To create a heat supply system, it has become more common to install electric boilers for heating a private house for 220 V. They are much safer than gas units and have a number of advantages. Electric boilers can be used to heat residential, public and commercial buildings. They do not depend on natural fuel supplies. Such units are classified as environmentally friendly heat and power equipment, since they are not sources of emissions of pollutants into the atmosphere.

- Criteria for choosing an electric boiler

- Building type

- Boiler price

- Stability of electrical networks

- Separation of boilers according to the installation site

- Floor standing

- Hinged

- Boiler models by design

- Heating elements

- Electrode

- DIY installation and installation

- Connection to the heating system

- Advantages and disadvantages

Criteria for choosing an electric boiler

The thermal power of electric boilers belongs to the main indicator and is measured in kW. It characterizes the amount of heat consumed to heat water in the heating circuit in order to maintain the sanitary temperature of the indoor air in the room. This value should compensate for the loss of thermal energy in the heated rooms, and in the case of installing double-circuit boilers, ensure the operation of the DHW system. At the same time, it is necessary to buy a 220 V electric heating boiler with a small power reserve in order to compensate for the drop in the efficiency arising from voltage surges in the power grid.

Building type

There are single-circuit and double-circuit electric boilers. The difference lies in the additional functions of the second circuit for DHW heating. The simplest modifications are supplied only with a built-in tank and heating elements, and more complex designs of a double-circuit wall-mounted electric boiler have an expansion tank and an electronic control unit with protective functions.

Boiler price

The cost of an electric boiler is most influenced by the level of equipment. The more functions the boiler has, the higher the cost. Premium electrical modifications of boilers have an expansion tank that compensates for the expansion of water in the internal circuit during heating and a pump for circulation of heating water.

The assembly includes safety and regulation units that guarantee the protection of the unit and the heating system from overheating and overpressure. Without them, the boiler is much cheaper, but since they are needed technologically, they will still need to be bought. As a result, an electric boiler with the maximum configuration comes out cheaper than the budget option, which requires the purchase of additional boiler equipment.

Stability of electrical networks

Despite the fact that this performance parameter does not directly affect the design of a 220 V electric boiler for heating in a private house, it must be taken into account when choosing devices. The use of a single-phase 220 V power network allows the installation of electric boilers only with a capacity of up to 12 kW.

To ensure the stability of the electrical equipment, it is necessary to choose the correct cable cross-sectional area. This parameter is selected based on the loads and recommendations of the manufacturer.

Separation of boilers according to the installation site

Electric heat generators are divided into two types, depending on the housing design: floor-standing and hinged.

Floor standing

The boilers have maximum power, large dimensions and an additional circuit for hot water. They are installed as the main source of heat supply and can be paired with external hot water storage tanks. Main advantages:

- the ability to provide heat to individual houses with an area of more than 200 m2;

- high-speed heating of hot water.

The efficiency of such a heat supply system will depend on the use of differential metering of electrical energy and the level of thermal protection of the building.

These modifications have several disadvantages:

- high consumption of electrical energy for heat generation;

- the need for an isolated room for placing boilers;

- the need for a separate power line.

When installing a floor-standing boiler, all the requirements of the manufacturer and the current state standards for the safe operation of electrical equipment must be met.

Hinged

Electric boilers are designed for heating summer cottages and small individual houses. Sometimes they are used in schemes of backup or additional boiler equipment, which is put into operation when the main one, for example, a solid fuel boiler, fails.

The main advantages of mounted units are:

- insignificant specific electricity consumption for heat generation;

- compactness and small size;

- there are no restrictions on the place of installation.

The disadvantages of this design include low power and low level of equipment. The owner will need to purchase many auxiliary components of the heating system on his own.

Boiler models by design

Depending on the method of heating the coolant, electric boilers are electrode, induction and heating elements. Which type to choose for installation in the house will depend on the preferences of the owner, the possibilities of in-house wiring and the availability of free space for equipping the boiler.

Heating elements

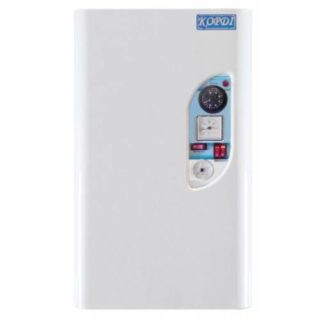

This is a traditional type of 220 volt electric boiler. In it, the hot medium is heated by heating elements made of a metal tubular body, inside which a nichrome spiral is laid. The distance between it and the body is filled with a dielectric material, which is usually quartz sand. The boiler can have one heating element or several, depending on the power and heating circuits. Such a device works on the principle of an electric kettle.

Electrode

These devices use water ionization technology. For effective heating, such devices need water that has undergone specialized training. Depending on this, the amount of electricity required for heating will change. Such devices require a solid grounding loop.

Induction electric boilers have a complex heating system and a high price. The installation of a large number of functional units will require a separate room. Such a unit uses the principle of a transformer and is made of primary and secondary windings. After starting, the primary, consuming electrical energy, creates a magnetic field on the secondary winding. The ferromagnetic core heats up and transfers thermal energy to the heating agent of the heating circuit.

DIY installation and installation

Initially, before installing the electric boiler, an installation marking is made in the selected place. When placing a floor-standing device, a fireproof metal sheet is installed on the surface. For wall modification, the installation site is protected with non-combustible building materials, then factory mounting elements are fixed on the wall, for which holes are made. In the process of work, the horizontal position of the installation is checked using a building level.

When connecting an electric boiler to the mains, grounding is carried out. Some boiler configurations will not start at all without a ground loop. The wiring from it leads to an individual RCD machine, to which an electrical outlet is connected to turn on the heating device. The manufacturer indicates the smallest square area of the cable cross-section in the annotation for the use of the equipment. The electrical wires are supposed to be hidden in the cable channel. After completing the piping along the electric line, the boiler casing is installed in place, the power is connected and the operation of the electrical components is tested.

Connection to the heating system

After installing the boiler and checking the functioning of the power supply system, the unit is connected to the existing indoor heating and hot water supply networks.

The heating element boiler, in the body of which there is a pump for circulation of heating water through the circuits, is connected to the system in this way:

- The supply and return pipelines are connected to the inlet nozzles using ball valves with "American" valves.

- On the return line in front of the boiler, a mud filter is mounted, in front of which a ball valve is cut in for ease of cleaning, and an expansion tank with a membrane operating principle.

- After installing all the auxiliary equipment, the necessary fittings and primary sensors for the temperature and pressure of the heating medium, the water circuit is pressurized. The heating circuit is filled with purified water and the system is tested for strength and leakage.

The increased pressure required for the pressure test is indicated by the manufacturer, it is pumped by a compressor or pump.

Advantages and disadvantages

The main advantage of heating electric boilers in comparison with other types of heating is considered to be their environmental functions and environmental safety. They work almost inaudibly, and therefore it is allowed to place such equipment inside the house. At the same time, electric boilers equipped with a control unit are capable of operating in automatic mode. They do not need the arrangement of smoke ventilation systems, which significantly reduces the overall cost of installation work.

An electric boiler with a single-phase connection has one significant drawback - it is an expensive type of heating. Even a high plant efficiency of 98% cannot compensate for the high energy costs.

Electric heaters integrate well with unconventional energy sources such as sun, wind and heat pumps. This significantly reduces heat generation costs and makes them competitive energy efficient sources.