Stove heating has not lost its relevance, since not all houses can be equipped with a boiler. In addition, gas and electricity are constantly getting more expensive. Stoves are installed in private cottages, summer cottages and baths. A variant with good heat transfer due to the free movement of the hot gas is the bell-type furnace. Due to the simplicity of the design, even a non-professional can assemble it with their own hands.

Design and principle of operation

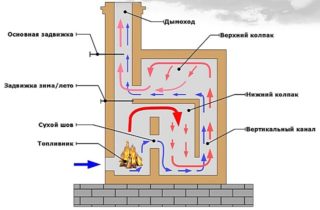

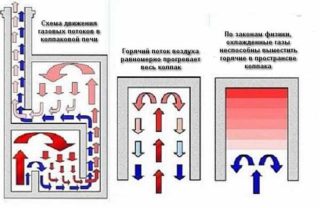

The stove with a hood was developed by engineer Igor Kuznetsov in the early 60s of the last century. Subsequently, the Russian metallurgist Leonid Kotlyar improved the design so that it retains heat up to 19 hours. The peculiarity of "blacksmithing" is that the heated air does not leave the pipe, but is collected under the hood. It gradually cools down and is displaced by rising hot streams. The advantageous difference between a bell-type stove used for heating a house and a duct stove, where hot air, under the influence of draft, freely goes out into the street, lies in saving heat.

A two-meter-high structure with a base of 1m * 1m can reach a heat output of 3.5–4.5 kW. Such a bell-type stove is enough to heat a house of 50 square meters in a temperate climatic zone, if you heat it twice a day.

The inventor has improved the design by adding another hood. In Kuznetsov's two-bell heating furnace, the first covering element is connected to the furnace compartment and separates the cold and heated streams. The second bell is located in the upper part of the stove, trapping hot air, which, before entering the chimney, gives off heat to the bricks for a long time.

A two-bell oven is more economical in fuel consumption and is usually equipped with a hob. This allows you to prepare delicious meals without consuming electricity or gas. The design of the stove already includes an extractor hood - there is no need to install an additional ventilation system.

In a classic stove, the heat exchanger is located at the bottom, which makes heating better. Moreover, this arrangement does not lead to the formation of a large amount of soot.

Advantages and disadvantages

Kuznetsov's designs have many advantages. One of them is the increased efficiency - 93 percent. For comparison - in Russian stoves it is about 80. At the same time, “blacksmiths” have uniform heat transfer, less temperature fluctuations.

Other design advantages:

- There is no soot left, and therefore the stove and the flue duct may not be cleaned for several years, which greatly simplifies maintenance.

- The device can be erected anywhere - in the corner zone, in the middle of the room, near the wall. Often, a two-bell oven heats several floors of a house on one tab.

- The stove chimney can be shortened to save bricks.

- "Kuznetsovka" is easily combined with a stove, fireplace, stove bench, differing in a variety of modifications.

- It is easy to connect a water circuit to the stove and pipe heated water for bathing or heating.

- Thanks to the increased level of pyrolysis, fuel is saved, which can be anything.

- The masonry will last longer, there is less risk of cracks.

- With the shutter open for a short time, it is almost impossible to cool the stove, because the cap is always filled with warm air, and the cold one is pressed downward.

There are few shortcomings of "blacksmiths", most of them are associated with construction: stove-makers who are ready to carry out such a project inexpensively are not easy to find.In addition, the units are quite large in size, but they are slightly inferior to Russian stoves.

Erection of a bell furnace

Tools and materials

From professional tools when building a stove, you need:

- hammer-pick and trowel;

- mallet;

- painting cord of considerable length;

- building level, rule and plumb line;

- roulette;

- angle grinder;

- jointing for seams.

For the stove itself, you need to get solid and fireclay bricks, grate, steel plates. Safety will be ensured by gloves and goggles to protect against flying dust when cutting brick blocks. To replace the solution, you need a drill mixer, a special container.

It is easy to prepare a solution for styling yourself according to a time-tested recipe, or buy a modern version in construction products. Self-masonry composition is made on the basis of clay, sand and water, sometimes manure is added for plasticity. The proportions depend on the quality of the components. The resulting mortar should be soft, viscous and not crack when laid.

Preparation and construction

For self-construction, you need to find high-quality drawings and instructions with ordering from experienced stove-makers or on the Internet. After that, you can start building the stove.

