Izospan is a type of vapor-permeable membrane. Passing steam in one direction only. If the material is installed correctly, it protects the insulation from moisture, if not, the heat insulator will get wet. Which side to put Izospan A on the insulation depends on its structure.

Izospan A, B, C, D - general information

Izospan is a large group of nonwovens and films. Its purpose is to prevent steam from passing to insulating structures, walls or roofs, but not to prevent moisture from evaporating from the side of the insulation. This is its difference from waterproofing, which does not allow moisture to pass in either direction.

There are 3 groups: windproof membranes that protect against moisture, hydro and vapor barrier films, vapor insulators that retain heat - foil. A more conventional classification divides Izospan into groups A, B, C, D.

Izospan A protects the material from moisture and wind coming from outside, but at the same time does not interfere with the removal of moisture from the insulation layer. The outer side of the membrane is smooth, repels water, the inner side is rough. In the pie, the membrane is placed in front of the insulation from the side of the roof so that water and moisture from the outside air do not penetrate into the heat-insulating layer.

Modification A applies:

- when insulating slopes with an angle of inclination of more than 35 degrees;

- for vapor barrier of frame walls;

- when cladding facades with siding or clapboard;

- as a windbreak under a ventilated façade.

Izospan B - vapor barrier film, used only for interior work. It is a two-layer material with a smooth outer surface and a fleecy inner surface. Unlike modification A, this option does not allow not only steam from the air to pass through, but also condensation that forms when there is excessive humidity in the attic or indoors.

Vapor barrier B is used:

- when arranging floors - mandatory when installing wooden and wood-containing coatings like slats, boards, laminate, parquet;

- when installing pitched and flat roofs;

- to protect any floors of the house - basement, interfloor, attic;

- for insulation of structures in the room.

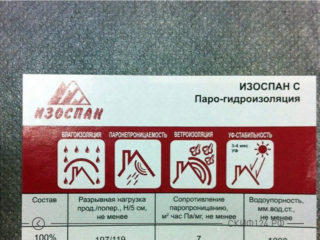

Izospan C is a type of hydro and vapor barrier membrane. Its difference is its increased density. The modification is used for vapor barrier of wooden structures - ceilings, walls, floors. When arranging a concrete screed, the membrane can be put in place of the waterproofing film.

Izospan D - the polypropylene base is laminated on one side. The material is very durable, has increased water resistance. The application is varied:

- to protect wooden roofs;

- when arranging the basement;

- when installing a concrete screed;

- as a temporary roof overlap or protective wall. This design lasts 4 months;

Izospan with lamination with kraft paper reflects heat radiation. It is used for the vapor barrier of baths and saunas.

The brands FB, FD, FS and other models from the group of foil-clad membranes not only vaporize walls or roofs, but also retain heat.

All types of Izospan are made from polypropylene. It does not cause allergies, is safe for health and is not susceptible to the action of fungi.

Material specifications

To find a suitable option, many parameters of the film are evaluated. The stronger it is, the longer it will last, and the more difficult it will protect. The higher the vapor permeability, the faster moisture trapped in it will be removed from the insulation.

| Material | Density, g / sq. m | Water vapor permeability, g / sq. m / day | Water resistance, mm. Water. st | Temperature range, С |

| Izospan A | 70 | 22,4 | 330 | -60–+80 |

| Izospan B | 90 | 18,4 | 1000 | -60–+80 |

| Izospan C | 105 | 3,7 | 1000 | -60–+80 |

In each specific case, additional qualities may be required from the material. Modification A with OZD belongs to the 1st class of flammability, since it contains fire retardant additives. Option B is used only inside the building. The group C vapor barrier has the same purpose, but due to its high strength, it is used in loaded areas. Its cost is 50-60% higher.

Assortment overview

Each group of materials includes modifications with different structures. The mechanism of action of all membranes of one group is the same, but the structure and properties are different.

The Izospan A line includes:

- A - its maximum vapor permeability at a higher density - 110 g / sq. m. When laying it, be sure to leave a gap for ventilation.

