Any bath must have a boiler or stove. They are used to heat water and create a high temperature in the steam room. There are many types of bath boilers, the differences of which must be understood in order to make the right choice. You can also make your own boiler for the bath.

The difference between a boiler and a furnace

Fuel burns out in the firebox of a sauna stove, resulting in the formation of ash, volatiles and heat energy. The body of the structure heats objects and contact surfaces. They, in turn, heat the room due to convection. The boiler has a different operating principle. The chamber also burns fuel and generates energy, but its distribution occurs due to air circulation.

The advantages of the boiler include:

- Absence of "dead zones". The process becomes predictable and manageable.

- Single and multi-circuit boilers can be installed. The first one heats the bath itself, and the additional circuits perform other tasks: heating the water, supporting the work of the warm floor.

- There are devices with automated control. This greatly facilitates operation.

- A more thought-out design and high functionality make the boilers more attractive for installation in a bath. They also have a higher efficiency and are more economical in terms of the fuel used.

- It is easier to install a boiler yourself than a full-fledged brick oven.

- Can heat large rooms.

For a full-fledged bath with several compartments, it is better to choose a boiler for heating.

Varieties of boilers

A bath boiler is a device that performs 3 main functions: bringing stones to a red-hot state, heating water and heating the room.

Boilers can be divided into several groups according to the type of fuel used:

- Solid fuel. Coal, firewood, peat are used as raw materials. Such devices retain heat for a long time and do not require connection to an additional power source. Operation is quite expensive, so it is better to put them only for heating water in the washroom. It cannot work in automatic mode, it emits dust from coal during operation. Requires regular cleaning.

- Electrical. They operate from the mains and represent a conventional water boiler. The installation of such equipment is inexpensive, but it cannot be called economical because of the consumption of electricity. They are rarely used due to the need for a three-phase network with increased power. The positive aspects of the electric boiler include environmental friendliness, cleanliness in the room and the ability to work in automatic mode. Suitable for installation in a small bath as an additional source of hot water.

- Gas. Gas acts as fuel. One of the most efficient and profitable types of heating devices. Differs in compact design, ease of use and versatility. The user does not need to constantly purchase fuel. Does not give off odor or burning. Explosive, so it is forbidden to assemble such devices with your own hands. There are single-circuit for small baths, double-circuit for heating water and heating the dressing room and three-circuit for heating the pool (if available).

- Products powered by liquid fuels. It can be kerosene, diesel, diesel fuel. The advantages include automation of work, safe and fast operation, and the release of a small amount of burning.No installation permission required. The main disadvantages are a strong smell when burning raw materials, the fire hazard of diesel fuel, the need to strictly adhere to the installation requirements for all parts of the equipment.

Also, the classification is made according to the material from which the boiler is made. Cast iron models are not used, as they are not allowed to be installed in the steam room. The most popular materials for a steam room boiler are:

- iron;

- brick;

- brick lined iron.

Thanks to modern technology, the size of the boilers has been significantly reduced. A miniature heater can be placed even in a small bath.

Criterias of choice

A large selection of boilers for a bath is on sale. It is difficult for a beginner to understand the features and differences of each species. The following criteria must be used:

- Heating area. The larger it is, the more powerful the boiler will be required. For baths, the thermal power is 1.27. This means that for heating a room with an area of 30 sq.m. and with a ceiling height of up to 2.3 m, 3.8 kW of energy will be required every hour. In the absence of high-quality thermal insulation, this indicator increases, since there will be heat losses. If there is a water heater, the value will also increase.

- The choice of the optimal type of fuel. In the case of a wood-burning bath, it is necessary to foresee in advance the place where the wood will be stored. The cost of raw materials must also be taken into account.

- Material. Most often, boilers are made from different types of steel. The water heating tank is selected from stainless steel for long-term operation. Cast iron boilers are not used in the bath.

- Product design. Here the presence of a remote firebox, the possibility of adjusting the draft is considered.

- Dimensions.

- Possibility of rational stone stacking. If a wood-fired sauna boiler is installed, it is important to provide a place for placing the masonry. Steam from the stones enters the steam room when sprayed with water. When creating such a place, it is important to consider several factors. The larger the volume of the masonry, the more intensively the boiler works and the longer it retains heat. At the same time, more time is spent on heating. The second factor is the location of the basket in the boiler piping. It is necessary that the stones are heated in full and receive maximum heat.

