The comfort of living in a private house and in the country depends on a well-planned, correctly constructed water supply and sewerage system. However, these systems can fail in extreme cold, when the ground freezes to the place where the communications are located. In addition, even with superdeep filling, there are areas that are close to the surface at the points of entry into the building. If you do not insulate the water supply using a heating cable, the liquid in the pipes will freeze. This is fraught with long and expensive repairs.

Design and scope of heating cables

A wire for heating water pipes practically does not differ from a standard electric cable externally and internally. The difference lies in the conductors used.

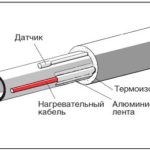

The wire for heating pipes in winter has the following device:

- Internal wire. Differs in good flexibility, is made of alloys with high electrical resistance. The higher this figure is, the more heat is generated. Depending on the model, the electric cable for heating water pipes has one or two cores.

- Polymer insulation. Designed to prevent current leakage into the ground or steel pipe.

- Screen. Made of aluminum foil or copper mesh. Serves to add extra strength to the product.

- Outer shell. Made from dense and durable polyvinyl chloride. Designed to protect the heating element from external damage.

Products vary in thickness, resistance and power per linear meter. The inner conductor is nickel-plated to increase the service life of the heating pipe, which prevents the metal from oxidizing.

Varieties of heating cable

To heat the water supply system, systems consisting of one or two internal conductors are used. In single-wire products, the core acts as a heater and a line at the same time. In two-core cables, one wire heats up, and the other supplies energy.

In addition, heating wires for water supply are divided into two categories, which determine the principle of their operation and scope of application:

- Resistive. These cables are simple in design and consist of one or two cores. Passing through the heating line, the current causes it to heat up. The cable indicators are constant and do not change throughout the entire length of the line. The device is controlled manually, by turning it on and off based on the weather and season. Improvement of systems is carried out by installing a temperature sensor, relay and thermostat. Installation of a heating resistive cable on a pipe is carried out when laying highways of short length, up to 40-50 m. The advantage of models of this type is their reliability, durability and low cost. The disadvantages are that the line cannot be shortened and increased, it is necessary to constantly monitor the temperature, since when it rises, the wire overheats and breaks down.

- Self-regulatory. Products of this type are equipped with a heating matrix that controls the power output. Heating of water supply pipes with a heating self-regulating cable is carried out in an autonomous mode. The operation of the product is based on the principle of changing the resistance of the material when the temperature changes. When it rises, the current decreases, which leads to a decrease in power.When cooling, everything happens the other way around, the resistance increases, the heating increases. The advantage of such models is that the heating of the pipeline with a heating cable occurs zonal, depending on the state of the environment. In critical places, it heats up to the maximum, and in other areas it maintains the optimum temperature. To avoid unnecessary loss of energy, the cables are equipped with automatic regulators tied to the outdoor temperature. The disadvantage of the product is only in its price, but the investment is worth it.

When planning pipeline heating, you need to approach this event in a differentiated manner, correctly selecting various types of heaters for certain areas. The manufacturer's instructions should be read carefully.

Methods of installation on a water supply system

There are several ways to equip heating water pipes from freezing in several ways, each of which is best suited to a specific case.

Do-it-yourself installation of a heating cable for a water supply system can be carried out in the following ways:

- Outside along the pipe. Both resistive and self-regulating models fit in this way. Single-core cables are looped. The line extends along the entire length of the line, is fixed at its end, and then returns to the energy source. It is necessary to place the wires on both sides of the line with an offset to the bottom, to enhance the thermal effect on the liquid passing through it. If there are plumbing fixtures on the track, 2-3 turns are made along it, depending on the size of the product. It is impossible to lay both lines side by side at the bottom, as this will cause them to overheat. Fixation is carried out with heat-resistant plastic ties or aluminum tape.

- In a spiral. The coils are made all over with sticking to the pipes as they are wound. The distance between the turns is determined by the location of the trace. Closer to the surface and above the ground, they are located as often as possible to ensure maximum warming up even in extreme cold. At a depth, the pipe can be wrapped less often, but with the expectation of possible freezing of the soil. Wrapping is done in one or two directions, depending on the purchased model, the length of the line and its operating conditions. Overheating is excluded, since the contact of the lines occurs pointwise. This method is equally effective for both plastic sewer and metal water pipes.

- Interior. This option can be used for pipes with a diameter of 25 mm or more. Resistive and self-regulating single-core models can be used. This is due to the fact that the adjacent location of the cable causes induction and malfunctions of the product, up to and including breakdown. The complexity of this method lies in the difficulty of pulling the wire into the channel. It is better to do this even at the installation stage by pushing the cable into vertically arranged sections or using a pull cable.

When choosing a method of placing insulation, the intensity of the drains should be taken into account. The internal arrangement can significantly slow them down, which will reduce the efficiency of the pipeline.

Thermal insulation of heating cables

Regardless of the cable used, the heated pipe for the water supply needs to be insulated. If the line is not enclosed in an insulating shell, the heat produced will be consumed on the sides, heating the soil, not the pipes.

It is recommended to use the following materials as insulation:

- polystyrene foam in the form of removable cylinders;

- mineral wool with a polymer backing;

- polyurethane foam applied when the cable is installed internally;

- foamed polyethylene wrapped around the channel.

All these products are distinguished by the absence of hygroscopicity, excellent thermal insulation and a long service life.As for the thickness of the insulating layer, 20 mm is sufficient for recessed places, 30-40 mm above the surface, and at least 50 mm in open areas.