If it is necessary to arrange a warm floor on a wooden floor, there are concerns about the unreliability of a wooden base that needs preparation and additional reinforcement. The description of heating systems, the installation of which is permissible under certain conditions, will help to dispel them.

Choosing the type of warm floor

Before arranging a warm floor, you will need to familiarize yourself with the existing types of heating structures. According to their device and method of obtaining heating energy, they are divided into the following types:

- electrical heating systems;

- water heated floors (TP).

The first of these varieties work on the principle of converting electrical energy into heat; special technical means are used in their arrangement. Water heating floors are a complex structure made of steel or copper tubes with a heat carrier circulating through them. Due to the low thermal conductivity of wood, in this case, preference is given to electrical models that have a high thermal efficiency.

They, in turn, are classified as follows:

- electrical systems called "heating cables";

- film or IR warm floors;

- structures mounted on the basis of heating mats.

Each of the listed varieties has its own advantages and disadvantages, the choice of the one suitable for a particular situation is determined by the preferences of the user himself.

Features of choice

When comparing options for electric floors, the following important points should be noted:

- A typical cable is supplied in the form of coils of a certain length, differing in their heat output. The value of the power developed by such a structure is on average 120-180 W / m2.

- Electric mats as separate elements of underfloor heating are made by laying cable cores on a solid foundation with a certain pitch and have the same heat transfer.

- Infrared floors are equipped on the basis of IR films with electric contacts supplying current located along their edges (the power they develop is 150–220 W / sq. Meter).

In comparison with common water floors, electrical counterparts are easier to install and take up less space in the apartment. When laying them, it is not always necessary to dismantle the rough floor base. They heat up much faster and allow you to set the desired temperature at will.

Electrical structures have a long service life (up to 50 years) and rarely fail. At the same time, when they are installed on a wood base, there is always a risk of short-circuit and the resulting ignition with the possibility of fire. Another disadvantage of such floors is the high current consumption, which forces the owners of the house or apartment to update the existing electrical wiring.

Also, the choice of a heating system depends on what kind of finishing coating is supposed to be laid over the structure. If ceramic tiles are chosen for these purposes, preference is given to mats or a typical heat cable. Under a parquet board or a more plastic and vulnerable laminate, it is more advisable to use an infrared system.

General procedure for installing TP on a wooden floor

The generally accepted procedure for installing a heating system on wooden floors is reduced to the following mandatory procedures:

- Dismantling the old plank covering.

- Replacing rotten floorboards with new samples.

- Reassembling the base while simultaneously insulating it in any convenient way (using stone wool slabs, for example).

- Installation of heating elements (mats, cables or IR films).

- Electrical connection.

- Trial switching on and checking the operation of the heating system.

- Selecting the right material and laying the finishing coat.

- Testing the entire system for performance.

Possible nuances of the upcoming work depend on the selected type of warm floor and the technology of its laying on a prepared base. Each of them has its own advantages and disadvantages, which should be considered in advance.

Pipe-laying options and techniques

There are several known technologies for arranging TP in rooms with floor coverings based on ordinary boards. For an ordinary user, the simplest options associated with installation on logs and laying along special guides (rack and pinion method) are suitable.

Laying option on lags

Arrangement of floors begins with the preparation of a reliable wooden base. If rotten floorboards are found in the existing flooring, they are replaced with fresh boards. Further actions are carried out in the following sequence:

- Along the edges of the repaired floor, two side beams with grooves for transverse support-floors are attached to the brackets.

- First, ready-made logs are placed in them, set strictly in level and fixed in any convenient way.

- After fixing them, the plates of the selected insulation are placed between the individual transverse boards. Most often these are slabs based on foam or basalt wool.

- The heating elements themselves (electric cables, for example) are placed in the grooves prepared in advance, fixed by means of jumpers applied to the set.

Upon completion of the installation of the heat-insulating rug, they begin to design the protective flooring, as which it is allowed to use sheets of moisture-resistant plywood with a thickness of at least 3 cm. On top of the finished base, a finished floor of linoleum or parquet flooring is arranged.

Along the rails

This method is more suitable for water-heated floors. To implement the rack and pinion technology, additional parts will be required, which are used as special guides. In this case, the order of assembly operations looks like this:

- A reliable base is prepared from laid floorboards, damaged or rotted samples of which are replaced with new ones.

- It is carefully leveled, support bars are mounted on top, free niches are covered with mineral wool mats or foam plates.

- A layer of waterproofing is laid on top of them, closed on top with moisture-resistant plywood.

- Ready-made rack and pinion guides are taken, which are stuffed directly onto its surface according to a previously drawn up scheme for laying a "snake" from pipes. The elements of the TP will be fixed in them.

- The resulting gaps are sealed with reflective material.

Separate tubes of a water-heated floor are placed in the prepared grooves, closed from above with a heat-reflecting material. This type of installation of the heating system is quite laborious, but it guarantees the reliability of its functioning and does not require significant expenses from the contractor.

Expert advice

Specialists in installing warm water floors on a wooden floor advise you to adhere to the following recommendations:

- In the turning sections, the sharp corners of the guide rails are pre-rounded, which excludes the possibility of damage to the tubes with the coolant.

- The aluminum foil used for heat retention is selected with a thickness of at least 50 microns.

- During installation, it is pressed into the grooves with force, bending around each recess in them.

- You can prevent the sheets of foil from shifting by fixing them on the slats with a construction stapler.

- For better heat dissipation, the water pipes are also wrapped with aluminum foil before installation.

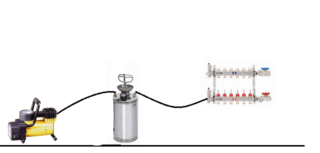

At the end of the main work, the assembled water floor is independently connected to the heating system. At the same time, its mandatory pressure testing is carried out, excluding the possibility of leaks. If no leakage violations were detected during visual inspection, proceed to the next stage of work associated with the installation of the topcoat.

Advantages of underfloor heating on a wooden floor

Installation of TP on the surface of already laid boards with preliminary insulation of the base has a number of advantages, which are manifested:

- The work is carried out according to absolutely "dry" technologies, the implementation of which dispenses with the tedious procedures for mixing and pouring concrete mixtures.

- To prepare the base, it is enough to level the existing coating and lay bars on it under the logs.

- Insulation procedures are simplified, since there are already ready-made niches for laying mats or heat insulator plates.

- The floor itself is much easier to install, since there is no need for special clamps for thermal elements. They are installed and fixed directly on the logs.

Work on the design of the finishing coating (linoleum, for example) is facilitated, so it can be mounted on plywood flooring, fixed on the same slats or logs.

what the fuck is the foil, when there are ready-made heat-distributing plates - galvanized rubles for 40-60 rubles or aluminum plates from 120 rubles to 300 rubles, depending on the manufacturer

the foil will not be able to tightly grip the pert pipe and there will be poor thermal contact - there will still be a thermal "zebra" on the floor