A professional approach to creating a heating scheme is distinguished not only by accurate calculations, but also by the use of all means to improve the system. For this, the individual characteristics of the building, the climatic characteristics of the region and, of course, the level of service comfort are taken into account. An important function in the general scheme is performed by a bypass in the heating system: the purpose, calculation, diameter of this element is mandatory not only when creating a new line, but also when modernizing an old one.

Bypass assignment in the heating system

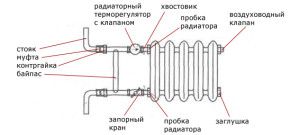

Why is a bypass in the heating system needed and what functions should it perform? Its general purpose is to form a parallel flow bypassing heating components (radiators, valves, circulation pumps). It is a line that connects the conditional inlet outlet pipes of a specific element of the system.

It can serve several functions. For example, a bypass in the heating system of a multi-storey building is required for repair or maintenance work. This is especially true when replacing radiators during the heating season. With its help, you can redirect the flow of the coolant bypassing the battery.

In addition, the parallel transport highway performs the following functions:

- Adjusting the coolant flow to the radiator... By installing the appropriate component (thermal head), you can automatically reduce (increase) the amount of hot water in the battery;

- Upgrading the circuit - another purpose of the bypass in the heating system. First of all, this applies to one-pipe schemes, in which without this element it is impossible to change the level of water flow in the radiator;

- Creation of universal heating... In the event of a power outage, the blades of the circulation pump will make the gravitational movement of the liquid in the pipes almost impossible. But what is the bypass in the heating system for in this case? With its help, a bypass channel is created in which the hydraulic resistance does not interfere with the natural circulation of water.

At first glance, to install an additional channel, you only need a properly shaped branch pipe. But without the right components, it won't function properly. To do this, it is necessary to correctly calculate the diameter of the bypass in the heating system, install shut-off valves. With its help, it is possible to redirect the flow of liquid bypassing a certain component of the system or to exclude the movement of water along the bypass.

When installing a plastic pipe as a bypass into a steel line, the degree of its thermal expansion must be taken into account.

Bypass installation

Knowing how the bypass works in the heating system and why it is needed, you can go to specific examples. Most often, all of it can be found in one-pipe schemes of multi-storey buildings. But besides this, it is widely used in autonomous systems of private houses. For correct installation, it is necessary to calculate the heating bypass and select accessories for it.

Bypass in the radiator trim

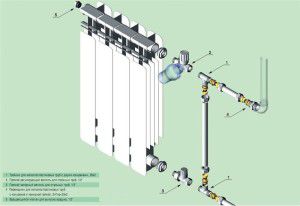

The organization of the bypass channel in the radiator piping is done not only in one-pipe, but also in two-pipe schemes. With its help, it is possible to regulate the flow of the coolant and carry out maintenance and repair work without stopping the boiler or disconnecting from the central heating.

How to make a bypass to the heating system yourself? First, you should make preliminary calculations and choose the right components. It is recommended to use pipes of the same material as for the entire line. The difference will only be in the section. Without fail, the diameter of the bypass in the heating system must be 1 size smaller than the cross-section of the main pipe.

Before self-installation, you should familiarize yourself with the following recommendations:

- Ball valves must be installed as shut-off (shut-off) valves. With their help, you can quickly redirect the coolant to the bypass;

- Installation of a mixing valve is not rational. It effectively mixes cold and hot water in collector systems, where the flow rate of the coolant is initially normalized. For pipelines, and even more so for central heating, this is impossible to achieve;

- Arrangement of a bypass in a one-pipe heating system is mandatory. It is important to coordinate the installation with the management company in advance.

