When building or renovating buildings, it is important to properly prepare and level the surface. A special material is used to prevent the formation of condensation. To provide effective protection against moisture access, a vapor barrier is needed. Which side to lay the membrane, sheet or film to the insulation depends on the type of surface.

- Purpose of the vapor barrier layer

- Dew point and vapor barrier

- Which side you need to attach the vapor barrier

- Types of vapor barrier materials

- Polyethylene film

- Polypropylene film

- Vapor barrier membranes

- Foil vapor barrier

- Installation requirements

- Features of laying on the ceiling

- One-sided materials

- Double-sided materials

- Foil film

- Insulation of the roof from the effects of steam

- Working with ventilated facades

- Laying a film vapor barrier on floors with insulation

- Reflective vapor barrier installation

Purpose of the vapor barrier layer

Without a vapor barrier coating, when the temperature changes in winter, moisture penetrates into the insulation, which is in contact with cold and warm air. It is in a state of condensation, but then transforms into water. In a humid environment, germs and mold form, and metal elements begin to rust. The hydro-barrier eliminates these processes.

Dew point and vapor barrier

Inside the walls, at the moment of contact between warm air masses from the room and the outside cold air, the dew point is reached. If condensation of water vapor occurs inside the thermal insulation coating, the material becomes wet. It can deform and shrink, lose thermal conductivity.

Laying a vapor barrier will provide:

- protection of insulation, roofing and wall elements from moisture;

- dew point output outside the walls of blocks, concrete, brick, outside;

- maintaining the strength of the building;

- preventing the formation of unaesthetic and allergenic black mold;

- comfortable microclimate;

- reducing the cost of heating equipment and air conditioning.

A hydro-barrier is the only way to protect a room in a frame-panel house from moisture.

Which side you need to attach the vapor barrier

Before putting the vapor barrier to the insulation, you need to figure out which side to do it. Manufacturers produce products for one-sided or two-sided mounting. The instructions usually indicate which side to attach the material to. If there is no manual, you can define the inner part like this:

- the sides have a different color - a light one is put on the insulation;

- when rolling, the inner layer is at the bottom - it is directed towards the thermal insulation;

- the outer layer is fleecy and does not allow moisture to pass through, the material is smooth from the inside, therefore, lie on the insulation;

- polyethylene film can be placed on either side, steam-condensate film - smooth on the heat insulator so that it does not get wet when condensation forms;

- the foil-clad material is fixed with the reflective part outward, isospan - after making the ventilation hole.

Roofing material is laid on either side with sealing of the seams.

Types of vapor barrier materials

Vapor barrier materials are distinguished by their strength and the ability to drain condensate only if the installation technology is observed. To protect a house or other building from the appearance of a dew point, you can use several vapor barrier.

Polyethylene film

A deaf vapor barrier that completely blocks moisture. The material has a thickness of 150 microns and is inexpensive.The disadvantage of polyethylene is the minimum service life, deformations and ruptures in very warm rooms. It can be replaced with a steam film with a smooth inner surface and a rough outer surface. Moisture does not penetrate the barrier, but is retained on the smooth part.

Polypropylene film

The vapor barrier does not deform when exposed to cold and heat, it is durable. It consists of several layers:

- reinforcement - a mesh of a film for fastening to a frame or lathing;

- polypropylene - provides vapor barrier characteristics of the material;

- lamination - located on the outside, increases the vapor permeability.

The thicker the polypropylene, the less condensate it will let through.

Vapor barrier membranes

They are produced in the form of a two-layer non-woven material, intended for laying on insulation, supporting structures. They are distinguished by their durability, easy installation, prevent the formation of dew when heating water, human breathing.

The membrane works on the principle of moisture absorption and further evaporation. Due to the two-layer structure, the insulation is not wetted. The lint absorbs condensation and removes it, while the vapor-resistant layer does not let water through.

When choosing vapor barrier membranes, you need to focus on the following factors:

- Sd (equivalent diffusion thickness) - a material with a higher index will have a lower vapor resistance;

- permissible operating temperature - from -40 to +150 degrees;

- strength indicator - only a whole and sealed membrane will protect against condensation.

Installation of membranes should be carried out taking into account the temperature, heating mode and room humidity.

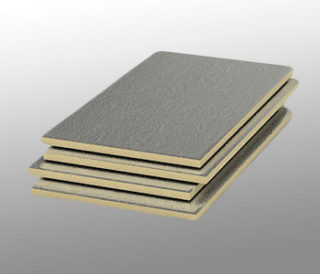

Foil vapor barrier

Due to its layered structure, the material provides an effective vapor barrier. For the manufacture of the base, polypropylene, lavsan are used, for the upper part - aluminum foil. The material prevents the formation of steam and condensation inside the house, is a reflector of light radiation, protects the roof from the wind, reflects UV radiation in the summer.

The advantages of foil vapor barrier include:

- low weight - the canvas can be laid without prior reinforcement of the structure;

- small thickness - the roofing cake and the supporting parts of the walls do not become heavier;

- no need to organize a ventilation gap between the casing and the vapor barrier;

- plasticity - when laying it easily takes any shape;

- the ability to withstand temperatures up to +150 degrees - the material is suitable if there is a bath or sauna on the site;

- speed of cutting with a clerical knife or scissors;

- ecological purity - does not harm human health and the environment.

Foil-clad materials are a great way to save on heating costs. with their help, you can insulate the building.

Installation requirements

To correctly lay the vapor barrier film, the following rules must be observed:

- The roof slopes are made out with a continuous carpet - the roll material must be connected with tape.

- Laying is carried out horizontally with a slight overlap.

- When installing from the attic side, the insulation is laid in strips overlapping the walls and ceilings by 15-20 cm.

- For fixing from the inside, it is allowed to use a stapler.

- The best option for insulation for vapor barrier is rigid self-adhesive boards.

- Punctures, through cuts must be sealed with sealant or polyurethane foam.

- No ventilation gap is required when using double-sided or super diffusion membranes.

- The dew point is determined before laying.

- In the presence of wooden structures, the barrier must be laid with a smooth surface to the insulation.

- If the insulation is outside, the vapor barrier must be inside.

- On window and door openings, the film is stacked with a margin.

The film must be protected from sunlight.

Features of laying on the ceiling

A diffusion membrane is suitable for the final ceiling. It is located on insulation - rolled mineral or basalt wool. An insulating coating is placed between the rafters and joists. The vapor barrier is fastened so that there is an overlap on the walls and the joints coincide with the lags. The corners are additionally worked out with tape.

One-sided materials

A propylene film with a laminate is laid with the smooth side on the insulation:

- The material is positioned so that it bends around the beam. The direction of the canvas is perpendicular to the supporting structures.

- Laying with cutting into fragments and subsequent wrapping of the beams with an overlap of 10-15 cm.

- Sealing joints. Double-sided tape is glued to the edge of the vapor barrier and overlapped. The film should sag by 2 cm.

- Fastening the remaining layers so that the seam is displaced by 30-40 cm.

Work is not carried out in a damp room, during fogs, rains and snowfalls.

Double-sided materials

The film has a smooth and rough side. The latter should come out - it retains drops of moisture and ensures their evaporation. The smooth vapor barrier prevents condensation. A ventilation gap of 5 cm is left between the insulation and the vapor barrier.

Foil film

The sheets are laid out so that the metal layer protrudes outward. It will reflect heat radiation, maintain a pleasant microclimate, while also draining condensate.

Insulation of the roof from the effects of steam

It is worth laying the roofing vapor barrier to protect the structure from moisture from outside and inside. Installation work is done step by step:

- The choice of material and side of installation. The foil membrane is placed with the shiny side out.

- Roll out the material parallel to the cornice. Between the cuts, you need to overlap the walls of about 15 cm.

- Fastening the foil vapor barrier to the staples with a special stapler.

- Bonding joints with metallized tape.

- Installation of wooden lathing to fix the membrane and place the outer insulation.

- Fastening of thermal insulation from the outside of the building.

- Laying additional insulation - with mineral wool, you can close up the crate cells.

- Installation of a diffusion membrane that removes steam outside and retains heat in the room.

- Organization of the ventilation gap in the form of a crate. The thickness of the slats forms the desired cavities.

At the last stage, a two-tier lathing is installed in the form of perpendicular strips 25 mm in thickness.

Working with ventilated facades

For houses with ventilated facades, a membrane with moisture and windproof properties is suitable. It will protect the insulation from moisture and warm air leakage. When laying the material, several rules must be observed:

- the vapor barrier must be applied with the smooth part up;

- direction of the material - horizontally and vertically from top to bottom with an overlap of at least 50 cm;

- fastening points are selected according to the number of fasteners of the ventilation facade, otherwise the membrane will burst with the wind;

- the end part of the thermal insulation is located so that the upper layer of the vapor barrier can go 25 cm under it.

Fire-prevention misfires should be 120 cm from internal corners, doors, windows.

Laying a film vapor barrier on floors with insulation

In order to protect the floor surface from moisture and condensation, a film can be installed. Before the start of work, insulation is carried out along the logs - mineral or basalt wool is laid in the cavity. Simultaneously with the vapor barrier, water protection of the first floor of the house is organized.

In the area of the rooms, roll insulating film is used. It is placed with an overlap of 12-15 cm, and then the joints are carefully glued. The material is placed on the wall by 10 cm.

Vapor barrier of concrete floors is performed at the last stage. First, waterproofing is laid, then insulation, and at the end - a film.

Reflective vapor barrier installation

Foiled canvases are suitable for rooms where you need to keep warm as much as possible. The material is laid out with a reflective layer. A ventilation hole is arranged between it and the trim, which increases the heat-reflecting properties of the foil and eliminates the risk of condensation. Cuts of reflective vapor barrier are placed end-to-end and sealed with adhesive tape on a metal base.

Vapor barrier materials trap heat inside the house, prevent moisture from affecting the roof, walls and ceiling. The vapor barrier in living rooms is installed with the rough side inward, in saunas and steam rooms - with the smooth side inward.