Mineral wool is a natural insulating material that has the ability to keep warm indoors and also keep you cool during hot seasons. There are three types of mineral wool insulation, the characteristics of which are different. It is a common, stone and glass mineral mixture. Depending on the purpose of the building material, you can choose the most suitable properties.

- The composition and technology of mineral wool

- Characteristics of mineral wool

- Strength and density

- Shrinkage

- Thermal conductivity

- Frost resistance

- Soundproofing

- Toxicity

- Fire resistance

- Water absorption and vapor permeability

- Advantages and disadvantages

- Installation methods

- Minvata for floor insulation

- For wall insulation

- Popular manufacturers of mineral wool

- Knauf

- TechnoNicol Rocklight

- Ursa

Mineral wool composition and technology

Mineral wool insulation (stone wool) is made from molten rocks according to a specific method: first, the rock melts, then it is turned into long threads, which then cool down. They are pressed with a binder and cut to size. Depending on the purpose of the purpose, the density of the insulation can vary from 10 to 400 kg / cubic meter. For interior work, a material with a lower density is suitable, for exterior - with a higher density.

For the production of glass wool, not rock is used, but glass industry waste or sand. The production process is similar: the raw material melts, then melted drops of glass fly out of the centrifuge, which, under the influence of steam, turn into filamentary fibers. Compared to mineral wool, glass wool has a higher elasticity and strength.

Slag wool is another type of mineral insulation, the raw material for which is the waste of the metallurgical industry - blast furnace slag. The material is softer than the previous two varieties, therefore it has advantages for warming rounded objects. There are also disadvantages, but with the correct intended use, it serves for at least 50 years without loss of properties.

Characteristics of mineral wool

The most used and durable is the basalt variety of mineral wool, produced from volcanic material. This material has the least drawbacks, and the price allows you to use it for any work:

- insulation of the building facade;

- for laying under the floor to keep warm;

- for roof insulation;

- for sound insulation between rooms with thin plasterboard partitions.

There is mineral wool for insulation with a foil side and non-foil side.

Strength and density

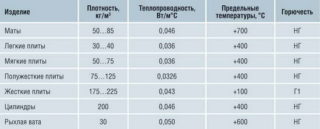

The strength or resistance to dynamic loads depends on the number of vertical fibers. The higher the density, the greater the strength and the higher loads per 1 square meter the material can withstand. For example, with a density of 300 kg / cubic meter, cotton wool can withstand pressure up to 700 kg / square meter.

Density is the amount of fibers in a specific area. As the density increases, the weight of the board increases. Denser specimens are used for outdoor use and under concrete screeds, as they must withstand environmental conditions. The higher the density, the longer the material will retain its original shape, even with a sharp change in temperature.

Shrinkage

The degree of shrinkage of the mineral material - basalt slabs or glass wool - is negligible, therefore they are successfully used to seal pipes - water supply, gas.Over time, the seams remain in place and do not allow water and cold to pass through, circulating the transported substance.

The degree of shrinkage depends on the melting temperature - not combustion, since the material does not burn, but only melts, but it is almost impossible to achieve a temperature of 1500 degrees. For glass wool, this figure is lower - only 500 degrees. For slag wool - 300.

Thermal conductivity

There is only one material that competes with mineral wool in this characteristic - polystyrene foam. The advantage of cotton wool is that it consists of natural ingredients and is cheaper.

A 13 cm layer of mineral wool can replace 1.5 m brickwork, therefore, with this material, it is beneficial to save on construction and heat carrier costs.

Frost resistance

The GOST documents do not indicate frost resistance indicators that manufacturers must comply with, but it is known that glass wool is not recommended to be cooled below 60 degrees, which corresponds to the natural conditions of the Far North. For stone wool, this figure is much higher: cooling to minus 190 degrees does not harm the material in any way.

Soundproofing

Mineral wool can be used to reduce noise levels in a room. Due to the porous structure, sound waves do not propagate at normal speed, but slow it down when passing through the fibrous structure, where the speed and strength of sound decreases significantly.

Toxicity

Due to the presence of phenol-formaldehyde resin binder, it was previously thought that mineral wool can cause health problems when phenol evaporates. Recent studies show that phenol does not evaporate at normal temperatures. Mineral wool insulation has received the 3rd degree of carcinogenicity, which also includes coffee and tea, which are consumed daily by people.

Fire resistance

All types of mineral wool are non-combustible materials, but they have different melting points. The most resistant is basalt wool - its fibers begin to melt after 2 hours of exposure to a temperature of 1000 degrees. After such heating, the material loses its properties and must be replaced, since the fibers are sintered and shrink.

