Despite the autonomous heat supply, stove heating can help out the owners during the off-season. Using a stone stove, you can maintain a comfortable temperature, normalize the indoor climate or cook food. Independent laying of the stove is carried out according to several schemes, it requires strict adherence to the sequence of work.

The main types of stoves

The brick type oven is designed for heating the house, cooking food, or for everything at once. To select the appropriate option, you must familiarize yourself with each variety.

Heating device

It is possible to fold a heating stove with a fireplace or a single firebox in order to heat the rooms. Structures are built into the interior partitions or perform the zoning function if installed in the center of the hall.

The heating type of stoves is used as a main or additional source of heat. Structures are most often operated in the off-season or during the cold season. They are installed in the presence of a kitchen with a modern electric or gas stove, as well as in summer cottages.

Cooking modifications

If you have the knowledge and skills to work, it is easy to fold the cooking oven, which is designed for quick cooking or baking. The hob and the back of cast iron heats up quickly and accumulates heat for a long time, which allows the structure to be used for heating.

The peculiarity of the stove is its compact size, which is suitable for a summer residence, a small kitchen in a private house. The device is also in operation at the moment when the electricity or gas supply is turned off.

Heating and cooking facilities

The advantage of this option is high-quality heating of several rooms, the ability to cook, boil water. Oven versions are also used for baking, drying fruits, vegetables and herbs.

The laying of a heating and cooking stove in the case of do-it-yourself work provides for its installation into the wall. The structure can be used as an independent load-bearing element - the tiles and the firebox are directed to the kitchen, and the rear part - to the living area. For an aesthetic appearance and decor of the room, the heating and cooking stove is equipped with a fireplace.

Brick kiln construction

By design, there are several types of structures:

- Dutch. The channel Dutch woman is compact and easy to self-erect. Due to its low efficiency (40%), it is installed in a garage, in a summer cottage, in a workshop and operated in a smoldering or slow burning mode.

- Swedish. The chamber-channel Swede has an efficiency of about 60%, is compact and practical. The product requires careful selection of building materials.

- Russians. With an efficiency of 75%, they are the most difficult to work with. Only specialists should fold these structures.

A Russian stove is often equipped with a bathhouse, a residential building or a two-story summer cottage.

Universal cooking and heating units are the most popular option in homes and summer cottages. They consist of an array with a firebox and an air duct, a chimney and a foundation.

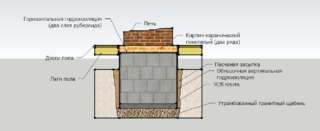

Foundation

It is necessary to fold the base for the stove separately from the general house foundation:

- due to the large weight of the structure, the soil sags more than under the walls of the building;

- the furnace unit has unstable linear dimensions due to heating;

- between the heating structure and the load-bearing walls there must be an indentation that protects against fire;

- a separate base is easier to rebuild, modify and repair.

For the manufacture of the foundation, rubble or brick is used, the binder is lime or cement.

It is impossible to fasten parts of the foundation with clay - it crumbles in a humid environment and cracks when heated.

Solid wood stove

- bandage the seams;

- soak red bricks for 10-15 minutes in water so that they do not take water from the solution;

- control the horizontal and diagonal lines of the row;

- fill the joints with mortar without excess;

- wipe the inside of the chimney with a wash brush.

The construction of the kiln massif is carried out with a preliminary dry set. Fitting allows you to mark the structure with respect to other elements of the room.

Trumpet

The chimneys have a vertical arrangement and are distinguished by clear parameters of height and section. Depending on the location, the chimney is:

- mounted - continues the structure in a straight position, is located above the smoke flow and the body;

- indigenous - for the pipe you need a separate foundation, bring it to the stove using a sleeve in the corners;

- wall - the channel is located in the main wall of the house.

In the case of a protrusion of the pipes above the roof, they create an otter - an expansion structure, preventing the access of condensate. In the area of the attic, the chimney must be plastered and covered with whitewash - this makes it easier to find areas with leaks. A metal deflector (cap with legs) blocks the access of rain and snow to the channel and acts as a spark arrestor.

It is best to equip a country house with a small stove with a mounted smoke outlet.

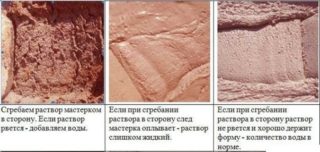

Specificity of using the solution

Before you put the stove on your own, you need to decide on the type of solution. In the construction of heating products, the following are used:

- Lime or cement paste - the viscosity of the composition depends on the specifics of the soil. For soil with a low level of moisture, a lime or lime-cement mixture is suitable. On wet soils, cement is used.

- Clay-sand mortar - for the body and smoke circuits.

