Cold bridges can pass through the floor surface in a house just like through walls or a roof. Therefore, in order to save heating, it must be insulated. There are many technologies, from simple to complex, from budget to expensive. In connection with the deterioration of the environment, people tend to use safer materials in the arrangement of their homes. Expanded clay as insulation fully meets these requirements. There are several ways to organize a thermal insulation barrier from it for a floor surface.

- Properties and advantages of expanded clay

- Material characteristics depending on the size of the fraction

- Insulation of the floor with expanded clay

- Dry styling

- Wet styling technology

- Combined insulation method

- Warm screed on expanded clay

- Warming with expanded clay floor between logs

- Recommendations for floor insulation

Properties and advantages of expanded clay

Lightweight expanded clay material is rounded granules obtained by firing low-melting clay grades. It is made in special rotary kiln drums. The main properties include:

- Good thermal insulation ability - it directly depends on the size of the fraction. Numerically, the average thermal conductivity is 0.18-0.1 W / (m * K).

- High strength index - from 600 to 250 kilograms per cubic meter.

- Soundproofing qualities.

- Resistant to chemically active liquids.

- Ability to withstand negative and high temperatures, as well as direct exposure to fire.

All this makes the material versatile and suitable for use in various fields of construction.

Material characteristics depending on the size of the fraction

Expanded clay for insulation is produced in granules of three main categories by grain size:

- The sand fraction is characterized by an average element size in the structure equal to 10-5 millimeters.

- The gravel fraction has an indicator of the size of the granules in the range of 20-10 millimeters in the total mass.

- The crushed stone fraction is the largest and contains grains with a diameter of 40 to 20 millimeters.

If we take the mass of a cube of bulk material, the heaviest is fine sand, which weighs 450 kg. Further, gravel is 50 kg lighter and rubble by another 50 kg. The performance characteristics are practically the same for all categories of this building material.

Thermal insulation of the floor with expanded clay

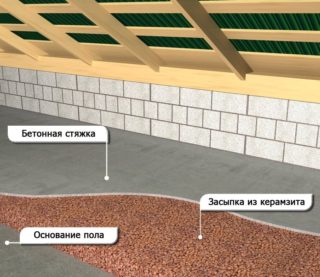

Regardless of the method of organizing a thermal insulation barrier based on sintered clay, there are certain similar technological points:

- A waterproofing device is the very first layer of the cake, necessary to prevent moisture from entering the backfill. Water-soaked granules become more thermally conductive.

- Expanded clay cushion filling as floor insulation. It is carried out using beacons set at the required height.

- Fixing the thermal insulation layer with a screed or other pre-floor covering.

All these stages have certain subtleties, depending on the specific method chosen for insulating the floor with expanded clay in a wooden house or other housing.

Dry styling

The method is fast and easy to implement. It is based on the device of a thermal cushion by a simple embankment and leveling of sintered clay along the plane of the base of the floor. Maintaining the level is carried out by orientation on the pre-exposed beacons. After filling, equip the floor.It can be chipboard or OSB boards, as well as special polystyrene foam. Layer thickness for dry installation should not be less than 0.1 meter.

So that over time the floor does not push through the pillow, you should give preference to the smallest fraction of the insulation.

Wet styling technology

A more complex and expensive method than dry styling. It involves the use of sintered clay as a filler for concrete. The liquid mixture is poured like a regular screed, leaning on the guides installed on the level. The method is used mainly on floors, where there is a sharp difference in height and significant unevenness.

The disadvantage of such insulation can be considered the fact that a rounded pebble, saturated with moisture, loses to a large extent its insulating properties, and the cement mortar perfectly conducts cold.

Combined insulation method

This method combines dry and wet styling elements. From the first technology, the stages of the waterproofing layer and the filling of the insulated cushion from sintered clay of the required thickness are taken. Next, a slurry is prepared, with which the leveled surface is simply poured, in order to form a strong surface crust. After the latter has completely hardened, a concrete screed is arranged above it.

The positive aspect of the method is the preservation of the properties of poor thermal conductivity by the granules. Another advantage of the technology is that clay pebbles do not float to the concrete surface, which is observed in the wet method.

Warm screed on expanded clay

Thermal insulation of the subfloor in this way consists in adding clay granules as a filler to the concrete instead of ordinary stone gravel. The proportions of sand to cement in such a mixture are 2: 1, and the amount of insulation is determined by the load that the floor will be subjected to during operation and is 5-3 parts.

Screed organization technology is standard:

- Waterproofing is laid on the floor.

- The reinforcing grid is placed on the supports.

- Along the entire plane, guide beacons are fixed with lines.

- The prepared solution is used to fill the space between the beacons, without adding 3-2 centimeters.

- After the concrete has set, the surface is topped up to zero with ordinary cement mortar.

The surface can be used in a month.

Warming with expanded clay floor between logs

In this case, the method is based on the installation of a frame made of beams on the ground, concrete. The wood should be insulated from moisture with a film and treated with high-quality antiseptics. The lag is fixed rigidly using corners and self-tapping screws parallel to each other in a horizontal position along the level. The height of the space from the ground to the upper plane should not be less than 0.1 meters.

Insulation is poured between the bars, then everything is covered with a vapor barrier membrane and wood boards are mounted. The convenience of such an organization of the heat-insulating layer is that there is no need to level the bulk material, concrete is not used, and the overall labor intensity of the work is reduced.

Recommendations for floor insulation

If the insulation is incorrectly performed with expanded clay, the floor may remain cold, so you need to know some subtleties.

- The thickness of a pellet pillow of 10 cm corresponds to the thickness of wood of 30-25 cm, depending on the moisture content of the latter. It has been experimentally proven that it makes no sense to make an interlayer less than 0.1 meter.

- The best heat insulator is air; all other materials conduct cold in one way or another. Therefore, you should prefer clay pebbles with an average fraction, where there will be many air cells in the thickness. A very large fraction will not work, since drafts can walk under the floor, cooling the insulator.

- In the thickness of the screed, in no case should you leave metal guides or pins driven into the ground, since they are cold bridges.

Conducting concrete work on the installation of insulation requires the mandatory use of a damper tape around the perimeter of the base of the room.