First of all, the foundation is laid:

- Dig a hole 100x150 cm in size and 0.8 m deep. In general, its dimensions should be 10 cm larger around the perimeter than the oven itself.

- Pour 20 cm of sand at the bottom.

- When the sand cushion settles, set up the formwork and reinforce the bottom with mesh.

- Pour the cement mortar 20 cm above the floor level.

The foundation needs to stand for about a month. Only after that you can start laying. Before erection, it is necessary to cover the base with a layer of reflective foil slightly wider than the foundation in order to further reduce heat loss. If the house is made of wood, an asbestos sheet is laid before the foil covering. When everything is ready, the edges of the foil can be cut off.

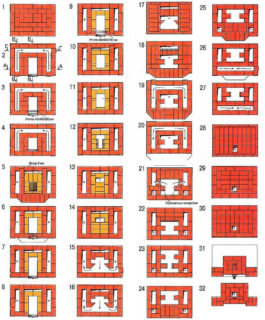

A classic bell-type stove is erected in 30 rows, although their number can be reduced or increased, the main thing is to follow the instructions. To build it, you need to act according to the following plan:

- The first row of bricks is laid out evenly, the side walls move from right to left using the spoon method. As a result, the back and front sides will be laid in four bricks, the right in two, and the left in three.

- On the second row, a blower door and a window for cleaning a single-bell stove are mounted. It can be made anywhere, but with one condition - its location must be below the firebox compartment. The next row fits in a similar order.

- Further, the connector for disposal of incineration waste is reduced. It should be approximately half a brick in width. In the farthest row from the firebox, a partition is installed leading to the upper compartment.

- The rows are laid according to the scheme, but the edges of the discharge hole must be overlaid with fireclay bricks, and a grate should be placed on top. The next row lays down in a similar order.

- In the seventh row, the chimney is brought out into the half-brick from the combustion pipe so that it goes into the adjacent air compartment. The next level is put on a similar principle.

- Now the combustion compartment is covered with solid bricks, and lined with fireclay from the inside. The tenth and eleventh rows are placed unchanged.

- On the twelfth, a lathing of refractory bricks is laid out. The row itself is put in half a brick. The masonry of the thirteenth row is carried out in a similar way.

- On the fourteenth row, the movement of smoke is blocked by means of a metal plate, the crossbar of the smoke collector is assembled from bricks. As a result, a single channel should be formed, which remains during laying in the fourth row.

The first building block is complete. To form the second, final level, the laying is carried out in the same way as before. The intake plate must be fixed with mortar on one side. When laying the nineteenth row, put a brick block for the base of the column under the roof of the structure in the middle of the smoke collector. A space one brick wide is left behind the tiles. Up to the twenty-first row, blocks are laid out according to this scheme.

Then it is necessary to close the channel leading to the pipe, since the smoke will come from the space left below. In the 22nd row, the walls of the wind hole are strengthened with steel plates. You can purchase a ready-made rim with doors, then it will be easier to equip the oven. At the same time, the hood is laid out in a quarter of a brick.

Laying according to this scheme is carried out up to 24 rows, then a step is created and a steam collector is connected to the chimney, the channel is closed. In the 27th row, a fence plate is placed, and in the 28th row, the device is covered with a brick roof. The masonry is completed by attaching a pipe with a section of one brick.

Do-it-yourself Kuznetsov's two-bell furnace is created in a similar scheme.

Upon completion of the construction, at least a day must pass for the solution to completely solidify. After that, a check is carried out by igniting a small amount of fuel. If it is found that the structure is leaking in some place, they troubleshoot.

Even a beginner can lay out Kuznetsov's stove according to ready-made orders. But you need to strictly adhere to the instructions so that the design is durable and safe.

If you don't want to lay out a brick stove, you can buy a metal analogue. Its cost is from 33 thousand rubles. For industrial purposes, dome ovens are used, created according to a similar principle. Their cost starts at half a million rubles.

So very careful. I made myself a two-bell oven - excellent draft, good warming up. But in the caps "waste" remains for a very long time. Such a minus cost the life of my parrot. How this fate escaped me personally, just luck. So just in case - be careful. Check it out. Forewarned - forearmed.

It is enough by continuing the extraction downward by cutting the pipe into metal. ovens get the same effect. (Bell-type oven.)