The market offers models for each specific case. It is also possible to make custom-made sauna boilers according to the requirements stated by the buyer.

Installation rules

After selecting and purchasing the optimal model, you can proceed to installing the heating device in the room. This can be done with the help of professionals or on your own. When working, the following rules must be observed:

- If the weight of the unit exceeds 400 kg, a foundation base must be made. It will also be required if the floor structure contains logs with a cross section of less than 150 × 50 mm and boards up to 40 mm thick. If the foundation is not built, the floor will not support the equipment.

- It is necessary to make a fire-resistant surface on which the boiler will be installed. The material can be a metal sheet laid on a layer of mineral wool, or ceramic tiles.

- Installation will require the use of a welding machine. Such work must be carried out in compliance with safety precautions. The foreman must have sufficient qualifications to do welding. Personal protective equipment is also needed. The welding machine is connected to a separate power line, as it has a lot of power.

- Compliance with the requirements of GOST and SNiP for the distance from the boiler to the surfaces of the floor, ceiling and walls.

- All smoke-removing elements must be packed in heat-insulating sleeves. You need to be especially careful about working out the junction points.

The boiler can be installed by two people with sufficient qualifications. It is difficult to install the device alone, since it is heavy.

DIY creation

If you have the skills and abilities, you can make a boiler yourself.

First you need to select the type of fuel. It is not recommended to independently manufacture electrical and gas products, as the risk of an emergency increases. In addition, the gas boiler must be checked by the appropriate service for safety and correct operation. All these actions require large financial investments, so it is better to buy a ready-made device or assemble a solid fuel installation.

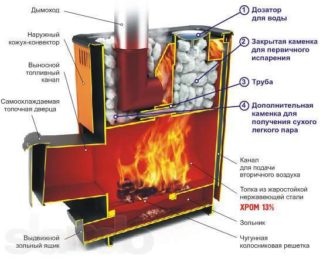

The sauna boiler consists of the following parts:

- Firebox. In this part, the combustion process takes place.

- Chimney. Serves to remove combustion products from the room.

- Ash pan. It is a place of ash accumulation and serves as a blower.

- Kamenka. This is the main part, consisting of a metal box with stones. In contact with water, stones give off steam to the room.

- Hot water tank.

The iron boiler has a simple design. Before starting work, it is important to study the drawings and purchase the necessary equipment.

As a basis, you can take thick-walled metal pipes with a diameter of 50 cm and a length of 70-100 cm. The resulting device will be able to heat an area of 9 sq. M.

During the creation of a boiler for a bath with his own hands, the master will need the following tools:

- welding machine;

- grinder and circles for metal.

After preparing the materials, you can go to work.

Welding structure

Algorithm for welding a boiler into a bath with your own hands:

- The body of the device consists of a pipe. In it, you need to make three supports parallel to the ground at different levels. To do this, you need to take pieces of reinforcement 3 cm long and 1.4 cm in diameter. The first level is for installing the device, the second is for the blower door, the third is at a distance of 20 cm from the top.

- For the bottom, a circle with a pipe diameter cut from steel is suitable. Thickness 5 mm minimum. You cannot take less, otherwise the bottom will not withstand the load.

- Creation of a grate for oxygen supply. It is made from a metal circle with the maximum permissible thickness with slots.

- The cover, which acts as a support for the stones, is also cut from 5 mm thick steel sheet. In the middle, you need to make a hole for the chimney pipe.

- Creates a hole at the bottom of the pipe for the box, which is closed by a door. The depth of the box is determined by the thickness of the walls.

- Creation of a box. Inside, there should be a partition for the combustion and ash chambers. The level of the partition is the same as that of the grate.

Then you can proceed to the final assembly of the unit.

Final assembly of the structure

The process consists of several stages:

- Welding the box. In the case of indoor work, it must go to the combustion room or to the street.

- Installation of the chimney in the hole on the cover in a horizontal position.

- Construction of the foundation. An iron slab or concrete screed 10 cm thick is suitable for it. The screed must be poured onto a 15 cm crushed stone pillow.

- Installation of the structure on the base. Stacking stones on the lid.

All parts need to be welded together. Next, a brick heat shield is made. To do this, the boiler can be lined entirely with bricks or a small wall can be made. Holes must be made in the lower part for air circulation.

After completing the work, you need to inspect the bath boiler and test the system.