- AM is a three-layer membrane. It is installed without a ventilation gap: air passes between the layers of the vapor barrier and removes moisture.

- AS - has the same properties as the previous modification, but is denser - 115 g / sq. m.

- AQproff is a vapor barrier with a three-layer structure and reinforced reinforcement. Designed for external work. It is also used as temporary protection of a wall or roof for a period of time, while the main finish is absent.

- A with OZD - fireproof vapor barrier. A non-flammable membrane is installed when insulating ventilation facades. Also, A with OZD is used during welding to protect insulated structures located near the working area.

Izospan B and C are varieties of a vapor barrier with an anti-condensation film. Their purpose is the same and they differ only in strength.

Features of the correct laying of Izospan A to insulation

Which side to put Izospan to the insulation depends on its type. Materials of group A work on the principle of a check valve: they release air and steam, but do not let anything in. To protect the heat insulator, such a membrane is laid with its "front" side facing the street.

The sides of the membrane should not be confused. The front one is smooth, water-repellent, facing "the street", the rough inner one is turned towards the insulation. Sell material in rolls. It is cut into wide strips and overlapped by 15 cm.

When laying Izospan, a gap is left between it and the thermal insulation. If they take the AS or AD brand, the gap is not made.

During installation, the film must be stretched. Otherwise, with gusts of wind, it will hit the surface and be damaged.

Laying Izospan B

The smooth side of the film does not allow water to pass through, while the rough side absorbs condensate and evaporates it back. Izospan B is placed on the inside of the insulation or roofing cake. The smooth surface of the membrane faces the insulation, the rough surface towards the room. A ventilation gap is left between the vapor barrier and the trim.

Lay the film in wide strips with an overlap of 10 cm.

Laying Izospan C

Its principle of operation is the same as that of the previous vapor barrier: a smooth surface to the insulation, a rough surface to the finish.

Pros and cons

Vapor barrier membranes are a more reliable way to protect structures and insulation from moisture. Ordinary waterproofing film does not allow air and steam to pass in both directions. When placed outside the insulation, it protects against water entering from outside. However, it is powerless against condensation from indoor air.At the same time, it is impossible to waterproof the insulation on both sides.

Izospan allows steam to pass from the heat insulator, but protects it from the outside. This protection mechanism provides many advantages:

- No steam, condensation or moisture gets into the heat insulator. Dry insulation lasts much longer.

- Walls, roofing, frame structures protected from steam do not deform, do not rot, do not become moldy.

- Izospan serves as a wind barrier - it prevents the penetration of cold or humid air.

- The film is lightweight, elastic and durable. The installation of the vapor barrier takes a couple of hours.

- Izospan is made from polypropylene. It is a recyclable plastic that is more environmentally friendly.

The disadvantages of the product include:

- in conditions of high humidity, during rain or fog, installation is prohibited;

- before laying, the material must be kept in a warm room for a couple of hours;

- the cost of Izospan is higher than that of a conventional film.

The vapor barrier membrane is selected taking into account the purpose of the structure. Foil-clad material is taken to isolate the bath, Izospan of group A is chosen under the ventilated facade.

Features of protection with Izospan

Any building structures are insulated with a membrane. Each such work has its own characteristics.

Flooring

A vapor barrier film is laid on top of the insulation layer in one direction with an overlap of 15–20 cm. The material is brought onto the walls by 10 cm. The smooth side of the membrane faces the insulation, while the rough side faces the outside. If using the foil version, put the shiny side up. Seams and gaps are glued with adhesive tape. If necessary, fasten with construction brackets.

Izospan is also used as waterproofing - it is laid on the subfloor under a layer of thermal insulation.

Ceiling

Ceiling insulation refers to interior work. Izospan B is suitable for this. If the work is carried out in a sauna or bath, modification D is used.

A vapor barrier is required when laying soft insulation. If the concrete ceiling is treated with bituminous mastic, there is no need for it. Fix the membrane with the smooth side to the heat insulator and rough outwards.

The wooden ceiling is insulated regardless of whether there is insulation or not. The placement is the same: smooth surface inward, rough outward.