Consumables are purchased for the installation of a parallel pipeline. Let us consider the optimal set of components using the example of a metal-plastic line. Why is a bypass in the heating system necessary in this case? It will function as a bypass circuit for repairing or replacing the radiator, as well as regulating the water flow in the battery section. First, the distance between the direct and return pipes of the radiator is measured. Before making a bypass to the heating system, a pipe is cut to the dimensions obtained. The most common pipe size in autonomous heating is ½. Based on this, components will be selected, the characteristics and cost of which are presented in the table.

| Name | price, rub. | Qty | Amount |

| Reinforced-plastic pipe, m.p. | 23 | 0.5 m | 12 |

| Tee | 75 | 2 pcs. | 150 |

| Male thread adapter | 50 | 2 pcs. | 100 |

| Regulating valve | 448 | 1 PC. | 448 |

| Ball valve | 137 | 2 pcs. | 274 |

| Total | 984 | ||

Before the bypass starts in the heating system, check the reliability of all connections. For this, this section of the pipeline is pressurized, preferably hydraulically. Only then can the pipes be filled with a coolant.

To install a bypass in the heating system of a multi-storey building, you must first shut off the riser to which the radiator is connected. This can only be done by representatives of the management company.

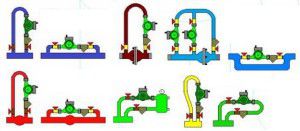

Bypass for installing a circulation pump

Unlike the radiator piping, the purpose of the bypass in a forced-type heating system is to minimize hydraulic losses. For this, the pump is not installed on the return pipe, but directly on the bypass.

What is the bypass in the heating system in this case? It performs the same functions as when strapping a radiator. A distinctive feature is the installation of a non-return valve on the pipe. It is necessary to prevent a change in the direction of the flow of the coolant when the pump is turned off.

In addition, during installation, you need to take into account the following features:

- It is imperative that a bypass is required in an autonomous heating system with forced circulation. Without it, when the electricity is turned off, the speed of movement of the coolant will sharply decrease;

- The optimal diameter of the bypass in the heating system for piping the pump is 2 sizes smaller than the cross-section of the main pipe;

- A mesh filter is installed in front of the pump to prevent debris from entering its mechanism.

It is advisable to use ball valves as shut-off valves. In this node of the circuit, smooth adjustment of the coolant volume is not needed. Most often, it is required to quickly shut off its flow to replace or repair equipment.

The calculation of the pump in the heating bypass is carried out not according to the section of the bypass pipe, but according to the diameter of the main line.

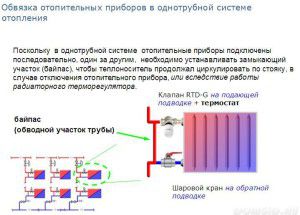

Bypass in the central heating system

The purpose of the bypass in a single-pipe heating system of a multi-storey building is the ability to carry out repair work with a radiator without disconnecting the central riser. For this, the valves are closed and the battery is actually disconnected from the general system without stopping the coolant in the line.

The principle of installing a bypass in a one-pipe heating circuit is almost completely identical to that for the described autonomous one. The difference lies in the peculiarities of the centralized systems, namely:

- In the absence of a bypass line, it can be installed only with the permission of the management company;

- When choosing materials and components, it is necessary to take into account possible hydraulic shocks typical for central heating;

- Installing a thermostat will reduce the heat dissipation of the battery in the event of an elevated room temperature. Alas, the reverse process is impossible - the operation of the bypass in the heating system can only reduce the flow of the coolant, but not increase it.

If there is a likelihood of a low level of coolant in the batteries, you need to install shut-off valves on the bypass. Thus, the entire hot water flow can be redirected along the radiator circuit.

If you make a bypass in the central heating system without a ball valve and a thermostat, the volume of the coolant inflow into the battery will decrease by 20-30%.

To reduce the complexity of work, it is recommended to purchase ready-made bypass units. But before that, you need to do all the calculations for installing a bypass into the heating system - the optimal diameter, a set of accessories, etc. If there are no ready-made structures with the required parameters, you can make it yourself. The best option is to make a bypass to the heating system from metal-plastic.

The video material clearly shows the functional features of the bypass in the heating system: