Welding heating pipes is the main method for assembling household and industrial communications. Connections of this type do not require any maintenance, like glued or threaded joints, but they are subject to constant thermal and mechanical stress. Based on this, you need to carefully select tools, materials and carefully observe the technology of welding. Violation of the rules for joining metal leads to the appearance of cracks and the development of corrosion. If you plan to do this procedure yourself, you should figure out what methods are used to weld heating, as well as professional techniques to achieve a high-quality and durable result.

Set of tools and equipment

Welding heating pipes with electric welding begins with the preparatory stage:

- Preparation of the master. It is necessary to properly equip the workplace, ensure compliance with safety measures, if necessary, re-read the instructions for handling equipment and materials. To weld pipes with electric welding, protective devices will be required. These include a special fireproof suit (pants, jacket, hat with livery), mask, shoes and leggings. You need to take care of good ventilation.

- Preparation of tools and materials. Attention should be paid to every little detail, since the convenience of work and the quality of the final result depend on it.

To weld heating, you need the following tools and devices:

- welding machine with a spare holder;

- grinder with cutting and grinding discs;

- metal brush;

- sandpaper of different grain sizes;

- a hammer;

- stock of electrodes;

- vice;

- clamps;

- steel or asbestos-cement sheets to protect walls from metal drops and soot;

- a tarp to cover the flooring.

Before welding pipes with electric welding, it is necessary to check the compliance of the cables, sockets and machines in the shield with the indicators of the prepared apparatus. They have to be powerful enough to withstand the heavy loads that even household equipment imposes.

Plastic pipe welding technology

Polypropylene is gradually replacing steel, since it has a number of positive characteristics at a relatively low cost. Plastic piping is designed for high pressure, lightweight, smooth inner walls and excellent appearance. But the pipeline will perform its functions effectively if all joints are strong and tight. It should be borne in mind that when hot water is passed with a temperature of over 110 degrees, the polymer becomes soft and begins to increase in size. Therefore, for the installation of heating, only products reinforced with fiberglass or aluminum foil are used.

A special soldering iron is used for joining the links. The device is double-sided, on one edge there are nozzles for the external, and on the other - for internal heating of the joined parts.

To connect them, the following fittings are used:

- couplings;

- adapters;

- corners;

- tees;

- crosses;

- threaded flanges for connection to the heating battery.

When soldering polypropylene communications, the principle of diffusion under the influence of heat is used.The edges of adjacent links melt, the substance mixes and forms a monolithic compound.

The process of welding polymer parts is carried out according to the following method:

- Drawing up a piping diagram for the heating system.

- Sawing workpieces of a certain length. Correction is made for the amount of immersion of pipes in the holes of the fittings and the dimensions of the fittings themselves.

- Warm up the soldering iron until the green indicator lights up. This is evidence that assembly can begin.

- Attachment of parts to the device on the branch pipes of the corresponding diameter. They need to be heated in accordance with the indications of the table with which the equipment is completed.

- Pipe and fitting connection. This is done strictly in one direction, until the inner part rests against the locking tab in the fitting. You cannot rotate the products, move them back and forth. Correction for the joint angle is allowed.

- Cooling. It is necessary to maintain the joint in a static position for as long as prescribed in the instructions for the device. Only then can the assembly continue.

Unlike metal pipes, polymer pipes need support for vertical and horizontal purlins. Every 100-150 cm they are fixed to the walls with plastic spacer clamps. After assembly, polypropylene communications do not need additional finishing and subsequent maintenance.

Metal pipe welding technology

In order for the connection to be strong and tight, it is necessary to prepare the system parts before installation. It is necessary to check the evenness of the edges, chamfer and grind the metal at a distance of 10 mm from the cut. After that, you need to treat the cleaned places with a solvent in order to degrease them.

To weld pipes for various purposes, electrodes with the following coating composition are used:

- rutile acid (RA) - for the installation of cold and hot water supply in the public sector;

- rutile (RR) - for the assembly of heating systems operating under high pressure;

- rutile cellulose (RC) - used in structures requiring high reliability of joints;

- universal (B) - for the assembly of all types of pipelines in the residential sector and in production.

You can cook metal pipes using the following technologies:

- Electric welding. It is carried out manually or using a machine. The principle of operation is based on the creation of an electronic arc that occurs during a short circuit. This process is accompanied by the release of a large amount of heat, causing the metal to melt. Consumable or non-consumable electrodes are used to create a seam.

- Gas welding. The pipe joints melt under the influence of the burning gas, simultaneously with the imposition of a metal on it, which acts as a coupling. A monolithic joint is formed, which has a homogeneous structure with adjacent parts.

- Cold welding. This method is used when installing low pressure pipelines or repairing them in hard-to-reach places. The essence of the method consists in wrapping a bandage impregnated with a quick-setting adhesive around the knock.

The choice of the option is correct if it corresponds to the characteristics of the system and the characteristics of the coolant.

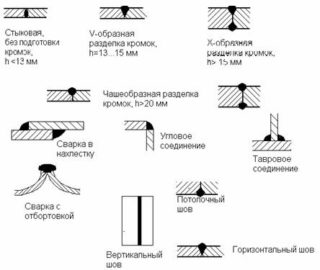

Classification of welds

The joint can be welded in different ways based on the design features and the thickness of the metal being processed.

There is such a classification of welds:

- In appearance, they are flat (normal), weakened (concave) and reinforced (convex).

- By length - solid (continuous, closed), discontinuous (dots, segments). In terms of length, the seams are subdivided into short (up to 25 cm), medium (26-100 cm) and long (more than 101 cm).

- On execution - horizontal (on vertical sections), vertical (on horizontal runs), ceiling (when the joint is made from below), bottom (electrode on top of the seam).

- According to the effective force - flank (along the axis), frontal (across the axis), oblique (across), combined (combination of types).

- By the number of layers and passes - single-layer (one pass) and multi-layer (several passes).

With the correct installation of the heating system, all of the listed seams can be performed. If necessary, welding is also carried out on the inside of the pipes.

The main types of welded joints

According to their location in space, the seams are divided into the following types:

- angular - parts are at an angle;

- T-shaped - connection of the end and side of the elements;

- butt - pipes are connected in one plane;

- overlapping - parts are superimposed on each other;

- end - the abutment of the lateral surfaces of the fragments.

In the course of work, the master chooses the most convenient for himself and corresponding to the technical conditions method of welding parts.