The Ermak company has been on the market since 1997 and is one of the largest manufacturers of heating equipment. Ermak bath and standard stoves are distinguished by their reliability and ease of use, have compact dimensions and are able to successfully fit into the interior of any room. Buyers can choose the suitable model from several series depending on their needs. Before buying, it is worth examining the pros and cons of the brand's furnace equipment, their technical characteristics and the available model range.

Device and principle of operation

The manufacturer produces classic-type furnaces and updated models that differ from the traditional ones in functionality and principle of operation. Standard equipment works according to the scheme of simple flue channels, has a rounded body and attachments for additional elements on the back wall. For the furnaces from the new line, a complex two-flow gas duct scheme was developed, due to which the intensity of heating the stones and the overall efficiency of the device significantly increased. Stoves for stoves from Ermak are made of cast iron or stainless steel, stoves and smoke channels in them are made of stainless steel.

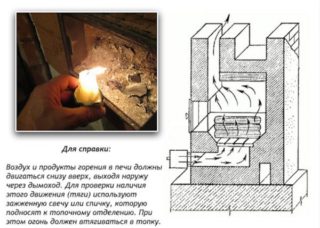

Firewood, gas or briquettes can be used as fuel for the stove from Ermak; recently, combined devices have become more and more popular. Their power ranges from 12 to 36 kW, depending on the design, configuration and functionality. The Ermak furnace or boiler works according to a simple principle: the fuel creates heat energy and heats the room, the products of its combustion are removed by means of gas outlets.

To expand the functionality of a bath or standard stove, it is supplemented with auxiliary elements, the list of which may include:

- a heat exchanger for heating water in an adjacent room;

- hinged tank for a steam room;

- mesh heater;

- convector screen for protection from infrared radiation;

- a steam generator that removes finely dispersed vapors;

- remote tank for heating water in the washing room.

The main element of every Ermak sauna stove is a firebox, at the base of which there is an ash-pan. With its help, you can change the intensity of fuel combustion, eliminate unburned fragments and ash.

Advantages and disadvantages of Ermak furnaces

The Ermak sauna stove is made of high quality cast iron and steel, which are rigorously selected at the stage of acceptance before production. Working components are made on equipment from foreign manufacturers. The design of budget and luxury stoves is constantly being improved, the company updates the existing model range and develops new modifications. The list of the main advantages of Ermak sauna and bath stoves includes their ability to quickly warm up the room, the ability to customize equipment according to needs. They also have a simple and stylish design, ease of installation and are sold at affordable prices.

In addition to the positive characteristics, the owners of the stoves also note the disadvantages of the equipment. Standard bath models are not suitable for saunas that require more careful selection of parts and elements. Some buyers are not satisfied with the too simple appearance of the stoves - there are no devices with a complex design in the manufacturer's lines. It should also be borne in mind that the ovens cool down too quickly after being turned off.For the rest of the parameters, the equipment of the standard and premium classes does not cause difficulties and is able to compete with analogues from Russian and foreign manufacturers.

Specifications

Stoves and fireplaces from the manufacturer Ermak are distinguished by good technical indicators. The devices are made of refractory materials and supplemented with elements of a thermally stable substance, capable of withstanding temperatures up to 2000 degrees and a humidity level in the room up to 30%. In the manufacture, innovative materials and advanced technologies are used. Each unit is distinguished by the high quality of welds and other parts, fully complies with international fire safety standards.

The design of the furnace is thought out to the smallest detail, the devices have a modular structure, which allows them to be supplemented with auxiliary parts. The stoves maintain the optimal atmosphere and temperature in the room, do a good job with their main functions of the heater. All units of the brand comply with European standards, they are given a manufacturer's warranty for up to five years. One of the main advantages of Yermak garden and home heating stoves is ease of installation: it is enough to install the device on a prepared surface and connect it to communications.

The process of heating the furnaces is fully automated; to connect the device, it is enough to turn the handle of the switch and set the desired temperature value. When installing the stove in the steam room, the units create the most comfortable conditions. The devices can be additionally lined with brickwork, equipped with external water tanks. The optimal length of the firebox for each stove allows you to install a firebox door with a pipe in an additional room.

To prevent possible injury, the stove can be equipped with a wooden frame. It should be located at a short distance from the device; when manufacturing it, you need to remember about fire-prevention measures.

The lineup

The model range from the Ermak company includes equipment of three categories: sauna stoves, water heaters and electric heaters. Units for a bath or a Russian sauna differ from each other in terms of performance and types of working modules. Stoves are presented in open and closed versions, according to the type of body, all devices are divided into casing-convectors and oven-mesh.

The first option is ideal for a Finnish sauna, as it is able to heat the air as quickly as possible in dry heating mode. The second one is chosen for a Russian bath, since such devices have a low level of convection and heats the room more slowly, while retaining heat longer. The list of brand sauna stoves includes modifications of the following types:

- 12 PS. The stoves are small in size and are suitable for small baths. The Ermak series 12 furnace has good heat transfer and can operate on various types of fuel with a maximum heating level.

- 16. Compact and small-sized devices designed for heating large premises. They are often used in baths with large areas, where it is necessary to evenly warm up the entire space.

- 20 standard. The furnaces are equipped with a double-flow gas outlet system and furnaces up to 55 mm deep. Their weight and volume of water tanks can vary significantly, so choosing the desired modification is worth taking into account the scale of the room.

- 30. Such devices are of great weight, volume and power. Thanks to the simple design, it is easy to install a heater or heat exchanger. In the presence of such a stove, it is worth creating an open steam room in the bath due to the high level of humidity and chimneys with a size of at least 60-65 mm.

Small-sized options are better for those who want to economize on fuel and are looking for a compact-sized oven that does not cause problems in maintenance and during installation. Combination models are ideal for those who do not plan to use firewood as fuel. Electric heaters are the best choice for buyers looking for appliances that can warm up a room as quickly and quietly as possible.

Features of operation

The combustion process must be monitored and ensured that the stove does not heat up until it becomes red. To reduce the amount of soot during every third or fourth furnace, dry aspen or foliage of other species is placed in the hot stove. Twice a year it is necessary to carry out a preventive examination of the stones, remove them and clean the inner surfaces of the stove with a soft cloth soaked in detergent solution. This will help to avoid the accumulation of dust and steam products.

Water is poured in before starting the kindling of a standard or suspension device. Filling the heat exchanger with water after the start of fuel combustion can damage the internal communications. Caring for the stove and its correct operation significantly extend the service life of the unit and help to avoid fire hazardous situations.