To maintain performance, flushing and pressure testing of the heating system should be carried out regularly. This is done by specially trained people. The process itself is regulated by regulatory documents. To prevent leakage detection, the pipes are pressurized with a pressure exceeding the working pressure in the heating system.

What is flushing and pressure testing of the heating system

Works for the preparation and resumption of the uninterrupted functioning of the heating guarantee the trouble-free flow of the coolant.

Flushing

If the batteries in the apartment begin to heat up worse than before, there are several reasons:

- poor boiler performance;

- breakdown of the pump;

- airing pipes.

During many years of operation, debris, scale particles, and rust accumulate in pipes, heating devices, collectors. Growing up inside, they clog the passage hole for the coolant, the porous structure reduces the heat capacity of the metal parts of the heating devices.

Consequences of blockages:

- burnout of the heat exchanger, requiring its replacement;

- temperature difference in batteries;

- noise in the pump with subsequent failure;

- boiler breakdown.

To eliminate, prevent contamination, flushing is performed.

The decrease in heating efficiency occurs for 2 main reasons:

- The appearance of mineral deposits. Non-galvanized pipes willingly accept calcium and magnesium salts on the surface. With galvanized pipes, such problems do not arise.

- Sludge growth in pipe sections with a low speed of movement of the coolant. Multi-section cast iron radiators are susceptible to this phenomenon. The dependence is proportional to the increase in the volume and number of sections.

People carry out flushing of simple appliances and heating pipes in private houses on their own. It is easy to do with the knowledge and equipment. It is better to entrust heating systems and batteries in apartment buildings to professionals who are responsible for their work and give a guarantee.

There are 2 ways to clean the system:

- special hydropneumatic equipment;

- chemical reagents.

The basis of chemicals is acid.

Crimping

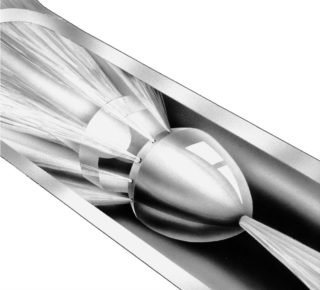

This procedure is designed to test the hydraulic system for weaknesses. The tests are carried out using the overpressure of the water circuit or by pneumatic method.

Equipment for work

CIP flushing of engineering heating systems with chemical reagents is carried out by an eliminator device with manual or automatic reverse. There are imported and Russian samples on the market, differing in the volume of pumping, the type of reverse and other functions. Work is performed with a washing reagent. Then the action of washing with a neutralizing solution is stopped. Electrical devices pressurize and expel the chemical solution.

For hydropneumatic cleaning, you need a pneumatic pump capable of catching up with a pressure of up to 6 atm. and higher.

The hand pump is a flask with a side-mounted plunger pump and a drive arm. Shut-off valves cut off the water after heating, others - for draining the coolant from the device. The plunger pump raises the pressure to 60 bar.The disadvantage when used in private homes is many hours of work with a large expenditure of muscle energy.

Professional washers use automatic instruments. They set the pressure limit, upon reaching which the automation turns off the unit. Professional models maintain a pressure of 40-100 bar. Industrial pressure testing stations deliver up to 1000 atmospheres.

Stages of crimping

The work is carried out with the following frequency:

- when starting a new system;

- annually after the heating season;

- after flushing or repairing the heating main with replacement of pipes.

For apartment buildings, the preparation is as follows:

- Inspection of valves in elevators, central pipes, risers. On cast iron valves, the glands are changed, the paronite gaskets between the flanges of the joints are renewed, and unusable bolted joints are changed.

- Pipes and fittings are examined by visual observation for cracks, chips, corrosion, and defects. Make repairs if necessary.

- Check the thermal insulation of risers, main pipes in basements.

Pressure testing procedures and testing are carried out taking into account the parameters of heaters, thermal equipment inside the premises. The standards allow the use of operating pressures up to 6 bar for cast iron radiators. When they are in the walls, the maximum is 10 bar.

Hydraulic tests are carried out as follows: the system is checked as a whole, then a pressure above the operating pressure is applied to the heating unit.

According to Rules 115, clause 9.2.13., Tests are carried out with a pressure not lower than:

- 1 MPa - elevators, heaters for heating and hot water systems;

- 0.6 MPa - cast iron and steel heating radiators;

- 1MPa - convector, panel heaters;

- working pressure plus 0.5-1 MPa for hot water supply;

- pressure recorded in the heater manufacturer's instructions.

The test pressure in steam systems is selected by the manufacturer from the maximum to the operating minimum:

- minimum - not less than 0.2 MPa, but not less than 1.25 working;

- the maximum is set by the strength calculation according to the norms;

Crimping takes place at a temperature of + 5 degrees. If negative - in case of emergency.

Stages of crimping:

- Filling the system with cold water. During work, the temperature of the liquid is not more than 45 degrees. The pressure rises gradually. Control is carried out using a pressure gauge.

- When the set pressure is reached, the system remains at rest for about 30 minutes.

- During downtime, an inspection is carried out for leaks in pipes, batteries. Make sure there are no smudges. The method of control is placing toilet paper in dangerous places or wrapping pipes with it. With leaks, spots of water and silt are visible.

- The control takes place according to the readings of the pressure gauge. Leaks happen in a place inaccessible to observation. A drop in pressure will warn about this.

At the end of the pressure test, an act of fitness for use is issued.

The tests are carried out by certified companies. It is forbidden to carry out heating work independently in apartment buildings. This is done by employees of operating organizations - housing office, management company, housing department, REU. They are required to undergo annual certification at MOEK.

Flushing heating systems

The accumulation of sludge, scale in pipes and radiators reduces the quality of heating - just 1 mm of scale reduces the heat transfer of the device by 15%. To normalize the temperature in the house, it will be necessary to increase the heat transfer of the boiler, and this is additional fuel and labor costs. Scale is inherently a heat insulator. Its thermal conductivity is 40 times lower than the metallic composition. Therefore, even a thin layer leads to a decrease in the heat transfer from the heat carrier. The scale is aggressive. It interacts with metal and leads to increased corrosion. The aggressiveness of scale creates fistulas for several years and eats away at welded seams.

In an apartment building

The hydropneumatic method of flushing the heating system is constantly used by workers of public utilities. If you follow the technology, this is an effective way.

The principle of operation is simple - first, water is discharged, then pumped back into the heating system. Under the action of the heat carrier flow, scale flakes are exfoliated and come out together with water when draining.

Step by step sequence:

- All taps are shut off before work.

- The end sleeves of the heating batteries are unscrewed using a special key.

- The return valve closes.

- The air pump is connected to the valve located after the valve.

- The return flow is reset.

- A pressure of over 6 atm is pumped into the pneumatics.

- The valve to which the pneumatic equipment is connected opens.

- Risers overlap in turn. Up to 10 pieces at a time - this will make the flushing procedure effective.

The next step is to put the system into dropping in the opposite direction:

- The discharge closes, the valve connected to the device closes, the pneumatics are turned off.

- An open valve slides in, after which a similar one opens on the return.

- Water is discharged - the pneumatic pump is connected through the valve in the opposite direction, the valve opens, the pneumatics turns on. The liquid will flow in the reverse direction.

The efficiency of cleaning is determined visually - if a clear liquid begins to come out, the flushing can be completed. Dirt is drained into cooked dishes. If possible, a hose is connected and the dirty coolant is discharged into the sewer.

In a private house

Washing in a private house is difficult to do with your own hands, but in reality, after reading the instructions. Produced in two ways:

- Flow-through method. Cleaning from slags and deposits in this way consists in completely filling all devices with a coolant with the air outlet valve left open. After filling, the valve closes. Simultaneously with the supply of compressed air, the drain hole opens. The water-air mixture continues to be supplied until clear water appears. The amount of flushing fluid is 3-5 times the working value. Therefore, prepare drain containers or drainage in advance.

- Flush with filling. The system fills when the valves are closed. Air is supplied under pressure for a period of 5-10 minutes. into the inlet pipe, while the outlet is closed. After the end of the compressed air supply, the flushing is drained together with dirt and scale.

The volume of the supplied liquid and air is calculated individually. Incorrect calculation will result in multiple pipe bursts rather than flushing.

In private houses, collectors, locking fittings, boilers, boilers, joints with devices, electric circulation pumps, warm floors are checked.

It is not necessary to buy flushing equipment - it is rented. If it is necessary to draw up official papers and a test report, a special team is called. The estimated cost of services is 1000-2600 rubles / hour.

Flushing and Pressure Testing Requirements

Pressure testing is carried out exclusively at a positive air temperature - above +5 degrees. When negative, it is allowed during the elimination of accidents. The tests are successful in such cases:

- no fogging of welding seams, leaks in heating devices - boilers, pipes, heating radiators, taps and other equipment;

- the pressure drop on the manometer does not exceed 0.2 bar in 5 minutes;

- in panel heating, the decrease in pressure gauge readings does not exceed 0.1 bar per quarter of an hour;

- in the hot water supply, the pressure drop of the coolant is below 0.5 bar in 10 minutes;

- for plastic pipes, the pressure drop in the system is below 0.6 bar in 30 minutes, for the next 2 hours - less than 0.2 bar;

- when testing with air pressure, a decrease in pressure is allowed up to 0.1 bar in 5 minutes.

Work on flushing and pressure testing of the heating system is regulated by special papers.

Section 9.2.12. strength and density tests, in accordance with the "Rules of technical operation" (PTE), thermal power plants from the Ministry of Energy of Russia. The types of tests are regulated - primary, periodic, extraordinary. According to the clause "Rules", the systems are flushed with the start of commissioning. Also, annually at the end of the heating period, after accidents, replacement of pipes or major repairs.

The calculated volume of the coolant must exceed the working volume by 3-5 times and be completely light at the exit. Rinse with industrial or tap water.

Commissioning an untested heating system is prohibited.

Flushing improves the circulation of the coolant and the heat transfer, cost savings, comfortable living.

Rule 115 clause 9.2.13. "Strength tests". In the requirements of tenders, the OKPD code of the 2nd category 43.22.12.120 for flushing and pressure testing of the heating system is assigned to the works:

- installation of heating equipment;

- installation and maintenance of central heating control systems;

- connection to district heating systems;

- installation and maintenance of household boilers and boilers;

- installation of ventilation, refrigeration equipment in residential and non-residential premises.

Does not include: repair and maintenance of industrial boilers, air conditioners, refrigerators, installation of solar collectors, baseboard heaters, cleaning of chimneys.

The test results are recorded in the test report for strength and density. If the results are unsatisfactory, the deficiencies, leaks are eliminated and the tests are carried out again.