A waste oil boiler with a water circuit is a floor heating equipment operating on an unusual fuel, in the form of a working off. The device is more economical than gas counterparts. The design will be the best choice for providing heat to private houses, where it is expensive to use electricity for heating, and the gas main is not provided or is still under development. The boiler will solve the problem of heating large areas from 600 meters, save money for people who have free access to large volumes of waste oil.

Operating principle

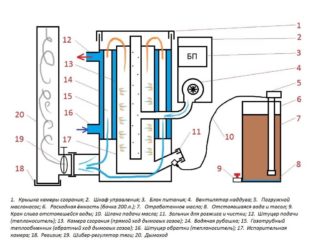

Waste oil boilers with a water circuit have some differences with diesel / gas designs. Before burning, the fuel must be strongly heated in a specialized chamber, which is most often located on the outside of the burner.

Principle of operation:

- By means of a pump from the fuel storage tank, the waste is transported to the preheating tank. A special float regulates the supplied volume.

- With the help of a heating element (TEN), the oil is brought to 80-110 ° C.

- After reaching the operating temperature, the fuel is transported through the injector into the combustion chamber, where it is mixed with air by means of turbocharging.

- The heat exchanger heats up and transfers energy to the coolant circulating in the circuit.

Vertical drip models function in a slightly different way:

- from an external reservoir, oil is poured onto a hot bowl located in the combustion chamber;

- hitting a hot surface, the fuel evaporates;

- due to the injection of air, the resulting mixture is completely burned out.

In this case, the walls of the chamber are a water jacket, which, when heated, divides the heat with the coolant.

The oil / air mixture burns at a temperature specified by the manufacturer. Most often, the parameters vary within 600 ° C. It is important to ensure that there are no deviations from the norm, otherwise this will lead to rapid contamination of the combustion chamber and other equipment parts, the fuel burnout process will be incomplete and toxic substances will begin to form inside the boiler. In order to increase safety and increase the service life of the structure, it is advisable to entrust commissioning work to professional craftsmen with the appropriate qualifications.

To generate 11 kW of heat, 1 liter is needed. working off. With natural losses, on average, at a power of 30 kW, 3 liters of fuel per hour will be consumed. The parameters specified in the instructions by the manufacturer are mainly designed for uninterrupted operation of the equipment.

Advantages and disadvantages

- Autonomy. The oil heating system does not require gas supply.

- Reliability. A simple, understandable design, with correct and accurate operation, rarely requires repair. The main thing is to carry out maintenance in a timely manner and change worn parts.

- Benefit, savings. Waste oil is an inexpensive and efficient fuel and is less expensive than gas and electricity.

- Wide range of applications: office buildings, residential buildings, manufacturing / industrial areas, etc.

- Environmental friendliness. During operation, the fuel burns out completely, which guarantees the absence of emissions of harmful substances into the atmosphere.

- Fast heating.The operating temperature is reached quickly, heat release begins from the first minutes of operation.

In addition to the advantages, the boiler for working out has minor disadvantages:

- The need for regular maintenance. Since used oil is recyclable, it contains a variety of impurities that settle on the surfaces of the structure. To reduce frequent breakdowns, the walls of the combustion chamber require constant cleaning of contaminants.

- Chimney installation. Oil boilers require the installation of additional elements.

Before choosing this type of equipment, it is necessary to assess the availability of fuel. Development is mainly carried out at service stations, some enterprises.

Double-circuit boilers

Oil double-circuit heating allows, in addition to heat, to provide residential / non-residential premises with hot water supply. The flat surface of the tank filled with water is warmed up and the pressure in the line is regulated with the help of a pump. The temperature of the supplied liquid practically does not change, therefore dilution with cold water is necessary.

It is recommended to use tanks with a volume of no more than 140 liters in heating operating on mining. The boiler heats up in a short period of time, on average 2 hours depending on the size of the reservoir.

Diy waste oil boiler

For a boiler for working off with your own hands you will need:

- sheet material for the tank, lid;

- oil pump;

- heat-resistant sealant;

- chimney equipment pipe;

- steel adapters;

- fan;

- support metal adapters.

It is also important to prepare the tools in advance: a welding machine with electrodes, a grinder, a construction tape, a set of keys, a drill, a hammer. Oxygen / propane barrels can be used as a boiler, this will speed up and facilitate the procedure.

Stages of independent production of equipment:

- drawing up a drawing - most often the optimal ready-made version is taken and adapted to certain conditions;

- selection of materials - the grade, steel thickness are taken into account;

- creation of a device according to the scheme.

During welding, it is important to ensure that the seams are tight and secure. To adjust the position, legs are welded to the bottom, which, if necessary, change the height. After preparing the boiler, control tests are carried out, where the capacity is gradually increased.

For uniform distribution, the flow of fuel, automation is used, which is implemented in specialized retail outlets.

Boiler and chimney installation

Wires, oil hoses are insulated so that there is no direct contact with the hot boiler. Thermal sensors are mounted on the side of the tube, the container with the mining is placed within 1.5 meters from the heated surface of the structure.

When installing the chimney, the following rules are observed:

- diameter corresponds to the pipe outlet;

- the thickness of the metal pipe is not less than 0.5 mm;

- no more than three turns;

- the height is not less than 5 meters.

The chimney should rise above the roof.

Features of operation

During operation, in order to extend the service life of the equipment, it is necessary to regularly carry out the following measures:

- cleaning the combustion chamber;

- cleaning the oil supply tube;

- dust purging of automation.

You also need to follow all the manufacturer's recommendations.

A self-made boiler for working off must be safe. The device must be placed at a distance from combustible objects, materials. Since during the operation of the boiler there is an increased burnout of oxygen, it is important to provide the room with ventilation and a chimney with draft regulation.A protective casing is placed at the intersection of the chimney with the roof.