When heating a home using floor heating systems, the heated air comes from below, which allows you to maintain a comfortable microclimate and not dry out the air in the house. The heat is evenly distributed in the space, there are no temperature differences in the room. The equipment allows you to adjust the degree of heating in each room separately for maximum comfort for all family members.

Underfloor heating device

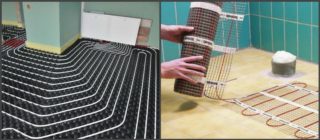

Underfloor heating systems are of several types. The main ones are water and electric. The latter, in turn, are divided into cable, infrared film and heating mats. Regardless of the type, they all have a similar design, which consists of the following layers:

- Base floor surface.

- Waterproofing coating.

- Thermal insulation.

- Heating system of pipes, cables or thermomat.

- Cement screed that envelops and fixes pipes.

- Finishing floor covering.

Underfloor heating can serve as the only source of heating or an additional one together with the central one. The temperature is regulated manually or automatically.

The optimal temperature for heating a warm floor of different types

The documentation supplied with the system prescribes the maximum temperature values that can be set on a specific equipment. Often on the thermostat you can see a value of + 40C. However, building codes establish restrictions: the maximum temperature of a warm floor for residential premises should be no more than +26 C. But there are several nuances. The setting of the parameters is influenced by the room itself. For example, in the bathroom, a higher degree of heating (+30 C) is set for a short time in order to get rid of excess moisture. A more powerful system will be required on a cold balcony, because the floor there will quickly give off heat and cool down.

The maximum heating value is influenced by the floor coverings. Ceramic tiles are considered the best option. It is not subject to deformation from high temperatures, quickly heats up and cools down. For linoleum, laminate or carpet, the value should not exceed + 26C. Otherwise, they dry out and crack from overheating.

Temperature indicators depend on the type of underfloor heating. For the water system, the main element is a pipe laid on the base of the floor and poured with a 6 cm thick cement screed. The source of heat in the system is the water moving through the pipe. In this case, the normal heating of the warm floor should be + 30C. Considering the further installation of the floor covering, its value decreases by several degrees and becomes comfortable.

To warm up the flooring to + 26C, it is necessary that the temperature of the coolant in the pipe reach + 55C when feeding and + 45C in the return. At the same time, water floors warm up for a long time. Full heating takes 12-20 hours (time depends on the area of the room). However, the warmth begins to be felt after 3-4 hours. This situation is explained by the relatively low thermal conductivity and the need to warm up the cement screed. But the water floor also cools down for a long time - after a complete shutdown, the heat can stay for more than a day.

The cable type of the system assumes a maximum heating of the main element up to +85 C, and its insulating material must withstand a temperature of +100 C.

Installation of thermomats allows you to quickly warm up the floor to the optimal + 26-28 C and provide a comfortable environment in the house. An electric floor heats up much faster than a water floor. The system itself reaches the specified parameters in an average of 10-15 minutes, and the complete heating of the screed takes about 10 hours, regardless of the area of the room. The warmth begins to be felt after 3-4 hours. Cooling down is also quite fast - about 12 hours.

The infrared design is a modern thin film design that combines most of the advantages of other systems. Due to its low thickness, the film can be installed under linoleum, carpet, parquet, laminate, etc. It is not at all necessary to pour the screed, it is enough to lay a layer of plywood and vapor barrier between the film system and the floor covering. The maximum heating temperature of the system is +55 C, so overheating of the coating and its destruction is excluded.

Infrared underfloor heating has a unique method of heat transfer, which is radiation. It heats objects that give off heat to the air. This type of system heats up in record time, the warmth is felt already in the first hour of its operation. Cooling down is the same as for a cable floor.

Microclimate control methods

The temperature of the water-type underfloor heating is controlled by completely stopping the supply of the heat carrier, or by mixing hot feed with cold return to the required value.

The first option is the simplest and most reliable. A pump and a check valve are installed in the system for supply, and a thermostat is mounted on the return manifold. A hot coolant is supplied to the warm floor (+ 70-80 C), the water gives off energy to the room while gradually cooling down. As soon as the system overheats and the return temperature exceeds the value set by the thermostat, the pump is switched off. The coolant supply stops, the equipment goes into standby mode. As soon as the water cools down, the pump starts up again.

The second option involves installing a three-way valve or mixing valve upstream of the pump. These devices provide a mixture to the hot flow of the cool return. Thus, the supply water is diluted to the desired temperature. The mixing degree is adjusted manually or automatically.

Heating of electric underfloor heating is controlled by a thermostat and a temperature sensor connected to it, which is installed near the heating cable. As soon as the system warms up to the value set by the thermostat, the voltage supply to the heating elements is cut off.

Depending on what equipment is installed in the system, the temperature is controlled in several ways.

- The manual adjustment is done manually based on the personal feelings of the users. To understand how effective the changes are, you need to maintain a two-hour break between them. With this regulation, the data will be inaccurate.

- Individual or zone settings for underfloor heating occur due to sensors installed in each room. In this case, the microclimate is regulated separately for each room by room-by-room automation. It maintains the set temperature of the coolant, air or surface. In this case, continuous user involvement is not required. In addition, automation saves energy resources.

- Group regulation is characterized by the accuracy of the readings. It increases or decreases the temperature, increases or decreases the supply of hot coolant in automatic mode.In a group setting, a common value is set for the entire system as a whole.

- Another way is a valve with a thermal head. If it is necessary to change the heating level, the capillary tube that controls the valve opening expands or contracts. This continues until the desired mode is set. The adjustment is carried out automatically. Depending on the temperature of the air in the room, the automation determines the degree of heating and opens or closes the valve.

There is a method that combines individual and group microclimate control modes - a complex type. In this case, equipment is installed to adjust the heating of warm tar throughout the apartment. Additionally, automation is mounted for each room separately.