In country houses and apartments with forced heating communications, heat is unevenly supplied to the rooms. In order to increase the speed of the coolant, a circulation pump for heating is used. To choose the right device, you need to know the nuances of selection, design and design parameters.

- Purpose of using the circulation pump

- Design features

- The principle of operation of the circulation pump

- Pump classification

- Wet rotor models

- Dry rotor devices for heating boilers

- Selection of the pump for the DHW system

- Device Specifications

- Selection of a pump for a private house according to technical characteristics

- Pressure

- Power

- Performance

- Parameters

- Overview of models of circulation pumps from popular manufacturers

- Grundfos UPS

- Wilo Star-RS

- DAB VA

Purpose of using the circulation pump

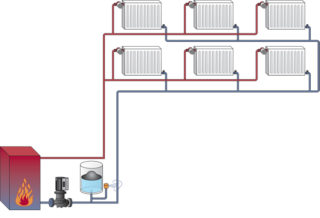

The circular type of pumps refers to devices operating in a closed-loop heating system. It is necessary to move the coolant through the pipes and maintain the selected temperature. The device is intended for the following purposes:

- achievement of the design capacity of systems with forced circulation type

- improving the energy efficiency of equipment;

- acceleration of the natural circulation process;

- performing the functions of pumping devices of a heat generator;

- adjustment of the parameters of a separate battery in two-pipe systems;

- overcoming the inertia of autonomous communications with a natural type of circulation;

- the direction of the coolant in a closed loop.

The pump does not compensate for the loss of the coolant and does not fill the line.

Design features

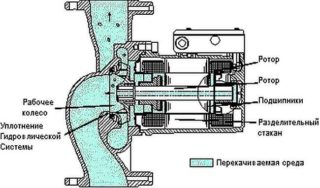

The pump used for the heating utility boiler looks like a drainage device. The design of the equipment is represented by a housing made of stainless steel, aluminum, cast iron and electrical elements in the form of a stator with a winding and an integrated rotor. The part is made of steel.

There is a fixed impeller on the moving part of the engine (shaft). The wheel consists of two parallel discs connected by radial blades. On one of the disks there is a hole where the liquid coolant flows, on the other there is a cavity that fixes the impeller on the motor shaft.

The electric motor is manufactured with a control board and terminals for connecting a cable. Models without electronics are equipped with a capacitor and a speed selector on the terminal box.

The principle of operation of the circulation pump

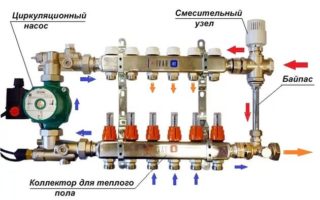

When using a circulation pump, the performance of DHW systems and an autonomous heating main is increased. You can consider the operation of the unit using the example of a collector group for a warm floor:

- The flow of the coolant into the inlet pipe.

- Supply of electricity and transmission of torque from the rotor to the turbine wheel.

- Rotation, creation of vacuum in the pipe and pumping of the coolant by the impeller.

- Movement of water by means of inclined blades at the moment of torsion.

- The movement of water to the edge of the disc - a centrifugal type of force is involved.

- Water intake from one side and pumping out in the heating communication in a continuous mode.

- Increasing pressure, overcoming resistance in different zones of the circuit.

The heating medium will circulate until the pump stops.

Pump classification

Home type of communications or heating of a multi-storey building allows the installation of units with various solutions of the "turbine-rotor" unit.

Wet rotor models

The impeller and rotor are in constant contact with the working coolant. Water lubricates the elements of the device and simultaneously cools it. The rotor and stator area is separated by a containment vessel. The speed is set by a step regulator, which is convenient for controlling energy consumption.

The modular design simplifies repair and selection of parts to increase the head. The engine does not require cooling when exposed to water continuously. Wet rotor versions have several advantages:

- minimum noise level;

- compactness and light weight;

- reduction in energy consumption;

- ease of setup and maintenance;

- long operational period.

The disadvantage of blowers is the wear of hydraulic mechanisms in the presence of small abrasive particles in the water.

Dry rotor devices for heating boilers

Pumps provide pumping of large volumes of coolant in the absence of contact between the rotor and water. The body is made of cast iron or steel, coated with anti-corrosive compounds. There is a seal in the form of static and dynamic rings between the motor and the pump unit. The difference between pumps with a dry rotor is 85% efficiency.

The following models are suitable for use in an apartment building:

- Monoblocks. The motor and pump are located in one unit, which simplifies maintenance and operation.

- Console. The axes of the motor and the pump unit have a common line. The suction tube is located on the volute, the discharge tube is opposite it, on the body.

- In-line. Installation is carried out on the pipeline. The suction and pressure connections are in one line. The seal compensation mechanism is automatic.

- Twinned. They work together or separately. One unit turns on when the second breaks down - the boiler operates in continuous mode.

Dry rotor blowers are characterized by efficiency and maintainability. They are undemanding to the composition of the coolant.

