The performance characteristics of the floor covering, which retain heat well and are resistant to mechanical stress, depend on how the base for the warm floor is prepared. For its formation, a cement screed is used, including insulation materials and strengthening additives. Before choosing a suitable thermal insulation coating, you will need to familiarize yourself with their characteristics.

Substrate materials

When arranging the base of a water floor, experienced builders act as follows:

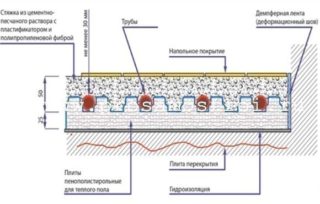

- A special substrate made of extruded polystyrene foam is laid on the rough base.

- A lavsan film (vapor barrier) is mounted on it.

- It is closed with a layer of foil.

The last of the listed components is necessary for even distribution of heat throughout the floor in the apartment.

A good substitute for such a substrate is foamed or extruded polyethylene, which is not inferior in its characteristics to expanded polystyrene. The distinctive features of the latter include a very low thermal conductivity, in which it is second only to mineral wool coatings. The screed for water-heated floors on top of the insulating layer turns into a heating monolith of a large area.

Since expanded polystyrene, like polyethylene, can withstand heating up to 900 degrees, water pipes are laid directly on the floor base without harm to the insulating material. In the manufacture of underfloor heating on interpanel floors, polystyrene foam plates with a thickness of about 20-30 mm are taken. On the first floors of buildings located directly above the foundation, it is allowed to use foam as a base. This will require plates with a thickness of at least 100 mm. Other materials that, according to SNiP, are allowed to be used as a substrate:

- lightweight and durable cork coverings;

- mineral wool slabs (mats);

- Fiberboard;

- penofol or penoplex.

The choice of a specific material is determined by the current state of the subfloor and the type of flooring to be laid on it.

The purpose of the damper tape and expansion joints

Insulation around the perimeter of the room (damper tape) is needed to compensate for the thermal expansion of the concrete mass and reduce heat loss through the walls. The thickness of the protective layer in this place, according to the standards, is at least 5 mm and corresponds to the height of the screed. The latter is made of non-hygroscopic foam polyurethane, along the perimeter of which protection is made in the form of expansion joints. The use of insulation along the walls of the house is considered mandatory, while the expansion joint is applied only in the following cases:

- the total area of the room exceeds 35-40 m2;

- the length of its sides is more than 8 meters;

- the geometric dimensions of the room satisfy the ratio a / b> 1/2, where “a” and “b” are the lengths of adjacent walls.

The room is divided into small sections, after which additional expansion joints are made on each of them. The layout of the heating circuit pipes is calculated so that their number per seam is minimal. The option is considered optimal when only two threads pass through it (direct and reverse).It is also important that the pipe is laid through the seam with a slight bend and placed inside the corrugation with a length of at least 30 centimeters.

Screed mortar

When preparing a screed solution, it is important to thoroughly mix the components taken in certain proportions. For these purposes, the following components are traditionally used:

- cement composition;

- construction sand;

- water.

The disadvantage of cement mixtures is the tendency to shrinkage, which is taken into account already at the stage of preparing the working composition. If the solution is not mixed very well and is then applied in a thin layer, the surface will most likely be covered with microcracks. To avoid this, experts recommend laying a reinforcing mesh in the screed body. In addition, it is allowed to include special strengthening components in the solution.

Cement is the base of the coating, which is responsible for the strength and specific characteristics of the pour. The second component is thoroughly washed and dried sand, which is a fine aggregate. When choosing the right proportion, the features of the rooms where the finishing work is carried out are taken into account.

If we assume that the floor will be used very intensively, for the preparation of the mixture, one proportion of cement is chosen, which corresponds to three parts of sand. This ratio is well suited for the preparation of a durable and reliable protective coating.

