Solid fuel heating devices operate on long-flame, coal, brown coal, anthracite and pressed briquettes. The popularity of the equipment is associated with the low cost of installation work, the absence of the need to draw up project documents. The coal-fired boiler can be used for heating, hot water supply or cooking with a hob.

- Benefits of operating a coal boiler

- disadvantages

- The main types of coal-fired boilers

- Automatic models

- Pyrolysis boilers

- Long burning

- Direct combustion

- Materials for the manufacture of the case

- Steel

- Cast iron

- The main criteria for the selection of a coal boiler

- The principle of operation of coal-fired boilers

- Specificity of installation work

- User's manual

Benefits of operating a coal boiler

Modern automatic and semi-automatic models have a number of advantages:

- long-term operation on one fuel tab - from 24 to 48 hours;

- economical consumption of fuel material - coal will need 1.5 times less firewood and 2-3 times less pellets;

- the ability to operate an automatic device for a week;

- reducing the cost of 1 kW of thermal energy;

- profitability - coal fuel is the second cheapest after gas;

- Efficiency depending on the model - from 55 to 90%;

- insignificant amount of smoke during ignition - during operation it is not noticeable.

Firewood, brown rocks with a calorific value from 4500 to 7000 kW / kg and anthracite with a calorific value from 7500 to 9500 kW / kg can be used for filling the firebox.

disadvantages

When choosing a solid fuel unit, you should pay attention to the disadvantages of its operation:

- arrangement of a ventilated boiler room according to fire safety standards;

- labor costs for the organization of the chimney;

- the need for a dry compartment for storing coal;

- risks of chimney clogging and the possibility of cleaning it only with special installations and reagents;

- decrease in the power of the device in the case of using wet coal materials;

- volatility of boilers with forced draft type and automation.

The use of firewood and sawdust affects the power of the unit - the indicator drops by 25-30%.

The main types of coal-fired boilers

You can choose coal heaters according to the principle of operation and by the method of fuel combustion.

Automatic models

The unit is controlled by a microprocessor connected to the regulation system. Automatic types of boilers operate on coal with fractions of up to 50 mm, maintain long-term combustion by means of fan blowers. The combustion products are discharged through the traction system. Fuel loading is carried out automatically through the bunker using a screw conveyor. The features of equipment with automation include:

- reducing the cost of heating - for 1 kW of heat you need to pay from 50 to 80 kopecks, depending on the region;

- efficiency of coal consumption - 1.5-2 times less than standard models;

- efficiency - the real indicator of efficiency is 80-90%;

- complete combustion of fuel 3-4 days after laying;

- equipping with a tank designed for 2-7 days of fuel use.

Smoke in automatic devices is visible only at the moment of ignition.

Pyrolysis boilers

The difference between a pyrolysis coal boiler is a long burning system. It is realized by means of two fireboxes.In the main one, coal is burned, in the additional one - afterburning of pyrolysis gases. The device works as follows:

- Firing up the boiler. The damper is opened completely, then coal with fractions of 0.5-2 cm is set on fire with the help of a small amount of dry firewood.

- Primary fuel combustion. Enough 15-20 minutes.

- Transfer to pyrolysis mode. You will need to close the flap and set the mode.

The pyrolysis reaction begins when the temperature in the furnace reaches 450-600 degrees.

Long burning

The design of the equipment is complicated by a heat exchanger above the firebox. The type of combustion also differs from the standard options - the coal is ignited from above. In comparison with direct combustion models, boilers differ:

- efficiency - fuel material is loaded 2 times less often;

- using only dry coal to prevent condensation;

- impossibility of refueling - weakly sintered rocks are recommended;

- re-laying only when the first burns out completely.

The coal grade is indicated in the manufacturer's instructions.

Direct combustion

Inexpensive options that can be used to heat a small house or cottage. The combustion process takes place from below, the fire gradually spreads through the firebox. Warm air masses move upward, heating the heat exchanger, and then the water type of the circuit.

For models with direct combustion, the maximum efficiency is from 70 to 75%. This is due to the slow heat transfer of heated air masses and their rapid removal through the chimney.

Materials for the manufacture of the case

Manufacturers produce heating units in casings made of various materials.

Steel

Inexpensive options are made from thin sheets. Quality boilers are made of heat-resistant or high-carbon metal with a thickness of 4 mm. The advantages of boilers in a steel casing include:

- withstanding fluctuations in temperature and pressure;

- ease of transportation and installation;

- maintainability - cracks are processed with a welding machine.

The disadvantages of the devices are the risks of corrosion of the heat exchanger, thinning and burning of the walls, the inability to increase power.

Cast iron

The cast iron boiler is made on the basis of bolted cast plates. The joints of the parts are treated with a heat-resistant sealant. Thanks to the design, it is possible to add sections to increase the power. The advantages of boiler plants include:

- corrosion resistance;

- long-term operation - about 50 years;

- heat capacity due to the properties of cast iron and a small heat exchanger;

- maintainability - it is enough to replace or add a section.

The disadvantages of the cast-iron body are cracking during temperature fluctuations, low efficiency and a one-way heat exchanger.

The main criteria for the selection of a coal boiler

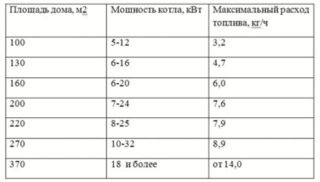

Coal boilers are the best option for houses where there is an individual type of heating main. When buying a unit, several criteria must be taken into account:

- Efficiency indicator. For modifications with direct combustion, it is 65-75%, with long-term combustion - from 78 to 84%, for pyrolysis - from 85 to 92%.

- Work offline. Only pyrolysis devices are completely autonomous.

- Fuel supplement time. Coal is added to boilers of direct combustion 1 time in 6-10 hours. In the presence of an automatic bunker, fuel is supplied to long-term combustion units 1 time in 2 days, to pyrolysis units - 1 time in 4-7 days. Models without automation with long-term operation are refueled every 12-18 hours, with pyrolysis afterburning - every 24-30 hours.

- Permissible moisture content of the fuel. Long-term combustion systems are compatible with 20-30% wet coal, 30-50% wet coal, pyrolysis coal 7-15%.

- Optimal size of fractions.A pyrolysis boiler can accommodate 5-25 mm coal, in long-term combustion - 25-50 mm, in direct combustion - 60-80 mm.

- The number of contours. Devices with one circuit can only be connected to the heating main. Double-circuit modifications work for heating, underfloor heating, connected to hot water supply.

- Furnace capacity. The larger the compartment, the less often you need to lay coal.

- The presence of thermal insulation outside. Insulated boilers retain more heat and do not break with sudden temperature changes.

- The presence of a lining. The lined firebox is economical because depending on the power it consumes 25-45% less fuel.

- Safety system. Provided with an external heat exchanger, an independent cooling circuit with an emergency thermal valve.

- The presence of a heater. A heating element is included in the design of the combined units, which will work after the fuel burns out and the coolant temperature drops.

For the convenience of controlling and monitoring the temperature regime, the boilers are equipped with thermostats, weather-dependent devices, and self-cleaning systems.

The principle of operation of coal-fired boilers

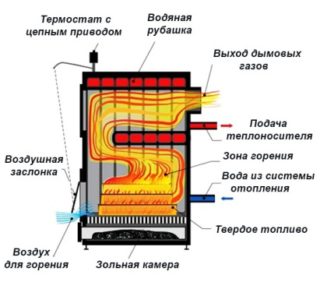

A standard coal-fired boiler is a one-piece lined body. To reduce heat loss, an interlayer of heat-insulating material is used.

On the front, there are three compartments with covers to prevent smoke from entering the room. The lower compartment is an ash pan. The rear panel has an adjustable hole at the bottom - it creates natural or forced draft. The central chamber is a firebox where coal is placed.

A grate is used to separate the lower and central compartments, create a direct current of air masses and remove combustion products. During the combustion reaction, streams of warm air through the pipes go to the upper compartment and heat up the heat exchanger. The heated water is directed through pipes for heating and hot water supply. Temperature parameters are selected by chain controller or electronic mechanism.

Units with manual adjustment need to be laid 4-6 times a day, so it is problematic to control the temperature at night. Automatic boilers are equipped with an auxiliary fuel tank. From one coal load can work up to a week. In this case, the temperature of the coolant does not change.

Specificity of installation work

Installation of solid fuel boilers is carried out without the permission of supervisory services. Users will need to follow a few rules:

- It is better not to install the unit in a residential area - dust, soot and soot will be emitted. Installation is allowed in the corridor, bathroom, in the kitchen, in the bathroom.

- For models with a power of 60-150 kW based on SNiP 42-01-2002, a boiler room with a volume of 15 m3 and more and a ceiling height of 2.5 m is needed.

- Smoke removal and ventilation systems are organized without fail.

- Boilers with a capacity of up to 50 kW are placed on a screed, more than 50 kW - on an individual concrete foundation with a protrusion of 25 cm from the body.

- Ventilation is done in the form of an inlet opposite the boiler. A lattice hood is also required.

- The chimney is made of a pipe with a cross section of 150-200 mm2. It should not have bends, slopes.

- Obligation is performed using a bypass or a three-way valve set for a water temperature of 50-55 degrees.

- The optimal pressure parameter in the circuit is 1 bar.

The return and supply of the gravity line are fed directly to the boiler.

User's manual

The instructions for firing up and operating the coal unit are enclosed with each unit. Regardless of the manufacturer's brand, there are general rules for using a direct combustion boiler:

- Melt the boiler by throwing some coal into the furnace.

- Place paper and small chips on top of the rock.

- Light up the paper. Fire will go from it to firewood, then to the top layer of coal material.

- After crusting, crush the top layer with a poker.This will facilitate the penetration of air to the lower layer.

Further work envisages tossing coal, breaking up sintered pieces and removing slag.

Coal type boilers are an economical solution for a private house and a cottage. Due to the long burning of the fuel, a comfortable temperature is maintained for several hours. Before buying, you need to pay attention to the type of device and its characteristics.