The use of new technologies is a prerequisite for improving heating systems. This applies to innovative materials of manufacture and fundamentally different methods of obtaining thermal energy. Not the last place among the novelties is taken by electrode boilers for heating the house: the device, reviews about them will allow you to form an objective opinion about the appropriateness of the application.

Design features and types of electrode boilers

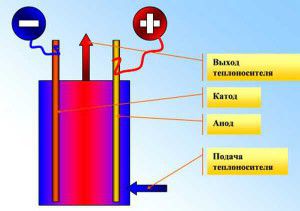

Electrode boilers for heating a private house work using the principle of the movement of electrons between two electrodes. As a result of this, the heat carrier is heated. In practice, this is feasible if several technical conditions are met.

The main one is the design features that distinguish electric electrode heating boilers from other similar system components. To create an appropriate response, the structure must include the following components:

- Hermetically sealed housing. Its outer surface must be isolated from the inner one to ensure operational safety;

- Electrode block. It will cut from the cathode and anode. When an electric current is applied between them, the heat carrier is heated;

- The system of supply and return pipes for connection to transport heating mains;

- The control unit through which the connection to the mains is made.

Such a device for an electrode heating boiler provides a relatively small size and weight of the structure. However, at the same time, it lacks the traditional elements characteristic of most models of gas boilers - an expansion tank, a circulation pump and a safety group. Therefore, reviews of electrode heating boilers indicate an increase in the labor intensity of arranging the system. It is required to correctly select and install these components to ensure the operability of autonomous heat supply.

A modern electric electrode heating boiler can differ both structurally and a set of functions. This must be taken into account when choosing models. So, the simplest one consists only of a housing with an electrode heating unit without additional components. But besides this, the consumer has the opportunity to choose from the following design options:

- Single or three phase... It all depends on the required power of the equipment. So, a home-made electrode heating boiler with a capacity of less than 9 kW can be connected from a single-phase network. If this parameter is higher than 9 kW, a three-phase network is required;

- Number of heating circuits... Some models can work both for heat supply and for hot water supply of a house or apartment;

- Control unit... With its help, the power is automatically adjusted depending on the water temperature.

It is noteworthy that household electrode heating boilers can only be used in closed systems. If there is no coolant in the area of its heating, equipment breakdown may occur.

It is best to make an electrode heating boiler with your own hands according to factory drawings of a similar design. Otherwise, there is a high probability of improper or dangerous operation of the equipment.

Installation and operation of electrode boilers

After selecting the boiler, it is necessary to correctly calculate its power. To do this, you can apply the traditional principle that 10 m² of the room will require 1 kW of electrode boiler power to heat a private house. But this method is effective only with a standard ceiling height and good thermal insulation of the room.

To install an electric electrode heating boiler, it is necessary to select its location correctly. Another advantage is its small size. So, one of the most common 6 kW models has a length of 335 mm and a diameter of only 25 mm. In this case, the weight of the structure is 1.1 g.

For full operation, in addition to knowing the device of the electrode heating boiler, additional components will be required. These include an electronic thermostat and an RCD unit. This will allow you to secure and automate the operation of the heating system.

Installation procedure for an electric electrode heating boiler:

- Read the instructions from the manufacturer.

- The diameter of the pipes to be connected to the heating pipes must match the corresponding boiler mounting assemblies.

- The direction of movement of the coolant is indicated on the body of the structure. It must match the actual one in the system.

- Select a heat carrier for electrode heating boilers.

The last point is very important, as the device will not work effectively with distilled water or antifreeze. It is recommended to use a special liquid with a high content of salts and additives. This will optimize the process of heating the coolant by creating additional electrical connections in the liquid medium.

For normal operation of household electrode heating boilers, it is necessary to connect to an emergency source of electricity. It will make it possible to heat the water for some time even after a power outage.

