To implement a floor heating system, a whole complex of elements is required. The total length of the floor pipeline can be up to 120 meters, the diameter of the pipes is at least 20 mm in the presence of junctions and turns. In such conditions, hydraulic resistance is created, due to which the circulation of water is impossible without a pump.

Why do you need a pump for a warm floor

Laying the contour implies the presence of bends, which makes the natural flow of fluid impossible. Heating of the coolant does not exceed a temperature of 40 degrees. All this affects the efficiency of the system - any violation leads to the formation of air jams. A pump is needed to solve this problem, although some homeowners are trying to save money by equipping heating without forced circulation.

The underfloor heating pump creates sufficient pressure in the system, pumping water through the pipes. Natural circulation leads to heat loss.

Device and principle of operation

The device includes elements:

- body;

- a motor equipped with an impeller and connected to the housing;

- parts for connecting parts.

Sometimes the pump is equipped with an air outlet, but this is rare. More often they use a special nut - if you unscrew it, the air leaves the system on its own.

The principle of operation of the mechanism is simple: the liquid is directed into the housing, where, due to the rotation of the impeller, it is picked up and thrown out further by pressure. Due to this process, there is a forced circulation of water.

Some pumps have 2 motors installed - so the equipment will continue to circulate even at maximum loads. The second motor is connected as needed and takes over some of the work. Also, the device is considered more reliable due to the reserve. However, equipment with 2 motors is more expensive and the owner will have to decide for himself whether such a purchase is reasonable.

The pump is installed anywhere in the system - usually at the edge of the flow or return circuit. It is recommended to individually choose a place for mounting the overclocking equipment. There are no special requirements - the operating temperature is not critical, but it would be wiser to install the device where it is lower.

Types of circulation pumps

- wet rotor;

- with dry rotor.

Equipment for circulating water in underfloor heating is classified by power - it affects the characteristics of different pumps.

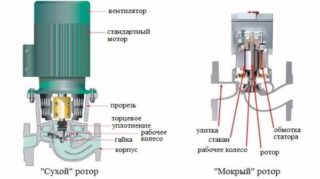

Wet rotor

The impeller is installed as close to the rotor as possible (they are often located in the same housing) - this allows for compactness of the equipment. To prevent liquid from penetrating to the electronics, the drive shaft is equipped with a sealed rubber seal.

Often these pumps have double protection. Models with a wet rotor are small in size, so they are mounted directly in a heated room. They are virtually silent during operation.

The power allows you to run water in the system for buildings with a total area of up to 400 m2. One of the popular models with a wet rotor, suitable for the given characteristics, is Willo. These pumps are quite efficient, but use energy economically, which allows you to reduce the cost of bills.

Small weight and dimensions allow installation directly on the pipes of the heating circuit without the presence of additional fasteners on the supports.All elements must be insulated to eliminate the risk of electric shock. If voltage drops occur, a built-in relay is used - it does not allow the mechanism to fail.

Dry rotor

Each structural part of the pump is located in a separate casing. A "dry" model of sufficient power will easily ensure the circulation of liquid in a system for several apartments.

The equipment is large and requires installation in a separate room. Due to its massiveness, a metal frame will be needed for fastening.

Dry models make a lot of noise during operation, therefore they are rarely used in heating private houses. Such pumps are used in large industrial enterprises or retail outlets.

An obstacle to using a pump with a dry rotor in a private house is often the fact that a three-phase power grid with an internal voltage of 380 V is required for the model to function.

What parameters to choose

- Power. Measured in cubic meters or liters per hour. Should be 3 times the volume of circulating fluid in the system. Recommended productivity - 25% higher than the established level (due to constant operation, the equipment can quickly wear out).

- Ultimate head. The characteristic depends on the length of the pipeline, the diameter of the pipes and the material. If the pressure is not enough, the pump for a warm water floor will start to overheat and quickly fail.

- Dimensions. The smaller model is easier to mount. However, dimensions are far from the point, since compact pumps usually do not differ in power.

- Number of phases. A single-phase motor is enough for a private house. Three-phase devices are used to heat large buildings.

Before buying, you need to make calculations. A model with insufficient power will not run the fluid as it should.

How to calculate the pump

The selection of the model is based on the volume of the heat carrier. Based on this, the hydraulic resistance is calculated. Heat loss is affected by:

- thermal conductivity of materials;

- fences;

- finding a house relative to the cardinal points;

- temperature in the environment.

After calculating the flow rate of the coolant, it is required to determine the resistance parameter in the heated circuit. For this, standard tables are used. When finished, you can start choosing a model.

An example is a pump for a house with an area of 200 m2. Inside the equipment there is a two-pipe system of pipes with a diameter of 32 mm, length - 50 m, material - polypropylene, temperature schedule - 70-90 degrees. The loss is 24 kW at a mass flow rate of 1.03 m3 / h. Further, according to the table, the hydraulic resistance is determined, in this case - 1.8 mbar / linear. m. For a length of 50 meters, you get 90 mbar. It is necessary to add up with the resistance of the system parts, for example, 1 m will come out.As a result, the owner will need a productivity of 1.1 m3 / h with a head of 2 m. Based on the obtained parameters, you can purchase a device with sufficient characteristics.

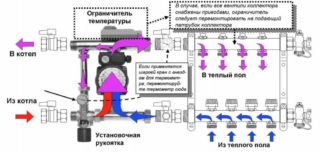

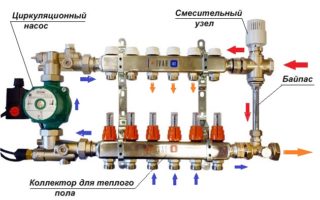

Installation features

The pump is mounted between the 3-way valve and the manifold of the system. Only then will the whole structure work. If you install equipment between the connection to the radiator network and the valve, the mixing unit will not be multifunctional, and heating will be ineffective.

The equipment is fastened to the flanges using union nuts - they are supplied in a box. Installation is usually straightforward if the piping is properly installed, with sufficient distances.

Possible problems

The equipment works in the winter and does not cause problems, but in the summer the pump is idle. Hardness salts begin to build up in the system, especially in the housing.At the onset of the heating season, the engine is activated, but the impeller does not rotate due to a blockage. A low-power motor will not be able to crank it.

It is required to unscrew the nut - there will be a wrench cutout or a screwdriver. Then you will have to manually turn the shaft with the impeller. The main thing is to move the mechanism a little, and then the motor will cope on its own. If it still fails, you will have to disassemble the box and clean the parts from deposits.

With the correct arrangement of the system and the purchase of a pump with the required characteristics, the operation of the underfloor heating will not cause difficulties.