Iron is less and less in demand in the laying of household and industrial communications. The era of steel pipes, due to their inherent disadvantages, is gradually ending. They are replaced by metal-plastic pipes, which have practically no drawbacks, differing in numerous positive characteristics. The idea of using metal-plastic for heating is attractive in many ways, including for self-assembly.

Construction of metal-plastic pipes

Products are not an alloy of several types of raw materials, they are multi-layer structures, where each element performs a specific task.

Metalloplast has the following structure:

- Crosslinked polyethylene or polypropylene. Forms an internal smooth surface, due to which a free flow of liquid is ensured. The material is durable, flexible, resistant to temperature changes.

- An adhesive composition with the same coefficient of thermal expansion as the reinforcing component.

- Aluminum tube. Metal walls are butt welded or overlapped. Metal gives products strength, dimensional retention and protection of polyethylene from contact with oxygen.

- Another layer of adhesive.

- High pressure polyethylene. The plastic is durable and flexible. Provides protection of internal elements from mechanical damage.

Thanks to this design, metal-plastic pipes for heating are able to withstand high pressure and strong heating without loss of performance.

Advantages and disadvantages

Compared to products made from other materials, the bonded combination of plastic and aluminum has the following advantages:

- lack of special conditions for transportation and storage;

- ease of installation;

- sound absorption;

- low specific gravity;

- resistance to corrosion, mold and mildew;

- environmental Safety;

- shape retention with temperature drops;

- reliability and tightness of connections;

- presentable appearance;

- the possibility of laying over a fine finish;

- a wide range of applications, both in private houses and in utility buildings;

- affordable cost, thanks to the automation of the production process and the use of inexpensive raw materials;

- smooth inner surface on which plaque and deposits do not form;

- long service life (at least 50 years).

However, even high-quality metal-plastic pipes Rehau have the following disadvantages:

- on contact with a flame, the plastic ignites and releases toxic substances;

- narrow range of operating temperatures;

- the material melts when heated above 130 degrees;

- limited diameter, maximum cross-section size 63 mm;

- narrowing of the channel at the joints, which leads to a decrease in the speed of water movement;

- the need for periodic tightening of compression fittings, which does not make it possible to make a hidden laying of the pipeline.

A pipe made of metal-plastic is an excellent material in technical respects, which allows you to significantly save energy and money when arranging communications for various purposes.

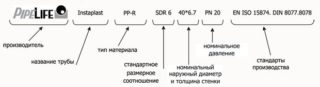

Marking of metal-plastic pipes

Marking on pipes is a decoding of the method of their production, composition and technical characteristics. Values are applied with black ink using an automated printer at the final stage of production. The inscriptions go along the entire length of the product, it is not difficult to find them.

The marking symbols have the following meanings:

- PE-R - polyethylene;

- PP-R - polypropylene;

- PE-X is cross-linked polyethylene at the molecular level.

In turn, stitching methods are denoted by the following letters:

- a - peroxide;

- b - silane;

- c - flow of directed electrons;

- d - azo compounds of molecules.

In addition, the design working pressure (PN) and the product diameter are indicated.

Specifications

Main characteristics of MP pipes:

- outer diameter - 16-63 mm;

- length of one continuous run - 50-200 m;

- thickness of the aluminum layer - 0.15-0.6 mm;

- permissible bending radius - 50-550 mm;

- thermal expansion coefficient - 0.026 mm / m per 1 ºC;

- nominal pressure - 10-20 bar, at a temperature of 95 ºC and 20 ºC, respectively;

- thermal conductivity coefficient - 0.45 W / mK.

The lists are average values. For different manufacturers, they may deviate in one direction or another.

Features of the choice of pipe products from metal-plastic

An integral condition for the manufacture of a reliable and durable circuit is the use of high-quality material in the installation.

When buying it, you should pay attention to the following aspects:

- Appearance. The cut must be perfectly round, the surface is even and uniform, the markings must be clearly marked.

- Dimensions must comply with applicable standards.

- The thickness of the aluminum layer for arranging the heating system is not less than 0.4 mm.

- The reinforcing layer is butt-welded. Such products are stronger and easier to bend.

It is recommended to purchase IP products in specialized stores. The original product is completed with accompanying documents from the manufacturer and dealer. Compliance with the rules for the selection of material eliminates the risk of acquiring a low-grade fake.

Heating installation

Since the heating system contains a hot coolant under high pressure, the connections of individual sections of the circuit must be distinguished by increased reliability and strength.

There are such docking methods:

- Detachable. Corners, couplings, crosses, adapters are reusable, as they are connected to the thread. Docking is done using nuts, collets and sealing material.

- Pressing. Press fittings make the connection one-piece. Docking is done with press tongs by installing a union and a compression sleeve. This method is considered the most reliable and durable.

- Compression. The connection is made using a union, compression ring and union nuts. After assembling the structure, it is tightened with a special wrench. Requires periodic twisting to compensate for plastic shrinkage.

Taking into account the fact that the pipes bend well, you can minimize the number of fittings by bending products with a construction hair dryer. The minimum bending radius is indicated in the accompanying documents for the product.

Connection of metal-plastic and metal pipes

The reinforced-plastic circuit can be diverted from the heating boiler or connected to a common riser. For connection, a special fitting is used, in which one end is equipped with an internal thread, and the other with a slip washer or press sleeve. First, the product is screwed onto a branch pipe with an external thread, the joint is sealed with FUM tape or tow. After that, the sleeve is pushed onto the plastic piece and tightened with a thrust washer. Such a connection is reliable, but requires regular tightening of the thread. If necessary, the fitting can be replaced with a more advanced product.

Plastic pipes for heating are of very limited use. This applies to both metal-plastic pipes and polypropylene. First, the application is very limited in temperature. The use is also limited in diameters. Secondly, metal-plastic pipes have a significant understatement of the diameter at the fittings, and therefore difficulties with the calculation of diameters and the design of heating systems. This refers to large heating systems. Also, the service life of metal-plastic pipes and polypropylene pipes is greatly overestimated by the manufacturer. In reality, metal-plastic pipes serve for heating and hot water supply for 5-12 years. Polypropylene dubs and becomes brittle, and the metal-plastic pipe exfoliates and becomes brittle. The main use of plastic pipes is cold water supply systems, in some cases at low temperatures, up to 50C, hot water systems, as well as heating systems for private houses, cottages, where the pressure is up to 3kg and the temperature is up to 70C. Heating systems "Warm floor" where the temperature of the coolant is not higher than 45C. Also, metal-plastic pipes and polypropylene are well used in compressed air technological pipelines, but again with a reservation, at temperatures not lower than 0С. In the cold, this material also becomes brittle and loses its properties.

Subject to the temperature regime, the metalloplast showed itself excellently with beam wiring. in this case, the underestimation of the diameter on the fittings is not relevant,