How to improve the efficiency of the heating system? In addition to the standard methods, you can make a small upgrade. It consists in installing additional tanks that can perform various functions. At the same time, it is important to choose the right capacity of the heating system: buffer, storage, storage. The efficiency and the possibility of organizing hot water supply will depend on this.

Heating buffer tank

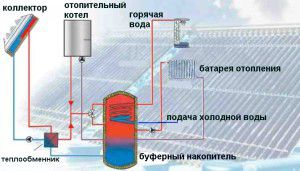

It is a barrel with a coil inside - it is connected to the heating main. Its material is copper or steel. Energy from the coolant through the surface of the coil is transferred to the water in the tank.

Design specifics

At first glance, the storage tank for heating does not have any particular advantages. However, a deep analysis will reveal that the relevance of its installation in an autonomous network is an undeniable factor. What functions does this structure perform?

- Transfer of thermal energy to water, which can be used for hot water supply;

- Increasing the heating operation time even when the boiler is off. For this, one of the pairs of nozzles is connected to the system through two or three-way valves. In this case, the buffer tank of the heating system will mix the cooled coolant with the hot water stored in it;

- Use of heated water for low-temperature heating circuits - underfloor heating.

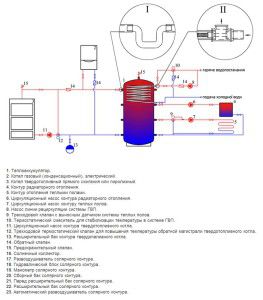

Such possibilities are explained by the design features. All factory buffer tanks for heating have additional insulation circuits. That minimizes the heat transfer of the heated water. Also, the branch pipes have different diameters for commutation with heating circuits.

When choosing a factory model of the capacity of the heating system (buffer, storage or storage), you need to pay attention to the number of nozzles - from 2 to several dozen. Their optimal number depends on the circuits in the system.

Buffer capacity calculation

Any capacity of the heating system, first of all, is characterized by volume. To calculate it, it is recommended to use special programs. If this is not possible, you can make approximate calculations yourself. The heat capacity of water is 4.187 kJ / kg * C. If the heating system has a rated power of 24 kW / h, then the storage tank for heating must keep the system running for 4-8 hours after the boiler is turned off. It is necessary to calculate the volume for the hourly operation of the heating. In this case, the temperature difference should be 70-45 = 25 ° C. Knowing that 1 kW / h is 3600 kJ, you can calculate the capacity:

(24 * 3600) / (4.187 * 25) = 825 kg or 0.825 m³

This is only an approximate calculation scheme, since each capacity of a heating radiator has a number of additional characteristics - heat losses, temperature and humidity in the room, type of heating (gravitational or forced circulation).

What should be considered when choosing a buffer tank for a heating system?

- Its useful volume;

- Heat exchange element area;

- Heat exchanger type - coil or tank in tank. The latter is preferable, since such a design increases the water heating area in the tank.

| Model | Features of the | Price, thousand rubles |

| Austria Email PSF 800 l. | Thermal insulation | 49,175 |

| Bosch BST 1000/80 Sr | Coil | 79,8 |

| Drazice NAD 1000 V1 | Without thermal insulation | 23,2 |

The price of a storage tank for heating is high - the simplest model for 800 costs from 35 thousand rubles, so they often try to make it on their own.

For heating a small private house, installing a container of less than 500 liters is unprofitable. It will not be able to accumulate the required amount of thermal energy.

Do-it-yourself thermal accumulator

The complexity of the manufacture of buffer tanks for heating lies in the creation of reliable thermal insulation. For this, you cannot use an ordinary barrel or a similar container. In addition to this parameter, the capacity of the heating radiator must withstand the load of water on the walls and possible hydraulic shocks.

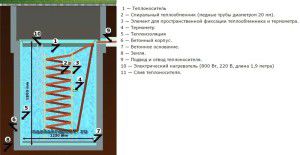

The simplest design is a cube, inside which is a U-shaped pipeline or a coil of copper pipe. The latter is preferable, since it has a large heat exchange surface area, and copper has an optimal thermal conductivity. This design is connected to a common line. For the manufacture of a heating system tank, you will need steel sheets with a thickness of at least 1.5 mm and a metal pipe. Its diameter should be equal to the cross-section of the pipeline in this heating section.

The minimum set of tools includes the following:

- Welding machine;

- Angle grinder (grinder);

- Drill with drills for metal;

- Measuring tool.

The easiest way to make a container for heating radiators is a cubic shape. A preliminary drawing is drawn up, according to which all further work will be carried out. The presence of a heating element is optional, but preferred. He will be able to maintain the level of water heating at the proper level.

The procedure for manufacturing a heat accumulator

First, rectangular sheets are cut out, of which the body of the heating system tank will consist. At this stage, you need to take into account the welding gap - it can be from 1 to 3 mm, depending on the device and the selected electrodes. Then, holes are cut out in the blanks for fastening the pipeline, heating element and nozzles for filling the container. Cast iron radiators cannot be attached directly to it. Therefore, it is necessary to calculate the heat loss from the capacity to the radiator.

After assembling the structure, you need to make the thermal insulation of the case. It is best to use basalt insulation for the heating storage tank. It has the following important qualities:

- Not flammable... Melting occurs at temperatures above 700 ° C;

- Easy to install... Basalt wool is quite elastic;

- Has vapor barrier properties... This is important for the removal of condensate, which will inevitably accumulate on the body of the storage tank during heating operation.

The use of polymeric materials (expanded polystyrene or polystyrene) is unacceptable, since they belong to the flammable group. The thermal insulation of the buffer tank is best done after being connected to the heating system. This way you can reduce heat losses at the inlet and outlet pipes.

An old steel tank can be used as a container. But its wall thickness should not be less than 1.5 mm.

Storage tank installation

The tank is installed in front of the heating radiators. The best option is to connect the inlet pipe immediately after the boiler. According to this scheme, water heating in it will be carried out as quickly as possible.

To ensure maximum safety of the entire system, it is necessary to provide for the installation of the following components of the piping of the heating system tank:

- Shut-off valves on all branch pipes;

- Manometers and thermometers. Temperature sensors should indicate the degree of heating of water in the tank and the heat carrier;

- Sets of 2-way valves for mixing heated water and heating medium from the return pipe, so you can minimize energy costs.

Maintenance of the storage tank must be done before each heating season. It is best to disassemble it completely to remove scale and check the condition of the structure. If this is not possible, rinsing is done with special solutions.

The video describes the advantage of using a storage tank for an autonomous heating system:

Thanks to the author for the interesting article. I myself found out about the heat accumulators after buying a solid fuel boiler, I had to buy it and put it into the finished system. I took a barrel of the Thermiko trademark, made in Ukraine. So far, the impressions are purely positive. The consumption of firewood has decreased by 25 percent, after loading the boiler gives heat for another 6 hours. In general, it has become much more convenient to heat the house. In general, I advise you to look towards the buffer tanks immediately when buying.