The installation of stoves and fireplaces requires a smoke extraction system. To build a chimney, you need to choose the right pipes, as well as observe a number of nuances for safe and operation. Incorrect calculations can lead to reduced heat dissipation and accidents.

Requirements for the construction of the chimney

The main purpose of chimneys is to remove gases outside the house. In order for all harmful substances to be removed efficiently, it is necessary to properly equip the chimney channel, and also correctly calculate the height, section and configuration of the pipes.

According to the requirements of SNiP, when installing two boilers or furnaces, it is possible to install one chimney. Its calculation and installation should be carried out by a professional stove-maker in order to comply with all the conditions for safe operation.

According to building codes, when creating chimney flues, you must use the following rules:

- The length of the pipe from the grate to the top point must exceed 5 meters. This rule can only be violated in buildings without attics and with a stable forced draft.

- The distance from the metal chimney to the structure made of combustible materials must be one meter or more.

- The maximum length of the horizontal bend is 1 meter.

- All places where the chimney passes must be made of non-combustible materials.

- The connection of the metal parts of the pipes is carried out using a sealant with an operating temperature of over 1000 ° C.

- The minimum elevation of the chimney above a flat roof is 50 cm.

- A non-brick chimney with a height of 1.5 meters must be reinforced with braces and braces.

- Slopes and horizontal sections reduce traction. All bends and displacements should be done at an angle of up to 45 °.

Taking these rules into account, a chimney plan is created.

Choice of materials

Arrangement of laying a chimney for a stove can be done in several ways:

- With a passage through the attic and roof. Then all floors must be made of fire-resistant material.

- With an outlet outside the walls and exclusively inside the building.

- With the passage through the upper roof, past the floors.

- Supported by a boiler or stove. Wall mounting is also possible.

The selection of the optimal configuration depends on the layout of the house, the place of installation of the heating system, and the individual characteristics of the structure. A specialist will help you choose the best option. Next, you need to select pipes for the chimney.

The smoke exhaust duct can be made of bricks, iron and asbestos pipes for ovens, ceramics, concrete, heat-resistant glass. Installation of all types except glass can be carried out independently. The section is round or square with different diameters.

Brick

A chimney made of baked brick is the best option for a stove. These are traditional designs that have been performed for more than a century. They perfectly fulfill their functions and effectively remove smoke from the room. A brick chimney must be created along with the construction of a dwelling and a separate foundation must be poured for it. For work, a high-quality, solid, well-fired brick is selected.Porous structures can leak hazardous gases.

The advantages of a brick chimney for a metal stove include fire safety, stylish appearance, well-studied design, long-term operation and additional heat transfer. Disadvantages - high price, heavy weight and the creation of a separate foundation.

Brick is used mainly in the installation of metal stoves powered by solid fuels. They are made mounted in the form of a separately located vertical outlet and wall, which are located inside the load-bearing wall.

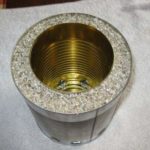

Galvanized and stainless steel

These materials are resistant to the formation of rust and the influence of aggressive media that form when condensate and gas from the furnace are combined. They are lightweight, so the installation does not require the construction of an additional foundation.

There are the following types of furnace steel pipes on sale:

- Single-walled. They are a single layer of steel without thermal insulation. It is necessary to additionally insulate during the installation process.

- Double-walled. There is insulation between the sheets of steel.

The steel chimney needs thermal insulation as heat loss and condensation reduce efficiency. The cost of the entire system will be less than when laying a brick or ceramic counterpart.

Stainless steel stove pipes and flues consist of the following parts:

- rain cap;

- tees;

- knee;

- straight pipes;

- condensate collector.

To make a pipe for the stove, you need to connect all the parts to each other. The joints are treated with a heat-resistant sealant. The steel pipe can be used for almost all types of furnaces and raw materials.

Asbestos cement

Natural asbestos pipes are characterized by low cost and durability. They began to be used back in Soviet times. Initially, the material was not intended to create a chimney due to its fragility and instability to high temperatures. Also, asbestos pipes have a rough inner surface on which soot settles. It is difficult to clean and if not, there is a risk of fire and explosion. Also, under the influence of condensate and vapors, asbestos is destroyed over time.

Chimney ducts made of asbestos are made in a mounted version. The best option is the vertical arrangement of all elements. All slopes are made of non-combustible pipes.

Ceramics and concrete

The ceramic chimney is durable and expensive. These devices do not overheat and are resistant to the aggressiveness of soot and the formation of corrosion. The walls are smooth, so condensation and soot do not accumulate on them.

During installation, the chimney is assembled like steel devices. The difference lies in the need to form a box of expanded clay concrete. Thanks to the box, fire safety is significantly increased. Fire in such chimneys does not occur. The weight of such a structure is small, but the foundation is still required.

Concrete bases are more massive. Such installations are practically not used due to the complexity and laboriousness of installation.

Vermiculite and perlite pipes

The design is a sandwich chimney. In this case, the classic mineral wool insulation has been replaced with a refractory material.

The positive qualities include:

- minimum weight;

- moisture resistance;

- resistance to acids and corrosion;

- resistance to extreme temperatures.

Compared to classic sandwich structures, these types of chimneys are cheaper and can work for at least 25 years.

Aluminum and steel corrugated pipes

Aluminum circuits are less resistant to high temperatures. They cannot withstand more than 110 ° C, therefore they are used as household air vents for hoods or chimneys for gas fireplaces.Corrugated stainless steel chimney pipe withstands high temperatures well.

Corrugated pipes have the following advantages:

- The ability to set the desired direction due to the flexibility of the structure. You can easily connect the sections at right angles.

- Plug the old brick chimney.

Corrugated products are rarely used. This is due to the short service life compared to analogues.

Plastic

Heat-resistant plastic pipes are also widely used for the extraction of cookers and condensing or gas boilers. They can also be used for casing a brick chimney in areas where the temperature does not exceed 200 ° C. The material is not subject to corrosion, has smooth walls and is easy to install. Plastic pipes are inexpensive.

Common mistakes

Experienced craftsmen build structures without any special difficulties and according to all the rules. Novice specialists can make typical mistakes, which include:

- Incorrect choice of the height and thickness of the chimney pipe. This is one of the most common mistakes. If the length is too long, excessive draft is created, which increases the likelihood of smoke being drawn into the firebox. The optimal pipe size is 5-6 meters, depending on the size of the combustion chamber and the configuration of the chimney.

- Bringing the chimney to excessive hypothermia or too much heating. Both cases can lead to the destruction of the pipe.

- Lack of condensate drainage. To collect excess moisture, special collectors are used and a hatch is inserted into the pipe for inspection.

- Wrong choice of steel. The chimney for the stove warms up to an average of 500 ° C, but for a short time the temperature can rise to 1000 ° C. Heating is uneven, so the material must be resistant to such changes. The steel should be heat-resistant, the pipe should be insulated 2 meters from the firebox to prevent overheating.

- Vertical offset of the brickwork next to it. This reduces the efficiency of the chimney, as flow turbulence and soot deposits will form in such a structure.

- Creation of an unreliable foundation for a brick chimney. Poor construction can lead to partial or complete destruction of the pipe.

A reliable and high-quality chimney can be made from different materials. Their choice depends on the features of the design and premises. The easiest way is to make a chimney from steel, cheaper - from brick. If you need to make a durable structure, choose ceramics.