Linoleum is the most popular flooring. It is strong, durable, easy to install and maintain, has a huge selection of different colors. However, there is a disadvantage of such a coating - it is not warm. Therefore, in the process of laying, you will need insulation for the floor under the linoleum.

Insulation materials and technology

There is a wide selection of linoleum on the flooring market. Its main types:

- Baseless - a thin coating that requires careful floor preparation. The slightest irregularities, if not eliminated, will lead to rubbing and tearing of the material. The service life of such a coating is about five years.

- On the basis of felt or jute, covered with a polymer layer. This type of coating has a thickness of up to 5 mm. The base can be natural or artificial. Such material is elastic, soft and will retain enough heat. Suitable for dry rooms with low traffic. For example, for bedrooms. The service life, subject to the manufacturer's recommendations, is 8-10 years.

- Foam-based. Has a thickness of 1.5-3 mm. Slightly retains heat and is able to absorb sounds. This type of coating is easy to install, because easily cut with a knife and glued in the right places to the base. Often, such a coating has an additional layer - fiberglass, which prevents the formation of dents. The surface is covered with a durable film that extends the service life up to 10-15 years.

Even if the coating with the base has thermal insulation properties, this is not enough. It is required to additionally lay insulation on the floor.

Correctly selected insulation material will help keep warm in the room, create additional sound insulation, and hide floor irregularities. Properly executed installation of all materials will extend the service life of any type of linoleum.

Insulation selection criteria and types of substrates

When choosing a heater for linoleum, the following parameters must be taken into account:

- environmental friendliness and safety,

- ease of installation,

- vapor permeability,

- fire protection,

- resistance to mechanical damage.

For floor insulation in a private house with a basement or for apartments on the ground floor, you must first select a substrate. It compensates for unevenness of the base, muffles sounds, retains heat. There are several options for natural substrates, they are environmentally friendly and completely safe:

- Cork - pressed small particles of cork bark. The material retains heat well and absorbs noise. It is resistant to moisture, soft - pleasant to walk on. Disadvantages: high cost; due to the softness under heavy furniture, the material bends, which leads to deformation of the floor covering. The latter disadvantage can be avoided by choosing a more rigid version of the cork backing.

- Jute is a natural material consisting of jute fibers. The compressed fibers are impregnated with antifungal and flame retardants. Advantages: the material is resistant to mold formation, has good heat and sound insulation properties.

The disadvantages include the high price and deformation with prolonged exposure to heavy objects. - Linseed is made up of natural flax fibers. Like jute, it is processed with fire protection. It also retains heat well and absorbs noise. Linen backing is thinner than jute, so it deforms less under the influence of furniture. The price is about the same as that of jute.

The combined backing of jute, linen and wool allows you to combine all the advantages of the components and achieve the maximum density of the material. Such a substrate is less susceptible to deformation, and its cost is lower than others.

Types of heaters

It is recommended to insulate the floor with penoplex or isolon.

Penoplex or extruded polystyrene foam is a heat-insulating material with a porous structure. It is easy to use - the slabs are easily cut with an ordinary knife. Possesses high heat and sound insulating properties. The material is safe and durable.

Izolon or polyethylene foam is not foil-clad and foil-clad. The foil can be on one or both sides. Such insulation has high rates of steam and heat insulation, waterproof, safe, durable. In addition, the price of isolon is low.

Another way to insulate the floor under the linoleum in an apartment or in a private house is the "warm floor" system. There are the following types:

- water;

- cable;

- infrared.

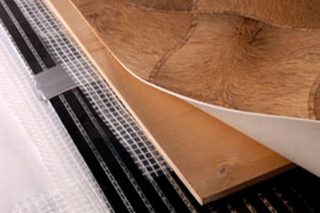

The best option for a warm floor for placement under linoleum is infrared. The film system takes up little space. The warm floor is laid on a substrate, covered with moisture-resistant plywood on top. This is followed by the flooring.

IR film for linoleum on a wooden or concrete floor allows you to maintain a comfortable temperature in an apartment or in a private house. In the same way, you can insulate the balcony.

Do-it-yourself insulation technology

If you violate the technology of laying a warm floor, the heat will quickly leave the room. To prevent this from happening, you should adhere to simple rules.

- Before installing linoleum on a wooden floor, you need to prepare the surface. If there are irregularities and cracks, thick plywood (8-12 mm) is laid. If the defects are minor and the boards are in good condition, you can do without it.

- For a private house or for an apartment on the ground floor, a substrate is laid on the prepared base. In this case, it is better to choose a more rigid one so that the installation of heavy furniture does not lead to its deformation.

- Insulation is laid on top of the substrate. The joints of the backing and insulation must not match. The seams between the sheets are glued with construction tape.

- A vapor barrier film and fiberboard sheets are laid on the insulation layer, which are fixed with self-tapping screws. Another layer of vapor barrier should be put on the fiberboard and only then the installation of linoleum should be carried out.

It is not difficult to carry out thermal insulation of the floor in a private house, in an apartment or in a country house with your own hands. It is important to choose the right materials and follow the instructions.