Dry models make a lot of noise, so they need to be installed in a separate boiler room.

Selection of the pump for the DHW system

The recirculation pump is suitable for heating and solves the problem of supplying domestic hot water for household needs. To get a good machine, you need to take into account:

- Noise during operation. In residential premises, low-noise options are advisable.

- The head of the coolant when supplying. With a horizontal hot water supply circuit, a water column height of 50 to 80 cm will be required.A vertical circuit requires an indicator of 80 cm.

- Energy consumption. Depends on power parameters.

DHW equipment can be installed in a classic heating circuit or in a warm water floor.

Device Specifications

Knowing the characteristics of the circulation pump will help you find a suitable option for home or apartment heating. When buying, the following parameters are taken into account:

- head - a technical parameter that determines the rise of water to a certain level;

- consumption and performance indicator - the amount of coolant supplied over a certain time;

- mounting dimensions - the size of the device that allows you to determine the possibility of inserting into the pipeline.

There are digital and numeric markers on the front of the case:

- variety - circulating blowers are designated as UP;

- speed control - models with single-speed mode are not indexed, S means step switching, E - smooth frequency;

- inner pipe diameter in mm;

- head - depending on the manufacturer, it is marked in meters or decimeters.

From the information on the front panel, you can determine the type of case.N indicates that stainless steel was used, cast iron is not indexed, A - about the presence of a union for the drain, K - about the possibility of using it for systems with cold water, KU - for cold, but with a foam filler for the stator and terminal box.

Selection of a pump for a private house according to technical characteristics

The correct selection of pumping equipment is based on calculations based on several criteria.

Pressure

You will need to know the total length of the water pumping line. For every 10 m of pipe length, 0.6 m of head is required. That is, a private household with a heating circuit of 70 m provides a blower with a head of 4.2 m.

Power

You can calculate the power on the basis of SNiP 2.04.07-86:

- for houses with a height of 2 floors - from 173 to 177 W / m2;

- for buildings with 3-4 floors - from 97 to 101 W / m2.

For the selection of devices, taking into account thermal insulation, wear and tear of buildings, use the table.

| power, kWt | Room volume in new buildings, m3 | Room volume in old buildings |

| 5 | 70-150 | 60-110 |

| 10 | 150-320 | 130-220 |

| 20 | 320-600 | 240-440 |

| 30 | 650-1000 | 460-650 |

| 40 | 1050-1300 | 650-890 |

| 50 | 1350-1600 | 900-1100 |

Performance

To calculate performance, you need to apply the formula Q = 0.86R / TF – TRwhere:

- Q - consumption per hour of the coolant in cubic meters;

- R - thermal power spent on heating;

- TF - temperature indicator of water at the inlet;

- TR - temperature indicator on the return line.

The thermal power factor depends on the climatic conditions of the area. A private house in the European climatic zone with a small square area provides for the cost of 100 kW for heating 1 square. In apartment buildings, 70 kW is spent per square meter.

Parameters

When calculating the external parameters of the pump, you will need to take into account the features of communications:

- models 18 cm in length are placed on pipelines, mixers and bypasses of floor type;

- blowers 13 cm in length are placed inside heat generators or a small line;

- the diameter of the nozzles depends on the section of the main pipe, you can increase the dimensions;

- for primary rings and boiler circuits, gravity lines, versions with 32 mm diameter nozzles are suitable.

In stores, there are mainly bypasses for a standard pump 18 cm in length.

Overview of models of circulation pumps from popular manufacturers

Comparing injection devices is possible not only in terms of parameters. The selection also involves studying information about models from well-known manufacturers.

Grundfos UPS

Quality device equipped with ceramic bearings, stainless steel sleeves and composite wheels. Grundofs mainly produces wet rotor models, which differ:

- energy efficiency - consume 45-220 W;

- the minimum noise level not exceeding 43 dB;

- operating temperature range from 2 to 110 degrees;

- ease of installation and maintenance;

- compactness and light weight.

Grundfos equipment cannot be called budgetary.

Wilo Star-RS

The series is distinguished by the reliability of components and electronic circuits. Wilo is an economical model with power control modes, cast iron casing, polypropylene turbines. Stainless steel is used for shafts, metallographite for bearings. Features of the units:

- ease of installation;

- work at temperatures from -10 to +110 degrees;

- the presence of a protection system against voltage fluctuations.

The pumps are noisy at high speed.

DAB VA

Italian equipment should be chosen for operation in domestic conditions. Die-cast aluminum motor, technopolymer turbine ring, ceramic shaft and bearing. Features of devices:

- three modes of speed regulation;

- quick-release mounting clamps;

- installation dimensions 130 and 180 mm;

- noise level up to 70 dB.

Bushings are made of graphite.

Circulation pumps are required if a closed heating circuit is laid in the house, radial wiring or a water floor is made. Taking into account the characteristics, features of the model range of manufacturers, it is easy to find suitable equipment.