Heating system operation is impossible without additional components. In addition to heating and distributing hot water to radiators, devices are needed to partially or completely cut off the coolant supply in certain sections of the circuit. For this, taps are installed in the heating system: three-way, ball, battery and radiator.

The main functional tasks of taps for heating

When designing a heat supply system, it is necessary to provide mechanisms for controlling the movement of hot water in the system. To do this, use a balancing valve in the heating system and its shut-off counterpart.

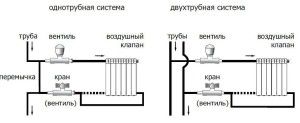

Despite the similar design, some types of valves can perform different functions. So, polypropylene ball valves for heating can be designed both for emergency shutdown of the hot water supply in a certain section of the line, and for regulating the volume of liquid entering the radiator. Therefore, these components of heat supply are conventionally divided into the following types:

- For pipelines... In addition to limiting the flow of the heating medium, the two-way valve for heating performs the function of mixing hot and cold flows. This is necessary to optimize heat distribution;

- Boiler piping... To do this, be sure to use a valve for bleeding air from the heating system, ball valves. In some cases, the installation of three-way mixers is recommended;

- For batteries... Without fail, a Mayevsky crane for heating is installed in the radiator piping. It is designed to remove air locks while filling the system with a coolant.

In addition to the above-mentioned shut-off and control valves, additional components can be installed in the heating system. They are necessary to improve the operation of heat supply and maximum automation of control. In particular, for the prompt removal of water from the system, a tap is required to drain water from the heating system. It is installed at the lowest point in the system.

Before purchasing stop valves, it is necessary to calculate its operational technical parameters. To do this, it is best to use specialized software systems.

Shut-off valves for heat supply

All taps for radiators and pipelines work according to the general principle - with the help of a shut-off element, they limit the flow of coolant in a specific section of pipelines. However, the speed and degree of regulation of this process depend on the specifics of the design of the valves.

First of all, for the correct operation of the system, taps for heating radiators are needed. Depending on the design of the closure element, they are divided into two types:

- Ball;

- Needle-like.

It must be remembered that during the operation of the heat supply, situations may arise when it is required to completely limit the flow of the coolant into the radiators or a section of the pipeline. Ball valves are designed for this. If it is necessary to smoothly adjust the volume of the incoming liquid, a needle valve is installed.

Control valves for heating are characterized not only by dimensions and design data. The materials of manufacture have a great influence on the term and quality of their service.

Ball Valves

If it is necessary to quickly cut off the water, ball valves should be installed in the radiator or pipe section. Their design consists of a spherical core with a through hole. It connects to the control handle, through which the component operates.

Depending on the material of manufacture, it is possible to install a polypropylene ball valve for heating or its steel analogue. It all depends on the heat supply site where it will be installed. In addition to this factor, when choosing, you need to take into account the type of connection. It can be designed for heating radiator taps or pipelines:

- Flanged... They are used in lines of medium and large diameters. Mostly made of steel, its alloys or cast iron;

- Coupling... The most common type of polypropylene ball valves for heat supply. Connection to the pipe section is carried out by means of a permanent connection or by soldering. Adhesive is rarely used to form a mounting assembly.

These valves for heating pipes are characterized by a quick shut-off of the heating medium. It is enough to turn the control handle 90 ° to completely stop the movement of water into the section of the line or the radiator.

During installation, the direction of movement of the coolant must be taken into account. All plastic ball valves for heating have a special indicator on the body.

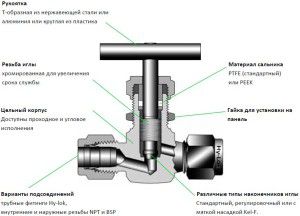

Needle cranes

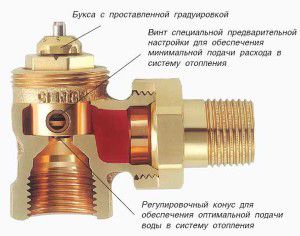

If you need a smooth regulation of the fluid flow, the heating system should provide for the installation of needle taps for heating. Their main difference from spherical ones is the presence of a rod, which, with the help of a threaded mechanism, is lowered or raised, thereby reducing the throughput in this section of the pipeline.

Depending on the field of application, this type of valve is shut-off, regulating or balancing. The difference in design is determined by the shape of the needle rod, the characteristics of the threaded regulating element. Most valves for heating radiators have a standard design and are designed to smoothly adjust the flow of the heating medium.

When choosing, it is recommended to pay attention to the following characteristics of needle fittings for heat supply:

- Connection type - coupling or flange;

- The degree of stem position adjustment;

- Manufacturing material. In polypropylene pipes, the installation of plastic taps for heating is required. If steel lines are installed in the system, then the shut-off valves should be chosen from the same material of manufacture. This will avoid the difference in thermal expansion of the components.

The use of these structures as taps for draining water from the heating system is not recommended. In this case, ball models would be the best option.

All taps for heating batteries are designed for a certain indicator of maximum and optimal pressure. This characteristic must correspond to the calculated one. Otherwise, the system will depressurize.

Mixing devices

For optimal operation of the heating supply, heating control valves are installed. Their main difference from the above-described models is the presence of an automatic water flow control unit. Such structures are most often installed in mixing units.

These types of fittings differ from standard valves in the presence of additional control elements, as well as in the number of connected branch pipes. A standard three-way valve for heating has three connections.Moreover, each of them performs its own functions:

To choose the optimal model, you should decide on its purpose, which can be of the following types:

- Organization of automatic regulation of fluid flow to a radiator or battery. For this, a two-way valve for heating is intended;

- Installation of the mixing unit. For him, three-way taps for heating are most often used.

