Heating boilers installed in private homes also for water heating purposes differ in a number of parameters: the type of fuel used, functionality, installation features. To choose the right heating boiler, you need to take into account the power of the unit required to service the house, and the ability to provide the required working conditions.

Heating boiler classification

Commercially available devices are sharpened for the use of different types of fuel. They differ in availability, cost and efficiency.

Gas

Gas fired boilers represent the largest market segment. This is due to the low price of this type of fuel in combination with good efficiency. Such a model can serve a large dwelling, in particular, work on two floors.

On sale you can find devices of two types of structures - floor and designed for wall mounting. Wall-mounted boilers are good for their compactness and completeness. In addition to the heat exchanger and the control unit, the housing of such a unit often contains additional components that optimize the functioning and make it safe. For a boiler placed on the floor, such equipment often has to be purchased separately. In this case, the total cost will be higher than the wall unit.

Both types of devices can have one or two circuits. Boilers of the first type are designed for use only for heating the premises.

Double-circuit installations are intended for residents who need hot water for domestic needs. Among such boilers, the best choice is the model equipped with a built-in boiler. It will provide residents with a supply of about 50 liters of heated water in case the gas supply is turned off.

Floor standing units can have a cast iron or steel heat exchanger. Steel products are lighter and less susceptible to shock during transportation, but more susceptible to corrosive effects. One of the subspecies of floor-standing devices is a parapet boiler with a closed combustion chamber, for the installation of which an ordinary chimney is not required. Features of its structure allow placement in a small room. However, such a device requires a gas supply and access to electricity to operate.

Solid fuel

Solid forms of fuel have been used by mankind for many centuries. Firewood, peat briquettes, lignite and hard coal fall into this category. The advantage is the possibility of creating a heating system that does not depend on the supply of gas and electricity. In areas where it is possible to provide the boiler with sufficient fuel resources, this option will be optimal. Some options have a long burning mode.

The following models are produced:

- Standard boilers that do not require an electrical connection. They can be designed for the operation of a certain type of solid fuel or work with different types of it. Temperature control is realized by means of sensors.

- Units with pyrolysis wood combustion.They burn not only the material itself, but also the wood gas produced in the process. They have good efficiency and are capable of heating a large room, but they require electricity.

- Devices capable of operating not only on solid, but also on other types of fuel.

On the market you can find models in steel and cast iron, with one and two circuits.

The downside of solid fuel boilers is that they require regular loading of new portions of firewood or coal.

Liquid fuel

Most often, such devices run on diesel fuel. Sometimes fuel oil is also used, as well as technical oil that has worked out its due date or has become unsuitable for operation for its intended purpose. Such units are powerful and have high efficiency, due to which they are able to serve a spacious cottage building. Another plus is the relative cheapness of solar fuel compared to electricity. The downside is the need to install equipment in a special room equipped with an exhaust mechanism. In addition, the burner is quite noisy. When the fuel cools down and its temperature begins to approach zero, the wire must be artificially heated, otherwise the device will stop due to clogged filters.

Electrical

These devices are good for their compactness, complete structure, no need for a hood, burner, fuel tank. They do not generate emissions, do not require cleaning from fuel waste. An electric boiler can even be installed in the kitchen. The downside is that not all localities have access to sufficient electricity.

Combined

These units are capable of working with different types of fuel. One of the options is a combi boiler with a set of gas and liquid burners. It can be delivered in case of frequent interruptions in the operation of the gas pipeline, or in the case when it has not yet been laid, but it is planned to use it in the future. Some of these models are equipped with a heating element, which allows you to work on electricity. This segment of products is naturally the most expensive.

Popular countries boiler manufacturers

The rating of the best gas boilers for heating a private house demonstrates that the most popular European manufacturers are firms from Italy and Germany. In Asia, competitive products are manufactured in South Korea.

Italy

The best reliability indicators among Italian boilers are demonstrated by the products of the Baxi brand. It is presented in different types of models - suspended condensing and floor-mounted. In terms of quality, they are comparable to German units. A distinctive feature is high automation of control. The first years after their appearance on the Russian market, Beretta and Ariston also enjoyed popularity, but over time they lost ground - users began to complain about the quality of parts.

