Competent insulation of the house plays a decisive role in its energy saving. The most common heat insulators in Russia, Ukraine and Belarus are expanded polystyrene and mineral wool. Relatively recently, domestic consumers got acquainted with a new material that has unique thermotechnical qualities - penoizol. It is a cellular polymer that is used to insulate apartment and private houses, garages and summer cottages.

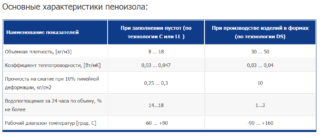

The main characteristics of penoizol

Before giving preference to house insulation with penoizol, it is important to familiarize yourself with its main characteristics.

Heat conductivity

This type of insulation has a very low thermal conductivity. The coefficient ranges from 0.031-0.041 watts per meter per Kelvin. The house will become much warmer, even if a ten-centimeter layer of insulation is laid. This will have a positive effect on heating bills. Over the next few years, all costs will be fully reimbursed.

The foam insulation layer can be from several centimeters to one meter, the decision is made by the owner of the living space.

Fire resistance

Chemical and biological resistance

Most heat insulators are susceptible to mold attacks; in a humid environment, materials are covered with a dense black coating. Penoizol is not affected by any microorganisms. The substance does not react with a chemically aggressive environment and organic solvents. Liquid material can be used to insulate basements and attics.

Ability to absorb moisture

Penoizol absorbs moisture well, but immediately gives it away without any consequences. This is a great advantage in comparison with mineral wool, in which, after getting wet and drying, the quality deteriorates significantly.

It can absorb no more than 1/5 of the moisture, and subsequently evaporates it. In rooms where the material is used, the walls will not get wet, but the ventilation gap must be provided. If you neglect this rule, the development of mold and mildew cannot be avoided.

The material is hygroscopic, which allows the walls to "breathe" freely. This has a beneficial effect on the life of the household and the condition of the house - the walls collapse more slowly. During the day, the insulation is able to absorb from 10 to 20 percent of the moisture in the room. Later, he evaporates it without consequences.

Strength indicators

The materials included in the foam group are technologically advanced due to their softness. They fit snugly to any building structure, even with a large number of irregularities. As a result, voids, gaps, and the "at height" thermal insulation level are not formed.

Durability

Through experiments carried out in laboratory conditions, it was possible to find out that the insulation applied to the structures of the vertical type can last 30-50 years, provided that all the technical rules of application were observed during its application.

Insulation scope

Liquid penoizol is widely used in filling:

- spaces between OSB sheets and concrete base of the floor;

- into the airspace that has formed between two load-bearing walls;

- between the wall and the outer upholstery, for example, profiled sheet, lining, siding and a large number of other materials;

- between the rafter system and the roof covering;

- into a frame on which false walls are assembled from gypsum board sheets or partitions.

The scope of penoizol is quite extensive, due to the large number of advantages of the material.

Advantages and disadvantages

Wall insulation with penoizol gained popularity for a reason. Undeniable advantages:

- high technical characteristics - a layer of insulation with a thickness of 45 mm is already able to prevent heat loss;

- vapor permeability, due to which condensation does not form on the insulated walls, which is very important for wooden structures;

- resistance to dynamic loads - the structure of the material is elastic, which allows it to recover to its original state even after strong compression;

- multifunctionality - insulation can be used for any type of structures, regardless of their geometric shapes;

- neutrality to external influences - the quality of the insulation is not affected by heavy rains or winds, sudden temperature drops;

- high adhesion rates - due to the liquid structure, thermal insulation adheres to all types of structures, fills all voids.

Despite the large number of advantages, do not forget about the disadvantages. The weaknesses of the insulation include:

- low tensile strength indicators - despite the elastic structure, the insulation is easily pierced and torn, which negatively affects the thermal insulation in the future;

- shrinkage - after pouring and hardening, the volume of the material is reduced by 0.1-0.5%;

- dependence on temperature conditions during operation - it is possible to work with the material only if the air temperature is above +5 degrees;

- moisture absorption - if it is required to insulate the foundation, this property should be regarded as a disadvantage.

The disadvantages of insulation with penoizol include high cost. The material itself is not more expensive than its counterparts - mineral wool and expanded polystyrene, but special equipment is needed to work with it, which is rarely found in private developers. For installation work, it is required to rent units, which makes the procedure much more expensive.

About the actual use of anything, penoizol has problems:

1. Incompatibility with wood (physical and probably chemical) - penoizol gives wild shrinkage - you just can't use it without an insulating layer,

2. The release of formaldehyde (carcinogenic) during crystallization, no one writes how much it actually erodes. Plus - that only during crystallization, but a lot depends on the quality of the components of raw materials. Polyfoam and polystyrene are much worse - they release styrene for the entire service life (slowly but surely).