The construction market offers a huge list of materials used for flooring, including insulated linoleum. This is a rolled multilayer product that has a foamed or warm base, a wear-resistant layer and a top decorative coating. Thickness and stiffness vary depending on the composition and strength class of the product. The products are used mainly in residential buildings, apartments and summer cottages, especially in premises where, for whatever reason, it is not possible to install a warm floor.

Advantages and disadvantages

The advantages of using this material include the following properties:

- Decent indicators of thermal insulation: the surface heats up quickly, keeps heat well, so it is comfortable to walk on the floor.

- Possibility of laying both on a concrete or wooden base.

- The material masks surface defects, including cracks, chips, uneven areas.

- If you lay linoleum with insulation, you can further improve the thermal insulation parameters of the room.

- The texture is pleasant to the touch, making it comfortable to walk on the surface even without shoes.

- Environmentally friendly composition, absence of toxic components, which makes it possible to lay in a children's room.

- Good sound insulation performance, especially in varieties, the basis of which is made of polyvinyl chloride, foaming the material.

- A huge list of textures and colors. On sale you can find monochromatic linoleum of various colors, options with a combination of tones, geometric patterns, imitation of stone or wood.

The level of strength is not very high, and the material is also sensitive to moisture, especially if it is a variety with a pile. For this reason, it is not recommended to lay warm linoleum on a cold floor in rooms with high traffic, in bathrooms, kitchens, bathrooms and hallways.

Types of products

There are several types of flooring, differing in composition and basic characteristics.

Warm backing

The base is made of jute or felt, the top coating is a polymer film up to 1.5 mm thick. Linoleum provides good insulation, has an elastic structure; during installation, it is enough to lay it on the base without using glue. The disadvantage of such a coating is the reduced strength. A product with a warm backing is suitable for bedrooms, private rooms and other rooms with low traffic and a minimum amount of heavy furniture. In addition, jute or pile material is more sensitive to moisture, from which fungus and mold grows inside.

Foam-based

Linoleum with a base of foamed polyvinyl chloride has the following advantages:

- Increased mechanical strength, wear resistance.

- Practicality, minimal maintenance requirements.

- UV resistance: the surface is almost non-fading in the sun.

- Extended service life.

Thick linoleum insulated with foamed polyvinyl chloride has a base up to 3 mm, making up half of the total thickness, it is not so sensitive to humidity and is suitable for rooms with medium and high traffic - corridors, living rooms, offices.

Material features

To decide which linoleum is best for an apartment, with or without insulation, you need to pay attention to the technical parameters of the products. There are many varieties on sale, differing in structure, degree of strength, design and price.

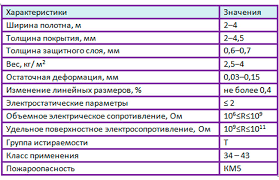

Characteristics

Depending on the type of product, insulated linoleum has a total thickness of 0.7-4.5 mm, the protective layer is 0.2-0.5 mm. Semi-commercial and commercial varieties are stronger and thicker, but more expensive. The base can be made of PVC, felt, jute, and other components of predominantly natural origin. According to the degree of wear resistance, the material can be used for household, office and industrial premises. The first category includes classes 21-23, the second - 31-34, and the third - 41-43 class goods.

Life time

The service life also varies depending on the class and purpose. On average, insulated linoleum retains its quality for up to 10 years. Commercial varieties used in residential settings can last up to 12-13 years. With increased traffic of the room, the coating will fade faster and will require replacement.

Moisture resistance

Natural varieties with a felt or jute base are less resistant to moisture; when used in a bathroom or kitchen, linoleum will quickly become moldy. This material is optimal for children's rooms and living rooms. The variety with a PVC base is more resistant to water and other liquids, so the products can be laid in rooms with high humidity.

When buying insulated linoleum, you need to pay attention to many additional characteristics. It is necessary to compare the offered products in terms of the degree of resistance to abrasion, mechanical stress, including point and directional. It is necessary to look at the level of color fastness, the class of flammability, the degree of safety. It is important that the goods are issued with certificates of compliance with fire requirements and GOST standards.

Choice for an apartment

To choose linoleum for an apartment, you need to consider the following factors:

- Appointment of the premises. If the room is not inhabited, it is not always advisable to lay such a floor covering. If the building is not heated or the heat loss is high and costs need to be reduced, pile linoleum can be used.

- Heating quality. When using weak equipment, the use of insulated flooring will bring little benefit.

- If the room has a high temperature humidity, you need to choose a material based on artificial components.

It is important to consider the compatibility of shades and patterns with the design of the rooms, as well as the color scheme of the entire room.

Styling features

Before installation, it is required to prepare the base: it is cleaned, repaired, repairing cracks or chips, if any. Installation is carried out indoors at temperatures above 18 degrees Celsius. Special glue is used for fastening. It is required to coat the wrong side around the perimeter and evenly across the width, this will ensure maximum adhesion.

If the coating is laid on a concrete floor without infrared heaters, the felt variety is usually used. For additional thermal insulation, it is required to lay an interlayer of foam foams. Thanks to this, heat loss will be lower.