To create heated floors that are placed in a concrete screed, it is recommended to carry out the reinforcement procedure using a mesh. Mesh for underfloor heating or cable-type systems is divided into several varieties and is created from a wide variety of materials. Before buying, it is useful to study the available types, the features of their installation and fastening.

Main purpose

Although the installation of a mesh under any warm floor is not considered necessary, experts recommend doing it. Due to it, it is possible to increase the strength and operation of the system, to prevent its deformation and the appearance of cracks. The mesh helps to distribute the load evenly across the entire substrate from furniture pieces and base coat. You can also reduce the cost of cement during the preparation of the mixture, reduce the thickness of the screed, which will not affect the strength properties of the device.

During installation, specialists fix heating elements and other parts to the base, reducing the need for additional fixings. In addition to the main advantages, the mesh increases the performance of the floor heating system. If installed, the heating cable and circulating heating medium pipes will not be in close contact with the base. As a result, the heat output of the floor is significantly increased. The reinforced version evens out the floor and makes it almost perfect.

Varieties of mesh

Before installing the system, you need to decide in advance which mesh to use for the warm water floor. It is available in several versions, each with its own characteristics. The width of the cells varies from 5 x 5 to 30 x 30.

Wire

Wire-type metal mesh with a diameter of 2.5 to 6 mm is presented in rolls up to 25 meters in size, which eliminates unnecessary joints. Its cells are square, they are as strong as possible, due to which the structure will not stretch during the entire reinforcement process. The surface part of the wire version is supplemented with notches that provide good adhesion to the concrete mix.

The cover is supplemented with a galvanized layer that protects the mesh from moisture and other components. Reinforcement with a metal base is available for pouring a dense layer of cement and helps to maintain shape. Heating elements can be attached to such a grid, for example, an electric cable or pipes from a water system. The main advantage of the wire mesh is its strength, the main disadvantage is corrosion.

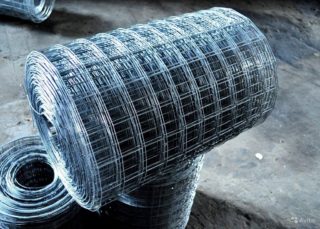

Welded

Underfloor heating on a welded mesh is installed in a shorter period of time. A welded element is required for a guide structure to which piping elements are added. The main importance is the size, in the selection process it is determined in advance whether it will be used as a reinforcement for a screed. In some cases, experts take into account the dimensions for the cells during design.

The optimal choice is a welded mesh with cells of 50x50 mm. It is the easiest way to install pipes for underfloor heating along it, since there are many fasteners.

Reinforcing

Reinforcing mesh is designed to prevent deformation and destruction of the concrete base. It can be metal, plastic, or fiberglass.It is necessary to use it to create floors with insulation. In the presence of a movable foundation, supplemented by expanded clay or crushed stone, such an element will be installed as a support.

It is also advisable to use it for floors exposed to moisture, pressure, vibration and temperature extremes. Such systems are installed in garages, utility blocks, industrial buildings, under a fireplace, in a bathroom or in a kitchen.

Masonry

Basalt fiber masonry mesh has more advantages compared to analogs of this type. This material does not change size when cooled and heated, and is resistant to corrosion and decay. Such a mesh is lightweight, therefore it does not create loads on the floors, its optimal thickness cannot affect the parameters of the screed. It is environmentally friendly and does not emit harmful vapors when heated, durable and capable of withstanding severe stress and damage. Also, the masonry mesh has a low thermal conductivity, due to the reinforcing layer inside the floor system, cold bridges are not formed.

Polymer

The polymer mesh is designed for installation of a lightweight structure, it has a long service life, does not deteriorate due to corrosion or moisture. It is sold in the form of rolls up to 50 meters long and up to 2 meters wide; its cells must be of different sizes. The floor construction made of polymers is not subject to shrinkage with the help of concrete, only slightly stretches during operation. Such products are distinguished by increased strength, no problems during installation and transportation, as well as low cost when compared with metal structures.

The mesh is considered an important part of the flooring system. It is needed for laying and fixing heating elements, including pipes or electrical cables. Due to the structural details in the form of cells, it can be laid on the floor without prior marking.

Feature of the reinforcement procedure

The reinforcement procedure improves the quality of the pavement screed, increases its density and extends its service life. Loads begin to be distributed evenly over the floor surface from standing furniture and while people walk on it.

Before reinforcement, it is necessary to study the instructions and follow its stages and rules. To strengthen the screed, plasticizers are added to the grouting mixture to evenly distribute the solution.

Fundamental rules:

- the mesh is made in the very thickness of the concrete layer, and not on the rough fields;

- meshes in the cells are made in such a way that they do not inhibit the pouring of concrete;

- do not allow dirt to enter the cells;

- to prevent corrosion, all elements are recessed in the screed so that they do not protrude beyond the surface.

To fix the contour for the floor or cable, clamps soaked in hot water are used. They become soft and fixed as comfortably as possible. They can be replaced with wire or tape as needed.

Installation technology

Before installation, you need to level the base of the floor and eliminate possible defects, for example, cracks, chips and an old screed, they are covered over and cleaned with a special mixture. At the second stage, a layer of waterproofing is laid using a polyethylene film, a heater is placed on it in two layers. A damper strip must be glued around the perimeter of the room to compensate for the expansion after the solution has dried. Further, on top of the layer of insulation during installation, beacons are placed to level the screed, then a reinforcing mesh is laid with an overlap of 10-15 cm.

Fastening the pipe to the mesh

To fix the pipe on the mesh, standard clamps for cars are purchased and tightened during the installation process. There are other options for fastening with reinforcing wire or fastening tapes, but clamps are considered the most reliable.