A non-volatile gas boiler is used to obtain thermal energy by burning gas for heating objects (rooms). Propane-butane or methane is used as a gaseous fuel during the operation of the unit. Boilers are installed only for heating or additionally heat water in the water supply system. The equipment is available for floor-standing and wall-mounted types.

The principle of operation of a non-volatile gas boiler

When fuel is supplied, the piezo ignition is turned on, the igniter ignites from the spark, which will burn constantly. If the ignition device does not work, gas must not be supplied, as an explosion may occur. The pilot burner ignites from the pilot and heats the water to the desired temperature in the heat exchanger. Automation turns off the gas after reaching the set result. The temperature sensor regulates the supply of a new portion of fuel when the temperature drops, and the main burner ignites again.

If there is poor draft in the chimney or the air flow is improperly organized, some of the carbon monoxide remains in the room. It is dangerous and causes toxic carbon monoxide poisoning. A non-volatile gas boiler requires a chimney device with a ratio of the volume of incoming air to the amount of exhaust combustion products of 10: 1. Non-volatile units operate without electricity due to the presence of two burners in the structure.

Types of boilers

Gas units are hung on a load-bearing wall, located on a frame. Massive models are installed on the floor or require an additional base device. The equipment is connected to the heating line, water supply and the hot floor circuit.

Single-circuit and double-circuit

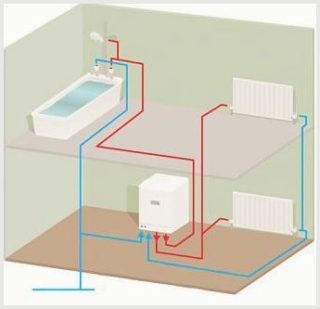

An energy-independent gas boiler for heating a private house works only for heating or additionally heats water in a built-in tank. It depends on how many circuits it serves. When a house is heated, a hot coolant enters the pipeline. He goes through all the registers in the house and returns to the boiler. This is how a single-circuit system works, it is used for non-residential buildings, summer cottages, workshops.

In double-circuit units, a heat exchanger of a different structure is built in. Another pipe with a liquid for a water supply is inserted into the pipe through which the coolant passes. The streams move in one direction. From the combustible gas, energy is transferred first to the filler of the heating system, and it heats the water for domestic purposes.

Flow-through or built-in heat exchangers are:

- bithermic coaxial;

- separate lamellar.

Floor-standing models of boilers can have 2 heat exchangers, where liquid for heating and water for hot water supply are heated in different containers. Such units take up more space, but less scale is formed in them. The circuits operate separately and are disabled independently of each other. They are used in private one-story and two-story buildings.

Floor and wall

Floor-standing units are mounted on the floor or platform. Structural elements for strapping are purchased separately.

Steel fire tube boilers are distinguished by:

- increased power indicators;

- high efficiency.

The heat exchanger is cylindrical with welded seams. The structure consists of metal pipes and an air-gas mixture combustion chamber. The combustible mass is prepared and supplied by a blowing burner.

Cast iron units have a sectional type iron-carbon alloy heat exchanger. It houses blast or tubular burners. Cast iron boilers are distinguished by their heavy weight and long service life. Due to the fragility of the material, special requirements are imposed on the temperature regime.

Wall-mounted models are characterized by reduced power, compactness, mounted on a vertical fence or a stationary frame.

The advantages of suspended boilers:

- saving space;

- sale of strapping elements simultaneously with the unit.

The wall-mounted equipment is a mini-boiler room controlled by a remote control. The boilers have a copper or steel heat exchanger in which a tubular burner is mounted.

Advantages and disadvantages

Non-volatile gas units are efficient and fuel efficient. The boilers provide for automatic protection when the gas supply is cut off, the liquid pressure in the system drops, and the draft is lost.

Benefits of non-volatile equipment

- high power;

- independence from the electrical network;

- durability and reliability in work;

- ease of use;

- the possibility of quick repair;

- the likelihood of using a chimney from a previously dismantled solid fuel boiler or stove.

Restrictions for the installation of gas equipment relate to the choice of a separate room. For a two-circuit system, additional space is required for the installation of the security system, pump, heating tank. The cost of the installation increases due to the weight and dimensions, the assembly of the control automation into the structure, and the leveling of the base. A permit is required from the gas service.

Selecting a non-volatile boiler

The choice depends on the purpose of the object and the financial capabilities of the buyer. There are other parameters that you pay attention to before purchasing the unit.

Technical characteristics are taken into account:

- Power. If the indicator exceeds the heating requirement of the room, excess fuel is consumed. For double-circuit boilers, 25% is added to the area of the house for the needs of hot water supply.

- The number of contours. Depends on the purpose of the building. In medium-sized residential buildings, double-circuit units are installed, and single-circuit units are suitable for auxiliary buildings. If the cottage is large, a water heater is additionally mounted to the boiler.

- Heat exchanger material. Steel models save money, but cast iron is chosen for long-term operation.

- Gas consumption. The models have different combustion rates and different efficiency.

- Temperature limit of operation. Gas units heat water up to +80 - 90 ° С.

- Coordination and management system. Automation ensures independent operation of the unit without human intervention.

The design and dimensions of the unit are selected depending on the user's preferences. There are a large number of standard sizes, but the appearance does not affect the quality of functioning.

Rating

Most of the offered boilers are manufactured abroad. The leading place is given to Germany, Italy, Slovakia, Belgium, South Korea.

Popular quality models:

- Protherm Cheetah. Wall-mounted model of a two-circuit unit with a power of 23.3 kW. The efficiency is at the level of 90.3%, heats the house up to 200 m2. The compact unit weighs 31 kg.

- Ferroli Domina N F24. Non-volatile model with a power of 23.5 kW. Double-circuit equipment with a closed chamber. Heats the area up to 180 m2, efficiency - 93%.

- Baxi Slim 1.300 iN. Floor-standing construction with cast iron heat exchanger. It is possible to connect an external boiler and a floor heating system.A built-in outdoor temperature meter is provided, which facilitates the operation of the automation. Heats up to 365 m2.

- Ariston GENUS Premium EVO 24 FF. Wall-mounted double-circuit model with display and front panel controls. Gas consumption is not more than 2.5 m3 per day. Stainless steel heat exchanger, it is possible to connect a pump and a forced fan.

- Navien GA 35 KN. The device is of low weight and dimensions, equipped with connecting pipes on both sides. Convenient control, instructions in Russian. The unit works quietly, the internal elements function reliably and for a long time.

Models of well-known manufacturers take into account the conditions of the Russian climate and work efficiently.

Design features

In forced-action units, air is taken from the street or from an adjacent room (less often). The streams are moved by a fan along coaxial or separate small diameter air ducts. There is a possibility of organizing the removal of combustion products in a horizontal plane through the wall. Forced feed equipment is installed in any suitable room.

Features of installation and operation

Non-volatile gas-fired heating equipment is installed in the system so that the coolant circulates naturally without using a pump. For this, the following conditions are met:

- the calculated slope of the line with the coolant is maintained;

- pipes of larger diameter are used to reduce the resistance in the path of the liquid;

- an expansion tank is built into the system, where excess hot water is located.

When installing, adhere to the rules for installing gas boilers. The norms also apply to the ventilation and exhaust system. Installation of equipment is allowed to persons who have access to such work and have been accredited.