Korea

Among the Korean boilers, Kiturami products are distinguished by their reliability and high technology. In terms of functionality, they compete with boilers from Germany. Due to the rather high price and less promotion in comparison with European brands, users do not often prefer this brand. Navien wall structures, which have received excellent reviews from consumers, have a more affordable price.

Germany

German gas boilers are known for their reliability, wide functionality, high level of automation. The efficiency of these units can reach 97%. Wall-mounted German boilers from Bosch and Vaillant are also available in a version equipped with a water boiler. Floor-mounted models are manufactured by Viessmann, whose products, with excellent performance characteristics, are also among the most expensive in an already expensive product segment.

Among domestic manufacturers, the Gradient brand can be noted. A wide range of thermal equipment for different types of installation is produced by Protherm from Slovenia. The products of these brands are not as high-tech as German ones, but they are reliable, affordable and suitable for use in the Russian climate.

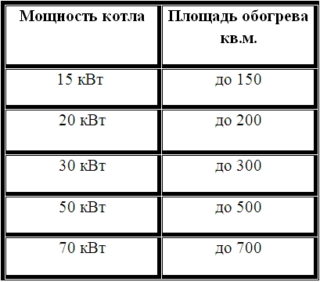

Boiler power calculation rules

The simplest and roughest calculation method is based on the area of the serviced rooms. It is assumed that 100 W of heat is spent on heating 1 m2. Then, to find the required boiler power in kilowatts, the total area of the premises is divided by 10. The formula is suitable for rooms with a height of 2.5-3 m and climatic conditions in the middle zone of the European part of Russia. When used in the southern regions, the resulting result is multiplied by 0.8, in the northern regions - by 1.6.

The calculation based on the volume is based on a similar principle, only the height of the premises is also taken into account. Standardized costs for heating a cubic meter are assumed to depend on the material from which the house is made: in the case of panel buildings, it is 41 W, for brick dwellings - 34. There are also complex types of calculation that take into account different categories of heat loss.

Selecting the number of contours

Most consumers choosing heating with a boiler would like to receive sufficient hot water supply. In this case, you need to either install a two-circuit system, or use an indirect water boiler by connecting it to a single-circuit floor boiler.

Hot water can be produced in the system in two ways. The flow-through method is suitable if the needs are limited to small volumes. Using a boiler will allow you to always have sufficient reserves of heated water, including to survive periods of power or gas outages.

Advantages and disadvantages of heating boilers

The advantage of using this type of heating is the sufficient boiler output. Even low-power models are able to serve several rooms, powerful ones are able to cope with a spacious home. A number of units do not need much supply of external resources, they are compact and complete. With the correct selection of the components of the system, the consumer will also receive a supply of heated water.

Disadvantages are the high cost of boilers and the need to supply resources (electricity, gas, solid or liquid fuels). Switching to work from another source when the main supply is interrupted is not possible for all models.

In addition to the number of circuits, the type of installation and the fuel used, heat generators also differ in a number of parameters. The user needs to pay attention to fuel consumption and the presence of an energy-saving mode. Also, the devices differ in terms of the nature of the smoke removal and the device of the combustion chamber (closed or open). It is important to have mechanisms to ensure operational safety. They can be installed in the unit, or must be purchased separately.

Site selection and operation

The most compact models are those designed for wall mounting. In this version, electric and gas units are produced. They are perfect for small dwellings, the capacity of such a device is sufficient for high-quality home maintenance. Installation does not require the allocation of a special non-residential room. You can hang the boiler in the kitchen, and the electric one can even hang in the living room.

The most powerful devices are in the floor-standing category. Such a heat generator should be installed in a separate room. Fire safety regulations prescribe that there should be some distance between the boiler and the walls. Often, such models require an exhaust device in the room.

For work in areas where electricity is often cut off, it is advisable to purchase an electric generator. This will keep the device in good working order at all times. When the priority when choosing is the possibility of autonomous operation (without power supply), it is better to give preference to a solid fuel unit.

When arranging a boiler room, it is also important to correctly organize the chimney and take care of the means to ensure the safe operation of the equipment. These include traction control devices, flame detectors, mechanisms that turn off the unit when the pressure in the gas pipeline is too low, and a temperature control unit.