Protection thickness

The thickness of the screed for a water-heated floor plays a decisive role in the formation of a reliable protective coating from the solution. The efficiency of the boiler depends on the correct selection of this parameter. With a relatively thin layer, fuel consumption is reduced, but on the other hand, the heat transfer from the circuit is not very high. Because of this, heating is uneven, which is fraught with gradual destruction of the protective coating.

The thick layer absorbs most of the generated heat, significantly reducing system efficiency and increasing energy costs. The optimal thickness of the screed for warm water floors is chosen based on external factors:

- type of rough base - concrete slab, wooden floor or just soil;

- established temperature regime;

- the estimated height of the ceilings;

- the slope of the base of a wooden or other floor;

- the thickness of the pipes to be installed;

- type of solutions used.

The configuration of the room itself is also taken into account.

Taking these factors into account, experts distinguish 3 types of screeds: the minimum - 2 cm, formed using leveling mixtures (without reinforcement), as well as the optimal thickness of about 5-7 cm and the maximum - up to 17 cm.

According to SNiP, for the first type, the characteristic parameter can be increased to 30 mm if a reinforcing mesh is laid under the pipes. The maximum option is resorted to in exceptional cases when the subfloor is very uneven (in a capital garage, for example).

Types of screeds

In accordance with the quality of the finished mixture used in the arrangement of the coating, the screed to be equipped can be:

- dry;

- semi-dry type;

- wet.

For the arrangement of a wet-type protective coating, a cement mortar is used with the obligatory addition of a small amount of sand. This is the easiest way to arrange a screed in a private house, which does not require the professionalism of the performer. The mortar is mixed in a suitable container using a perforator, which eliminates the need for a concrete mixer.

If funds are available, you can purchase not individual components of the mixture, but a ready-to-use dry solution. It contains the necessary proportions in advance for all components and additives. For cooking, it is enough to pour water into it and stir thoroughly.The indisputable advantage of such a screed is its small thickness, which does not reduce the useful volume of the equipped room.

The working composition of a semi-dry type of screed is similar to its "wet" analogue (cement, quarry or construction sand and a plasticizer). A slight difference lies in the proportion in which the dry composition and the liquid are taken - only one third of the water is contained. Making a semi-dry screed is not at all easy, since in this case a concrete mixer is required - it is very difficult to prepare such a composition with your hands, and sometimes even impossible. For its high-quality arrangement, you also need a vibrator.

You have to buy a semi-dry mixture ready-made, since it is very difficult to guess with the right proportions on your own. Such a screed should be abandoned altogether if manual work is expected.

When choosing a "dry" option, it is important to remember that loose components such as expanded clay are used for its implementation. The advantages of this method include the availability of materials and their low cost. The simplicity of arranging the screed allows you to make it yourself.

This technology has disadvantages, which are expressed in two significant disadvantages:

- during preparation, a thick protective layer is obtained, reaching 8-12 cm, therefore this method cannot be used in rooms with low ceilings;

- low thermal conductivity of the starting material.

The final decision on the choice of one of the options is made by the contractor himself, taking into account the size and features of the structure.

Filling technology

The operations for arranging the substrate are considered on the example of the wet version. Sequencing:

- The floor base is cleaned of accumulated debris, after which they proceed to the arrangement of waterproofing.

- On the concrete floor, a plastic film is covered with overlapping pieces and wrapped on the wall plane by 11-15 cm.

- A damper tape is fixed along the perimeter by means of a construction stapler (PVA glue).

- If there is a clearly visible slope, the screed thickness required for leveling is determined.

- A heat-insulating substrate of the required thickness is mounted on top of the film, and a reinforcing mesh is laid on it.

- Underfloor heating elements are laid according to the selected scheme.

- Go to the preparation of the solution.

- At the end of the installation work, the screed itself is poured.

In the next two weeks, the surface is poured with clean water, and then covered with a protective polyethylene film. After the working plane is completely dry, a decorative coating of any type (laminate, for example) is laid on the base. In office premises, ceramic tiles or similar materials are used for this.

Foil under the screed is a divorce for marketers.