Changes in temperature and pressure in the heating system are the main factors for rusting pipes and steel elements. This leads to clogging of the water, which worsens the condition of the radiators, boiler heat exchanger, etc. To avoid this, filters for the heating system are needed: mud, magnetic, sedimentation tanks and similar components.

The relevance of installing heating filters

What else is the reason for the change in the composition of the coolant? Firstly, connecting the make-up unit to the central water supply. In this case, heating mud filters will retain most of the impurities.

In addition, there is another factor in the appearance of foreign elements in the water. Even a thoroughly distilled thermal fluid contains a certain percentage of mineral additives. As the temperature rises, it precipitates, forming limescale deposits on the pipes. With a sufficiently intensive circulation, part of it enters the water in the form of particles of a sufficiently large fraction. The installed filter for the heating system will trap them, thereby leaving the system parameters at the proper level.

What filter elements should an autonomous heating system consist of?

- Pre-coarse cleaning... It is mandatory installed when connected to the central water supply system to make up the system. The optimal model is a filter sump in heating, in the flask of which all foreign components are collected;

- Fine cleaning... With its help, it is possible to delay the advancement of small particles, the size of which is less than 100 microns;

- Additional magnetic filters for heating... On their walls, made of a ferrimagnetic alloy, metallized particles remain - rust, chips from pipes, etc.

The selection of the most suitable filter models for heating must begin with a thorough analysis of each type.

The installation of a mud filter is mandatory, since even in an autonomous system with a well-treated coolant, rust can get into the water from the pipes and the heat exchanger of the boiler.

Coarse water purification with heating filters

The main component of the system for the retention of sufficiently large contaminants is the coarse filter for heating. Depending on the scheme and type of heating, it must be installed in several areas. There are several models of coarse filters, which differ not only structurally, but also in the material of manufacture.

Mud filter

The simplest design is an element that is installed on a specific section of the system. It contains a mesh catcher located in the branch pipe of the structure.

It is mounted on the connection to the central heating system. For stand-alone circuits, its installation is mandatory at branch points, on the return pipe before connecting it to the boiler and on bypasses.

Depending on the design and material of manufacture, the mud filter for the heating system can be of the following types:

- By connection method - threaded, welded or flanged;

- By location - vertical or horizontal.

The most common brass models are designed for a maximum temperature of 150 ° C at a pressure of over 2.5 MPa. Steel types have the same indicators, but they are more susceptible to corrosion.For plastic pipes, there is a polymer filter for the heating system. However, their operating temperature is much lower than for the others - the maximum temperature of the coolant is at around + 90 ° C.

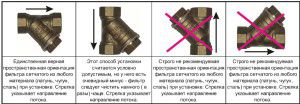

In order for the heating filter to properly perform its function, correct installation is necessary. The direction of movement of the coolant must be indicated on the body of the device. If you set it the other way around, then in addition to the lack of filtration, additional hydraulic resistance will arise.

It is also necessary to periodically clean the mesh from accumulated dirt and debris. For this, there is a screw cap on the outlet pipe that can be removed. But first, you should block the movement of the coolant in this section of the pipeline.

A filter with a grid for the heating system will protect the circulation pump from debris falling into the blades. If it is not installed, then the likelihood of impeller and engine failure increases significantly.

Sump filter

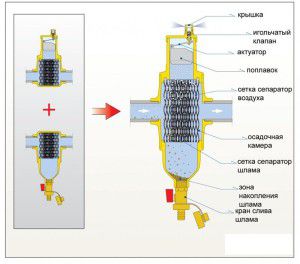

This is an improved model that allows for a long time not to carry out preventive work. The specificity of the design of a dirt filter for heating with a sump is the presence of a flask located at the bottom. Foreign components, lingering on the metal mesh under the action of gravity, sink to its bottom. The flask is made of heat-resistant transparent plastic, which allows you to visually control the degree of contamination of the element.

Often, to reduce the oxygen content in water, a separator is installed in the same housing with a filter for the heating system. When the coolant passes through the filter, air is released, which is concentrated in the upper part of the structure. When a certain pressure value is reached, the drain valve opens.

The advantages and features of installing such a coarse filter model for heating are as follows:

- The ability to visually control the degree of filling of the flask. A tap is installed from below to drain the contaminated liquid;

- Reducing the air content in the water leads to minimization of corrosion processes on the steel elements of the system;

- Installation is carried out almost immediately after the heating boiler. It is in this part of the pipeline that the temperature and pressure of the coolant are maximum, which contributes to the better operation of the separator.

But there is a big difference in cost to consider. The average price of a mud filter for a heating system is about 140 rubles. At the same time, a combined model with an air separator will cost much more - up to 7 thousand rubles.

Be sure to check the material of the flask at the sump filter. It should be a heat-resistant plastic that will not lose its shape when exposed to high temperatures.

Fine filter

In stand-alone systems, it is preferable to install an additional fine filter. It differs from the above types in that a cassette is used as the main component. Depending on the design, it can be either cylindrical or square. The latter is very rare, since the production of such species is associated with certain difficulties.

When choosing, you need to pay attention that the filter model for the heating system is designed for sufficiently high temperatures. If you install an analogue for the water supply, the housing or filter element can be damaged under the influence of hot water. Another factor is the throughput - it should not be less than the calculated head in the system. This is usually 7.2 m³ / hour.

What other parameters are important for a fine filter intended for installation in a heating system?

- Wall mountable... This is important for plastic pipelines, which are not allowed to increase the load due to filling the flask with water;

- Filter element material... For heating, it is best to purchase metal mesh models;

- Maximum values of temperature and pressure.

How relevant is the installation of filters for heating fine cleaning. If preliminary treatment of the coolant has been carried out, you can do without them. In addition, when using antifreeze, the installation of a fine filter is prohibited. The density of the coolant will be much higher than that of water. This will make it more difficult for it to flow through the filter element. The average cost of this component for heating is from 2.2 to 4 thousand rubles.

A slight increase in the budget for the arrangement or modernization of heating with filters (mud, magnetic, sedimentation tanks) will reduce the likelihood of an emergency.

Heating filter magnetic models

Initially, the development of filters for heating systems with a magnet was designed for water supply only. However, their unique performance has contributed to their use in heating applications.

The design consists of two permanent magnets with different poles opposite each other. Metallic elements in water are small, therefore, falling into the field of action of a magnetic filter for heating, they remain on its surface. But how can you clean it up afterwards? In fact, even after 10 years of operation, the level of wall contamination will be extremely low. This will not affect the throughput in this section of the system.

In addition to magnets, the composition may include heating mud filters. But the main selection criterion is the design. It can be of two types:

- Detachable... It consists of two plates installed on the heating pipe. It is characterized by simple installation and quick replacement;

- Non-removable... This is a pipe made from ferrimagnetic alloys. Unlike the above model, monolithic magnetic filters for heating systems have a longer service life, and are also characterized by high magnetic field indicators.

The cost depends on the model, and in particular - its type and size of the magnetic part. The simplest filter with magnets for heating costs about 600 rubles. But a design with optimal operating parameters will cost 4-5 thousand rubles.

Is it worth installing all the described types or is it enough to get by with a coarse filter in heating? Much is determined by the preliminary preparation of the coolant and the material for the manufacture of pipes. For an autonomous system with plastic lines filled with distilled water, a filter with a sump is sufficient. When connecting to central heating, it is best to install all three types, since water in most cases contains a large amount of impurities and pollutants.

Additional nuances of installation and selection of a coarse filter can be found in the video presented.