts. If provided with a complete set, protective metal gaskets are installed.

- Installation on hooks at the pre-calculated height of the battery from the floor. The radiator, as in the case of wall mounting, must be aligned horizontally.

The floor-standing system has an important advantage. All the weight from the battery falls on the floor, rather than being distributed along the wall. By moving away from the floor, a gap will be created to allow air to circulate. Typically, this scheme is used for heavy cast-iron heating radiators, but aluminum or bimetallic devices can also be mounted on the floor.

Regardless of the type of construction, type of batteries and the chosen scheme, it is important to observe the distance between the wall, window sill and floor. In any case, space is needed for heat transfer. If you do not adhere to the established requirements, the efficiency of the system will decrease, the radiators will last less than the stated period. As a result, the cost of energy, repairs and replacement of heating circuit components will increase.