Overview of electrode boiler manufacturers

Despite the simplicity of the design, it is not recommended to make the electrode boiler yourself. This is due to the peculiarities of the manufacturing technology. To ensure normal operation, it is necessary to choose the right materials of manufacture, as well as perform a number of complex engineering calculations.

Currently, there are several manufacturing companies engaged in the production of electrode heating boilers for a private house at a professional level. They monitor the quality of their products, and provide warranty and post-warranty services.

Galan

The Russian production company "Galan" mastered the manufacture of high-quality electrode heating boilers back in the late 90s. During this period, new models were developed, which differ not only in power, but also in operational parameters:

- Hearth series... Designed for the organization of autonomous heating in a small house or city apartment. The power of these electric electrode heating boilers ranges from 3 to 6 kW. Those. they can be connected to a regular 220 V power supply;

- Geyser... Designed for heating large objects. The rated power can be from 9 to 50 kW. Connection only to a three-phase network.

In addition, the company offers a ready-made coolant for Argus-Galan electrode heating boilers. It contains the necessary components for efficient heating operation.

Stafor EKO

The range of products of this Latvian company is much smaller than that of Galan. However, its products differ in a positive way from even the best homemade electrode heating boilers. A novelty in the company's product line is a boiler with a built-in heat exchanger. It implements a different principle of water heating:

- An insulated part with a coolant exposed to the cathode-anode pair;

- The resulting heat energy is transferred to the water in the system.

This unique device of the electrode heating boiler can significantly increase the area of the heated room and increase the safety of heating in general.

The cost of boilers largely depends on their rated power, manufacturer and design features.

| Model | power, kWt | price, rub. |

| Galan Ochag-3 | 3 | 8200 |

| Galan Ochag-6 | 6 | 9660 |

| Galan Geyser-15 | 15 | 21060 |

| STAFOR 3-5 | 3-5 | 7980 |

| STAFOR 5-10 | 5-10 | 12540 |

Before purchasing, it is recommended to inquire about the nearest service point or brand service of a particular manufacturer. This is necessary not only for the prompt repair of a household electrode heating boiler, but also for obtaining timely advice on installation and maintenance.

Voltage surges can adversely affect the operation of the electrode boiler. The way out of this situation is to install a stabilizer.

DIY electrode boilers and reviews

You can make an electrode heating boiler yourself only if you have a factory heating block. He will determine the future power of the structure and its dimensions.

For manufacturing you need a piece of pipe with a diameter of 25 mm. This figure may vary depending on the size of the electrode assembly. A heating element is installed in the end part of the branch pipe and the hole is sealed. Then the connection to the system is carried out and the first test run of the equipment is carried out.

In practice, making an electrode boiler is problematic, since it is associated with the following difficulties:

- Insufficient tightness of the structure leads to the appearance of micro leaks;

- The actual power does not match the calculated one;

- There is no guarantee of normal operation of the equipment, the risk of its failure is increased.

In addition, the density of the heating medium for electrode heating boilers must be maintained at the same level. It depends on the brand of the boiler and the total volume of water in pipelines and radiators.

It is these factors that have caused a number of negative reviews about electrode heating boilers. If the rules for the installation and operation of the factory model of heating equipment are followed, the likelihood of problems is minimal:

- After purchasing the electrode boiler, we decided to install it ourselves. But after that the water was heated in jerks - it was impossible to heat the apartment. As it turns out, fine tuning is required after installation;

- It took a long time to decide which boiler to buy for a small summer cottage. We stopped at the electrode, as it is small and reliable according to reviews. Advantages: heats up quickly, no noise, reliable. The disadvantages include high electricity consumption. But this is common to all electric boilers;

- I strongly recommend to everyone who bought and installed an electrode boiler to use only proprietary coolant. Self-cooking with the addition of salt gradually destroys metal pipes and radiators.

Is it worth purchasing an electrode boiler for organizing heating? Currently, this is one of the most optimal options in the absence of gas pipelines. It is also ideal for heating a small house or city apartment.

In the video, you can see an example of a functioning Galan electrode boiler: