A gas boiler designed for wall mounting is a set of sensors and devices enclosed in one housing. It can be installed in the kitchen, due to its compactness it will not interfere. When choosing a wall-mounted gas boiler, you need to figure out what characteristics affect its performance, which companies produce the most reliable devices, since we are talking about potentially dangerous equipment.

- Number of circuits of wall-mounted gas boilers

- Single-circuit

- Double-circuit

- Varieties according to the principle of work

- Thermal installations

- Pre-heating units

- Specifications

- Advantages and disadvantages

- Features of connection and operation

- Boiler selection criteria

- Popular manufacturers of wall mounted gas boilers

- Reliability rating

Number of circuits of wall-mounted gas boilers

Models of gas boilers differ from each other in the complexity of the device, the principle of operation and cost. The number of heating circuits is of prime importance. This characteristic determines the functionality of the boiler.

Single-circuit

Single-circuit wall-mounted gas boilers are intended for heating only. They have one heat exchanger. The heat carrier heats up due to the heat released during the combustion of gas. Devices are made of steel, copper, cast iron. Copper heat exchangers are the most durable, as they are resistant to corrosion, but expensive. Cast iron will also last a long time, but their drawback is fragility due to shock and sudden changes in temperature, significant weight. Steel heat exchangers are most popular due to their optimal price, weight and service life. Important disadvantages are external condensate corrosion and lower efficiency.

If equipment with steel elements is purchased, preference should be given to a boiler with a heat exchanger made of stainless or alloy steel.

Double-circuit

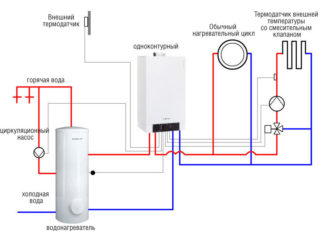

Double-circuit boilers have two heat exchangers, so they are used for heating and to provide a house or apartment with hot water. The devices are compact and do not require a separate installation room. When the secondary heat exchanger is running, the heating circuit is switched off, i.e. DHW is a priority. If hot water is used in a standard volume, the coolant in the heating system does not have time to cool down. This system is realized thanks to the presence of a three-way valve.

Varieties according to the principle of work

Wall-hung gas boilers produced in recent years are complex devices, the efficiency of which designers are trying to increase in all possible ways. There are two types of wall-mounted gas boilers, which differ from each other in the principle of operation.

Thermal installations

The design is represented by two metal tubes inserted into one another. Domestic hot water flows along the inner, smaller diameter, and the outer circuit is intended for the coolant used in the heating system. The peculiarity of such a device is that the inner one heats up from the external circuit.

Advantage: fast heating.

Disadvantages: maximum fuel consumption, excessive thrust.

Pre-heating units

In pre-thermal boilers, the heating circuits for DHW and heating medium are separate, independent of each other. The tubes are usually copper, located on different sides of the case, the liquids are heated separately.

Advantages: rational energy consumption, work on natural draft.

Disadvantages: slow heating, the formation of limescale, the need for magnetic filters.

Specifications

The power range of wall-mounted equipment for thermal energy ranges from 4 to 60 kW. However, the most in demand are hinged boilers of low power - from 4 to 25 kW.

Devices differ in the type of burners, which are closed (turbocharged) and open (atmospheric). In the latter, air from the room is used for combustion, exhaust gases are discharged through a chimney with natural draft. In the first, air is taken from the street, gases are discharged into the street. A boiler with a closed burner can be equipped with two nozzles or a coaxial pipe - a structure made of pipes of different diameters, where the smaller one is inserted into the larger one. They are led out from the wall. Closed boilers are noisy because their operation is provided by a supply fan, but are considered safer.

In severe frost, the coaxial pipe can freeze, so its outer part is insulated with a protective casing.

Gas attachments are classified according to the principle of operation as conventional and condensing. In traditional boilers, the heat energy of the residual gases is not used in any way. Another heat exchanger is installed in condensing units to extract heat from exhaust gases. The combustion products are blown in by a fan. First, the coolant is heated by the heat of the exhaust gases, then it enters the primary circuit, where it picks up the required temperature. The efficiency of condensing boilers is higher than that of traditional boilers, but the price is also higher, since the device is more complex.

By the type of energy consumed, boilers are:

- Non-volatile - less functional, but more reliable. They work in houses and premises without electricity. Independent of power supply and voltage surges.

- Volatile - electricity is used as an additional source of power. When the power is turned off, the boiler does not work. It is recommended to connect them through a voltage stabilizer.

Volatile boilers are equipped with additional sensors and systems that increase operational safety.

Advantages and disadvantages

Each model has its own characteristics. Equipment is in high demand for a number of reasons:

- no need for a separate boiler room;

- compactness;

- autonomy;

- high efficiency;

- efficiency in comparison with devices operating on other types of fuel;

- the ability to connect to a gas cylinder and mains;

- simple operation.

There are also disadvantages:

- low power;

- dependence on electricity, sensitivity to voltage surges and the need to install an RCD for volatile models;

- an installation permit is required.

The heating medium for gas wall-hung boilers must be of high quality.

Features of connection and operation

A wall-mounted boiler of a simple modification can be installed independently if the manufacturer notes this possibility in the technical documentation. In any case, the connection to the gas main and the verification of the correct installation must be carried out by an authorized specialist. It is allowed to independently connect the device to the heating system, water supply. After checking the correctness of the installation, a specialist of the gas service will issue a permit to operate the boiler. You cannot use the boiler without this document, otherwise the owner will face fines.

Before installing the boiler, it is necessary to develop and approve a project for laying gas pipes and connecting equipment. After the approval of the project, the boiler is installed, strictly observing all the requirements of the project documentation.A meter and a shut-off valve must be installed on the supply pipe.

The room where the device is installed must have a window with a window. The wall on which the installation is carried out must be finished with non-combustible materials. Measures should also be taken to increase the efficiency of the ventilation system in order to ensure sufficient air exchange and minimize gas pollution in the room. It is recommended to make a hole in the kitchen door with an area of at least 0.02 m2 and close it with a grate.

Boiler selection criteria

The power of the device is the main characteristic that you should be guided by when choosing equipment. It is indicated in the technical documentation. If you do not make accurate calculations, it takes 1 kW to heat 10 m2 of space. These values are very approximate. By default, the ceilings in the room should be no more than 3 m high, there is only one outer wall - the one with the window.

The buyer should pay attention to the characteristics of the boiler, its additional functionality in the form of built-in control and safety systems, as well as to the initial conditions in which the equipment will operate:

- the presence of a chimney;

- the need to install a boiler for water;

- the quality of double-glazed windows and wall insulation;

- place of installation;

- budget;

- climatic zone;

- the location of the premises, relative to the cardinal points.

All selection criteria are interrelated and interdependent.

With more accurate calculations, it usually turns out that the boiler power should be 20-30% higher. In addition, it is necessary to provide for a power reserve in the event of severe frosts of about 20%. If an indirect heating boiler will be connected to the device, it is necessary to add about 30% more.

High power does not mean that gas consumption will be significant. This only suggests that the heated area will warm up faster. Fuel consumption in this case will be about the same as when using less powerful models.

Double-circuit boilers are more suitable for heating premises of a relatively small area - up to 250 square meters. If the total heated area is larger, there is a risk that the equipment will not cope with its task. In this case, it is recommended to choose a single-circuit hinged boiler, and to install an additional boiler to heat the water.

When purchasing a double-circuit boiler, you need to focus on the performance of water heating. The liquid is heated in a flowing manner, therefore this characteristic is fundamental. The manufacturer indicates the number of liters per minute when heating water at 25 or 35 degrees (Δt °). The norm for the simultaneous operation of one or two water points are Δt ° indicators:

- 25 ° C - 11 l / min;

- 35 ° C - 7-8 l / min.

In summer, cold water is much warmer, therefore, it does not need to be heated much; in winter, heating should be more intense.

Popular manufacturers of wall mounted gas boilers

The range of wall-mounted gas boilers is represented by products of foreign and domestic production, which differ significantly in price, quality, reliability. Models of boilers from German companies are considered to be of the highest quality:

- Vaillant;

- Bosch;

- Buderus;

- Wolf.

More affordable, but also reliable boilers from Italian manufacturers:

- Ariston;

- Beretta;

- Baxi.

Among the brands of domestic production, the most popular are "Neva", "ZhMZ". In any case, you should give preference to the products of those companies that have been on the market for a long time, provide a long warranty and have a developed network of service centers.

Reliability rating

In the first place in the rating of gas boilers is the Ariston brand. The company's products are represented by four lines, of which two - Alteas X and Ariaton Genus - belong to the premium segment, and two - Ariston Clas and Ariston Egis - to the middle one. The boiler can be purchased at a price of 25 thousand rubles.

In second place is BAXI. Particularly noteworthy are the compact models Baxi Main 4 and Main 5, Baxi Eco 4 and Baxi Eco Compact with an additional stainless steel heat exchanger and the budget Baxi 4 Tech and Baxi Eco 4S.

In third place are expensive but high-quality Vaillant units. Vaillant turboFIT VUW 242 / 5-2 is popular - this is a relatively inexpensive model from the two-circuit gas boilers with a copper primary heat exchanger declared in the rating.

The wall-mounted gas boiler is convenient in that, with all its functionality, it does not require a separate room for installation. Its rather modest characteristics are quite enough for heating and providing hot water to an apartment or a small house. Such equipment should be chosen taking into account the operating conditions, having performed the necessary calculations.