To understand the principle of operation of each of them, you must first understand the specifics of the design. It is she who determines the operational and technical characteristics of these heating components.

For the full operation of the three-way control valve, it is necessary to connect the thermometer to its control unit.

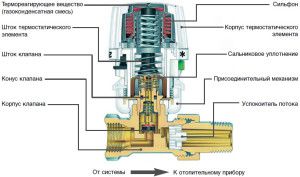

Two-way valve for heating

In fact, this is a conventional needle valve, in which, instead of a mechanical valve, an automatic stem position change unit is installed. It is designed for strapping heating batteries. To be able to respond to the degree of heating of the device, each radiator must be equipped with a heating control valve.

There is a division of models according to the type of control block. The most common type of two-way tap for heating is a thermostat. It has a control element that expands with temperature. During this process, the stem is displaced, thereby changing the throughput in this section of the pipe. Such designs are installed for heating radiators.

However, there is not always a need for such taps for heating pipes. Depending on the required control level, the following types of two-way heating components are distinguished:

- With mechanical control unit... It has markings corresponding to the degree of change in the nominal bore in the pipe. Convenient for manual heating control;

- Servo mechanism with the ability to connect to temperature sensors or programmer... For such control valves for heating, maximum automation of control is characteristic.

When choosing, it is important to pay attention to the design of the control drives. They can be two-position (open-close) or with a smooth change in the position of the stem. It all depends on the purpose of the two-way valve for heat supply.

Similar control structures are installed in the manifolds to automatically regulate the coolant flow. They have proven themselves well in the presence of flow meters.

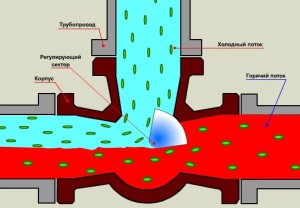

Three-way valve for heating supply

Three-way structures are one of the types of heat supply control valves. Their main difference from the above models is the presence of an additional branch pipe.

For operation, the three-way valve is connected to the supply and return pipes. With the help of the control unit, the position of the damper is changed, thereby regulating the flow of chilled liquid into the supply pipe. This principle of operation allows you to solve the following tasks:

- Reducing the cost of heating the coolant... Temperature sensors connected to the control units of plastic valves for heat supply automatically change the heating operation mode depending on external factors;

- System pressure stabilization... In the case of a large difference in the degree of expansion of the water, the hydraulic resistance will increase. Installing a balancing valve in the heating system will solve this problem;

- Automatic regulation of thermal operating modes heating circuits depending on the previously set parameters.

The choice of control units for the device is completely similar to two-way valves for heating pipes. The only difference is in the form of the flow control element. If in two-way it is a stem, then in three-way models a special plate is used.Depending on its position, the quantitative ratio of hot and cold flows changes.

To complete the heating system, it is best to use copper models of mixing taps. But the best choice would be products made of stainless steel.

Heating control and safety

In addition to the regulating function, there is a group of taps that are responsible for protecting and controlling heating. They are installed in critical areas of the system - in supply pipes, radiators and batteries. In particular, a valve for bleeding air from the heating system is installed directly after the boiler. In the collector heat supply, each manifold must be equipped with it.

These system components are required to perform the following functions:

- Removing air when the coolant overheats;

- Preventing air pockets in the radiator or battery.

To fully understand the functional features of security groups, you need to consider the design of each element.

Some models of gas boilers have built-in balancing valves. You can find out their presence from the content of the accompanying documentation.

Description of the Mayevsky crane

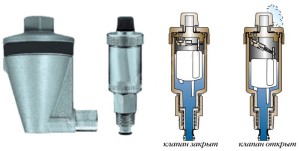

Mayevsky's taps for heating are designed to remove air locks during filling the system with a coolant or during the operation of heat supply. They are a tapered screw that is enclosed in a housing.

The place of installation of this valve is the upper part of the radiator. When adding water to the system, release the spring pressure on the screw. This creates a small passage through which the air lock exits. Depending on the specifics of the design, the Mayevsky crane can be of the following types:

- Mechanical... The adjustment is carried out in manual mode;

- Auto... The special device is triggered by the opening of the valve. As a result, the air lock is removed.

The first type of taps is most often used to complete heating. However, they have one significant drawback. During prolonged downtime, the screw sticks to the base of the case. Therefore, it is recommended to check the tap performance 2-3 times a season, regardless of whether the system is filled with water or not.

For centralized heating systems, it is best to choose a Mayevsky crane model with a fuse.

Air vent

Air often accumulates in the heating system. There are several reasons for its appearance - water boiling, an initially high oxygen content in the liquid. If the excess air is not removed in time, heat supply components may suffer, and rusting of metal elements will begin. It can also lead to an increase in pressure and, as a result, the creation of emergency situations.

Structurally, the valve for removing air from the system consists of a body with a float inside. If air enters the cavity, the float rises, which will press on the stem. This will provoke the opening of the valve and the release of excess gas.

When choosing and installing, you need to consider the following points:

- Nominal opening pressure of the device... Can be set by the user or fixed;

- Place of installation... A mandatory element for the safety group, where, in addition to it, a drain valve and a pressure gauge must be present. It is mounted immediately after the boiler, in the upper part of the circuit and on all critical sections of the highway.

It is imperative to check the performance of the air vent before each heating season. To do this, it is enough to manually lift the valve and make sure that it does not stick.

Each type of heating tap has its own purpose. But remember that some of them are interchangeable. The only exceptions are air vents and Mayevsky taps. In all other cases, it can be installed instead of the ball needle.

In the video, you can get acquainted with the principle of operation of the design of a three-way heating valve;