The modernized cast iron boiler KChM of domestic production is a solid competitor to Western units. It is unlimitedly used for heating houses, cottages, summer cottages, industrial facilities. The equipment serves from 25 to 30 years, subject to the rules of operation. The solid fuel boiler runs on wood, coal, peat, after a simple re-equipment it uses gas, oil, electricity.

About the manufacturer

The Kirov plant for the production of sanitary and heating equipment was founded in 1745 by the brothers Zolotarev and Faleev. Merchants and industrialists laid the foundation for the first workshops of a hammer plant on the river in Kaluga province.

The small business gradually developed into a large company, using advanced technology in its work together with the time-tested features of iron casting. The modernization of assembly lines and the use of highly qualified specialists bring the quality of the units to a high level. Since 2006 the company has been a member of Santo-Holding OJSC.

Equipment feature

The advantage of the modernized cast iron equipment is its versatility. Boilers are manufactured to work with solid fuels, but they are converted into gas units or work on oil extraction. Re-equipment is carried out without impressive material costs - a set of parts is purchased that are assembled on their own.

The burner is set up within half an hour and is just as quickly dismantled when returned to wood or coal. The boilers are manufactured in Russia, so spare parts are purchased without problems at a low price. The models differ in technical characteristics and are suitable for work in a private house or industrial workshop.

Installation of boilers KChM

The universal device is installed in gravity open heating systems and closed pipelines with a circulation pump.

The equipment includes structural elements:

- heat exchanger sections, their number depends on the modification;

- ash, loading and blasting chamber with doors for traction control and oxygen supply;

- chimney pipe on the rear wall with a damper to coordinate the flow of combustion products.

The casing of the unit is covered with a layer of thermal insulation to prevent cooling. The temperature is regulated by a temperature sensor located in the middle part.

Advantages and disadvantages

The structure does not have complex parts, it can be easily repaired and cleaned. The efficiency reaches 77-79%.

The main positive qualities:

- long service life;

- reliability and versatility;

- always good smoke draft, thanks to the automatic regulator;

- wide range of power;

- high working pressure;

- low cost.

The disadvantages include the absence of an electric factory heating element in the design. The units are not intended for servicing the heating main and the hot water circuit at the same time. The boiler is heavy and large.

Technical characteristics of KChM boilers

Powerful models are equipped with an automatic valve to protect against overpressure in emergency situations.

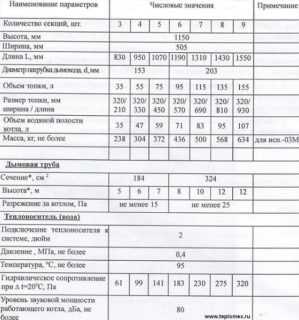

The main characteristics of the boiler:

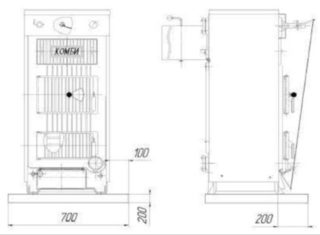

- body width and height 75 x 110 cm, unit weighs up to 240 kg, wall thickness - 12 mm;

- water is heated in a heat exchanger up to + 95 ° С, liquid pressure - 0.4 MPa;

- number of sections from 3 to 7;

- the firebox of the smaller model with 3 sections is 35 liters, and in the 9-section unit it is increased to 155 liters;

- coal consumption, depending on the capacity, ranges from 2.2 to 9.1 kg / h.

In large furnaces, from 20 kg of fuel are simultaneously loaded, while the boiler operates continuously for 10 - 12 hours.

Boiler power

The combustion chamber gives out about 26-40 kW of thermal energy, at the outlet from the heater, a power of 21-36 kW is obtained.

This makes it possible to heat the area:

- 3-section units - up to 200 m2;

- 4-section - 200 - 300 m2;

- 5-section - 300 - 400 m2;

- 6-section - 400 - 500 m2;

- 7-sectional - 500 - 600 m2;

- 8-sectional - 600 - 700 m2;

- 9-section - up to 800 m2.

The number of cast iron compartments determines the power of the heating equipment.

The principle of operation of KChM boilers

The structure of the firebox limits the air supply inside. Fuel is loaded into the working chamber and burned under conditions of rarefied oxygen, resulting in the release of coke oven gas. The design of the chimney allows combustion products to additionally participate in heating before being discharged to the outside. The fuel is used efficiently and the amount of incombustible residues is reduced.

Sometimes a leak appears at the nipple joints - this indicates a loosening of the nuts. The malfunction is eliminated by tightening the hardware. If condensation falls on the walls of the sections, depressurization has occurred due to the fault of the manufacturer or the user. A consultant is invited. In the boiler, the reflectors of the loading and scraper doors, a shield, an igniter, a thermocouple and a thermostat quickly wear out.

Installation and operation rules

The unit is placed in a separate room with forced ventilation and a smoke evacuation system. A base is concreted under the boiler, the surface of which is made at a horizontal level.

Equipment installation rules:

- distance to combustible objects and walls made of flammable materials - not less than 40 cm;

- the unoccupied space in front of the boiler is at least 3 m, and the gap to the load-bearing walls is from 25 cm;

- the diameter of the chimney varies from 155 to 210 mm, depending on the power of the unit, and the height of the chimney is from 5 m.

The air inflow at the time of start-up is regulated by a flap at the top of the pipe, this element also coordinates the intensity of carbon monoxide removal during operation. The boiler efficiently operates on anthracite fraction 50 - 60 mm, while the consumption per hour is 3 kg. Coarse fractions (up to 80 mm) require stronger traction.

Loading of mixed mixtures with the addition of sawdust is allowed, coal and peat briquettes, fine-grained mass are used. Crude fuel is not recommended.

Types of KChM boilers for housing

Units with automated solid fuel combustion are used for heating private buildings, outbuildings and communal buildings, in which there are pipelines with forced or natural circulation of the coolant.

A cast iron boiler is selected depending on the area of the building. Powerful equipment in a small space leads to heat loss.

KCHM Micro

The unit includes three cast-iron sections, its capacity is 17 kW on anthracite and 14 kW on wood. The boiler is purchased for heating a house with an area of up to 200 m2. The efficiency reaches 79%, and the volume of the combustion chamber is 30 liters.

Approximate consumption of a conventional type of fuel is 2.2 kg / h. The dimensions of the case are 630 x 400 mm, the volume of the water compartment is 16 liters, the unit weighs 158 - 162 kg.

KCHM 5

The boiler is available with several options for the number of sections; the design includes a draft regulator. The equipment is intended for buildings with a total area of 300 - 500 m2, with a capacity of up to 50 kW. The efficiency of the unit is never less than 78.8%. The volume of the combustion compartment is 95 liters. The draft regulator makes it possible to save fuel due to its long burning.