A plate heat exchanger is a type of recuperative heat exchanger, the principle of which is based on the conversion and movement of thermal energy from one medium to another, by means of contact plates. Collected in one bundle, they form a kind of channels through which the coolant moves. The parameters and dimensions of the device are indicated by the standards of GOST 15518-83.

Types of heat exchangers

Depending on the degree of accessibility to maintenance and inspection, heat exchangers are divided into several types:

- collapsible,

- brazed,

- welded,

- semi-welded.

Collapsible

Apparatus of this type are assembled and disassembled for periodic maintenance, inspection and repair. The heat transfer process is carried out by means of plates, which alternate with each other, forming two paths of movement. This eliminates the mixing of thermal energy between the two streams. All plates are separated by rubber spacers.

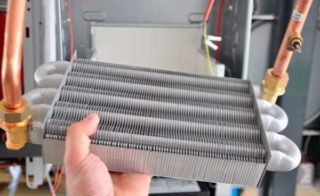

Brazed

Devices of this type are not disassembled, unlike the previously considered type, and all plates are soldered to each other. The advantages of such devices are considered affordable cost and small dimensions. The main area of application is domestic gas boilers and other heating systems.

Welded

Units of this class consist of plates welded together without rubber seals. The movement of the heat flow occurs through two channels: one along the corrugated, the second along the tubular. Among the disadvantages are the high cost of the device and its size. Heat carriers of this class are used on an industrial scale.

Semi-welded

A structure consisting of plates that are installed in a combined way. The seals are located on the outside of the welded plates in pairs. Such equipment makes it possible to use it in extremely aggressive environments or in cooling systems.

Advantages and disadvantages

Among the positive aspects of using such units are:

- lack of large production and investment costs;

- efficiency of heat supply;

- small size;

- self-cleaning ability due to high turbulent flow;

- by increasing the number of plates, it is possible to achieve an increase in efficiency;

- reliability;

- ease of maintenance and flushing;

- light weight;

- ease of installation;

- minimal surface contamination;

- complete elimination of mixing of different types of coolant, thanks to a special sealing system;

- corrosion resistance;

- high efficiency provides a minimum heat exchange surface;

- the ability to reduce pressure losses to a minimum by using plates with different types of profiles;

- temperature regulation.

The disadvantages of plate heat exchangers include:

- the need for grounding;

- exactingness to the quality of the coolant.

A large number of advantages allows the use of heat exchangers in the domestic and industrial segment.Demanding on the coolant is probably not a drawback, but a necessity, in order to prevent the frequency of replacing plates that have become unusable.

Plate heat exchanger device

The plate heat exchanger is widely used for heat exchange of vapors or liquids and acts as a cooler, preheater or condenser. It consists of several components:

- movable plate;

- fixed plate;

- branch pipes with threaded flange and welded connection;

- a set of plates fastened together;

- bottom and top guides;

- threaded stand for fastening and studs.

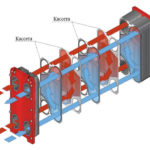

Rubber seals are located between the plates. The movement of thermal energy occurs according to several schemes:

- direct flow,

- countercurrent,

- mixed.

The selection of equipment for installation in the heating system and the calculation are performed using special software developed specifically for these purposes.

Connection diagram

To connect the plate TO, a classic scheme is used, in which the coolant inlet and outlet pipes located on the front panel are involved. Most often, these holes are positioned in such a way as to provide a counterflow of thermal energy and prevent mixing of hot and cold flows.

The second option for connecting the heat exchanger uses the same inlet and outlet nozzles, which can be located not only on the front panel, but also on the rear.

The connection of the input and output streams of thermal energy occurs by means of branch pipes with flanged, threaded or welded connections.

In some cases, no branch pipes are used. Then the connection takes place by drilling additional holes with an internal thread for the installation of studs, which will serve as an attachment of the coolant to the pipeline. As a gasket, you can take a heat-resistant rubber or rubber seal.

Selection rules

The choice of equipment depends on several parameters, each of which is calculated individually, depending on where the heat exchanger will be installed.

When choosing a model, you need to determine the following points:

- type of medium (steam, water, etc.);

- temperature indicators at the inlet and outlet of the coolant;

- allowable pressure loss;

- maximum temperature indicators;

- maximum pressure inside the device;

- thermal load on equipment.

After obtaining data on these parameters, it is necessary to calculate the indicators of the heat exchange system. After that, you can start choosing a model, based on the available power indicators, water flow rate, diameter and heat exchange area.

Principle of operation

The principle of operation of a plate heat exchanger cannot be called simple. The plates are installed at an angle of 180 degrees relative to each other. Usually this is a soldering of two pairs of plates that provide input and output of thermal energy. The extreme pair does not participate in the heat transfer process.

Depending on the design features, heat exchangers are usually divided into three types:

- single-circuit,

- multi-circuit,

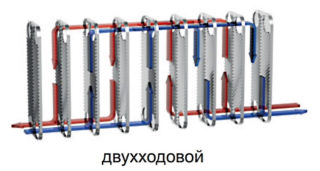

- two-way.

The circulation of thermal energy in a single-circuit device is carried out permanently, along the entire circuit and in one direction, with a simultaneous counterflow of the coolant.

The movement of the heat carrier in the multi-circuit equipment occurs in different directions. Such devices are used only if there is a slight temperature difference in the return and inlet flow.

The movement of heat energy in two-way devices occurs along two independent circuits, subject to constant control over the heat supply.

There is another type of device - a steam plate heat exchanger, which is responsible for heating water or other liquid in the heating system. The principle of operation of this device is no different from the standard models of plate aggregates.

Plates for plate heat exchanger

Steel, 1 mm thick, is used as the material for the plates. To turbulize the coolant flow and increase the heat exchange area, the flow part of the plates is ribbed or corrugated.

When viewed in section, the corrugated surface has an equilateral triangle profile. The resistance and flow rate depend on the degree of the angle at which the corrugation is located. The sharper it is, the lower the resistance and the higher the speed of the coolant.

In addition to steel, other alloys are also used for the manufacture of heat exchanger plates, depending on where the device will work.

Applications

Each type of heat exchanger has its own scope.

Gasketed heat exchangers are usually used:

- for the installation of heating networks;

- in refrigeration chambers;

- in pools, etc.

Brazed devices are used:

- in freezers;

- in air conditioning systems;

- in ventilation systems;

- in compressor installations.

Welded and semi-welded devices have found their application:

- in climate control and ventilation systems;

- in the pharmaceutical industry;

- in the food industry;

- in heating systems and hot water supply;

- in circulation pumps, etc.

In domestic use, a brazed type of heat exchanger is most often found. It is responsible for cooling or heating thermal energy.

A heat exchanger is a system element used in the utilities, food, metallurgical and oil and gas industries, as well as in shipbuilding. The prevalence of advantages over disadvantages indicates its effective use. Having correctly identified the technical characteristics and tasks of the device, you can install the heating system at home using the drawings and connection diagrams of the heat exchanger that are publicly available on the Internet.