- Fireclay sand mixed with refractory clay - for lining. The seam thickness should be kept to a minimum.

- Ready mixes - stones are laid on fireclay or clay-sand compositions.

- Lime or cement-lime mortar - for bundling the components of the stove in the attic.

- Cement paste - for the outer surface of the pipe.

When making a fireclay mixture yourself, take into account the fat content of the clay and select proportions from 1: 0 to 1: 3.

Features of self-finishing

It is not difficult to fold the oven with your own hands for a beginner, subject to the work algorithm. The main questions arise when finishing. The easiest option is to plaster and whitewash the structure well. If the brick is good, grout and jointing are sufficient.

Sloppy stove walls can be masked. Before finishing, the surface must be mopped, rubbed with brick and allowed to dry. After plastering with a clay-sand mixture with asbestos chips, they proceed to finishing. Heating and heating and cooking facilities are tiled.

Possible difficulties

It is not easy to start laying the stove without experience and practice. In some cases, it is necessary to change the location of the floor beams, disassemble the structure, demolish the foundation. To avoid mistakes, you must:

- Make a test laying on a brick without mortar. This makes it easier to understand the arrangement of the elements.

- Use wooden battens 5-7 mm thick to equalize the thickness of the inter-brick joint.

- Calibrate the thickness if laying under the jointing.

- Fit the bricks to size, number them with a marker and put them in a separate pile.

- Apply the mortar in a layer of 10 to 12 mm.

- Tap the brick laid on top with a rubber mallet until it stops in the rail.

- Remove excess mixture.

- Remove the planks after installing 3-4 rows, fill the seams with mortar and immediately embroider.

The evenness of the structure horizontally and vertically is checked by the level.

Laying a simple oven version

Self-laying of the simplest type of stove provides for the manufacture of a base and an array.

Building the foundation

A practical concrete monolith reinforced with a metal corner along the ribs is easy to construct. When finished, the foundation should protrude 5-7 cm from the oven. The depth of occurrence is no more than 75 cm, for a one-story house 50 cm is allowed, for a two-story house - 1 m. The base is not brought up to the floor covering by 14 cm, it is covered with tar paper or roofing felt for waterproofing.

The reinforced structure gains strength for 1-3 weeks - only after that a moisture-proof coating is organized.

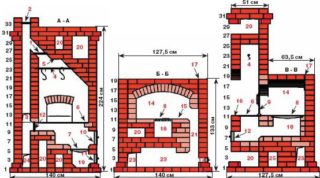

Ordinal masonry method

To fold the stove with your own hands, step-by-step instructions for novice craftsmen should not be complicated.

Sequential installation method:

- Marking of the future product on a waterproofing coating.

- Layout in a continuous first row with a check of evenness. Blowing chamber formation.

- Installation of the blower door. Steel wire is threaded into the ears and run into the seams. To eliminate the displacement, the sash is temporarily held in bricks.

- Installation of calibration strips and laying of the second or third row.

- Formation of channels for removing soot in the fourth row. You will need a separate flap for each hole.

- In the fifth row, the simplest scheme involves the installation of a grate. It is fixed in special grooves in the lower row. The door through which the structure will be heated is temporarily fixed with bricks or a wooden plank.

- From the sixth row, they switch to refractory bricks.

- Gas outlets are made from the seventh row and vertical walls are laid with fireclay bricks. The material is placed on the edge.

- Knocking out ¼ of a brick under the furnace flap in the eighth row.

- Laying wire under the cast iron part in the 9th row.

- In the 11th row, a furnace plate with a gasket made of basalt cardboard or asbestos cord is placed in the chamber opening. The end part of the hob is formed with a metal corner.

- 12 to 16 rows make a camera.

- Making a support for bricks of the 17th row by laying steel strips on the side walls.

- From 18 to 19 rows, continuous masonry is performed, two heat exchangers are installed vertically.

- Arrangement of a horizontal channel for the removal of soot and the formation of an oven in the 20th row.

- Overlapping doors in the 22nd row.

- Creating a horizontal flue overlap in the 23rd row. Installation of steel strips over the oven.

- Installation of a clearing flap and overlapping a niche in rows 25-28.

- Fastening the valves of the vertical gas duct (first the frames, then the partitions) in the 30th row.

- Layout of the transitional section of the chimney in 31-35 rows.

- The construction of the fluff from the 36th to the 38th row.

The chimney riser is laid out from 1 to 26 rows, the central flap is placed in the 27th row, and in the 31st section of the masonry there should be less to output the pipe through the roof.

In order to fold the stove in a high-quality manner in the country or in a private house, it is necessary to decide on the type of construction. Work begins after the arrangement of an individual foundation and the selection of a solution for each element of the structure.

https: //