Water absorption and vapor permeability

Basalt slabs and other types of mineral wool are chosen for the low initial moisture content of the material, which contains 1% water. There are specially treated hydrophobized materials that, when fully immersed in water, are capable of absorbing no more than 6% of the liquid. Common types absorb up to 30%.

Steam freely penetrates through the insulation-wool, therefore, when using it for internal work, you can not worry about the presence of condensation on the walls.

Advantages and disadvantages

Like any building material, mineral wool has advantages and disadvantages. The pluses include:

- fire safety;

- no deformation during temperature drops for a long time - up to 50 years;

- low thermal conductivity, maintaining the temperature in a room with insulated walls;

- resistance to chemicals;

- simple installation, available to one person;

- free passage of steam.

Contrary to the opinion that rodents and other pests do not settle inside, they feel good in mineral wool. This is further proof that the material is safe from an environmental point of view.

Disadvantages:

- Compared to foam, which is also used to insulate facades, cotton wool is heavier and therefore more expensive.

- It is necessary to additionally process the material against the accumulation of moisture, but now the industry is already producing hydrophobic varieties that are slightly more expensive than conventional ones.

Most often, the shortcomings of a building material appear if it is incorrectly selected, without taking into account all the criteria for the operation of the object. For example, if you buy glass wool for insulating a chimney, which heats up a lot during the heating season.

Installation methods

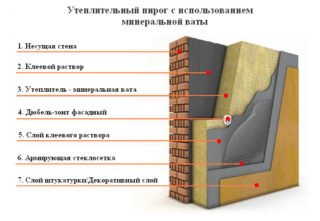

There are two ways to install the insulation material, dry and wet. In the first case, the frame is mounted, then mineral wool is laid in the gaps. In the second, plaster is applied and a plate is glued to it. In the wet process, special adhesives are also used. For insulation of pipes, mineral wool cylinders are used, consisting of two parts, the so-called shell. Fasten the two halves with tape or wrap with wire.

Minvata for floor insulation

The process of floor insulation is as follows:

- Leveling the surface - putty chips and cracks.

- Laying waterproofing.

- Insulation installation. Anchoring to the floor is optional.

- A vapor barrier material so that water molecules can freely pass and not linger between the insulation and the concrete.

- Final screed.

The pouring field can begin to decorate the floor. Dense grades of mineral wool are used that can withstand the pressure of a concrete screed.

For wall insulation

For internal and external work, choose a material with a different degree of density. Wall insulation outside with mineral wool is carried out in the following sequence:

- The thermal conductivity of the wall material is calculated, its characteristics for a specific region.

- A suitable insulation is selected in terms of density and thickness.

- Before installing the insulation, wooden walls are covered with solutions against microorganisms, concrete ones are cleaned of old plaster. It is also necessary to remove all fasteners that could damage the basalt slab.

- A vapor-permeable film is laid on the walls with the porous side to the wall, smooth - outward.

- A profile is installed, in the grooves of which the mineral wool will be laid. The thickness of the grooves must correspond to the thickness of the insulation.

- Additionally, the slabs are fastened with dowels with wide caps, which are placed between the joints.

- A layer of film is placed on top of the insulation, which removes steam from the inside.

- Profiles are installed on the film to organize a ventilated facade. The trim will be attached to them.

If plaster is planned, it is better not to use mineral wool, but to replace it with extruded polystyrene, on which the composition fits well.

Popular manufacturers of mineral wool

The building materials market receives products from both domestic and foreign manufacturers. They differ in composition, properties and price.

Knauf

The company's assortment includes a large selection of heaters that differ in their intended purpose - acoustic, heat-insulating, hydrophobic. Knauf produces slabs and rolls of various sizes, which simplifies installation. The composition does not contain substances such as phenol or acrylic, so the material is considered absolutely safe and can be used in hospitals and child care facilities. The company produces only one type - glass wool.

TechnoNicol Rocklight

The Technonikol Rocklight enterprise is engaged in the manufacture of basalt slabs from igneous rocks. This material is more resistant to environmental influences, which is important for the construction of houses in the middle lane.

Ursa

Ursa company produces thermal insulation materials using sand, that is, glass wool. The main difference is the hydrophobic treatment of slabs and roll materials. There are separate varieties to improve sound insulation, as well as materials adapted for installation under the roof, floor, walls. All products are subject to chemical and radiological control before being sold.