The correct selection of the heating system ensures the comfort of living in a private house, allows you to save on utility bills. Open and closed heat supply systems provide effective heating, but differ in equipment, installation complexity and cycle of work.

- Features of open and closed systems

- Open system

- Closed type of communication

- The main differences

- System connection options

- Dependent way

- Independent way

- Features of pipe routing

- One-pipe method

- Two-pipe method

- Types of communications by type of circulation

- Natural circulation

- Forced circulation

- Installation rules

- Open system installation requirements

- Closed system installation procedure

- Independent organization of the heating system

Features of open and closed systems

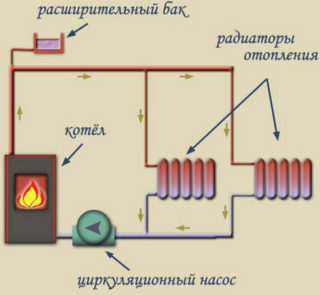

To heat the house, they use a closed type of design for the movement of the coolant, which includes a boiler, radiators and pipes. The system works on the principle of heating water to a certain temperature in special equipment, moving through the pipeline to the radiators and then releasing heat to warm up the rooms. After cooling, the liquid returns back to the heating device, forming a repeating cycle.

Open system

To understand what an open heating system is, it is worth using a multi-apartment type of building as an example. This type of heating involves the use of a special storage tank, which is actively functioning in most multi-storey buildings. On the roof of the high-rise building there is an expansion tank for collecting excess water. The tank is not sealed, which allows vapors to escape into the external environment.

The open version is mounted without a circulation pump. The coolant flows naturally through the pipes. After heating in the boiler to a certain temperature, the pressure rises, and hot water, rising upward, pushes out cold water. The volume of water also increases when heated, so the excess goes to the expansion tank. The cooled coolant is again sent to the system.

Closed type of communication

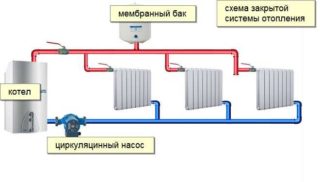

A closed heat supply scheme provides for a pump that provokes the movement of water through the pipes. Forced circulation is also realized using pipes, a boiler, radiators, an expansion tank. The metal tank is sealed, consists of two sealed parts, has the following filling:

- inner rubber diaphragm - heat-resistant membrane;

- small volume of gas - plant nitrogen or air accumulated in the pipeline.

The membrane divides the container into two compartments - for collecting excess heated water and for air location.

The coolant moves through the system, but at the moment it heats up, the reservoir valve picks up the excess. They enter the expansion tank, penetrate the membrane and are pushed back with the help of gas. After cooling, the circulation pump pumps water back into the system, while monitoring the pressure readings. Thus, the deaeration of the heat carrier occurs.

The main differences

The difference between open and closed heating systems is as follows:

- Expansion tank location. In the open - the top floor of a private house or the roof of a high-rise building. It is allowed to put it in a closed tank anywhere.

- Isolation from air access. Unlike an open line, a closed line is protected from the ingress of air currents. Additional pressure in the upper points eliminates airing of the batteries.

- The complexity of the arrangement. An open system will differ from a closed one in terms of the type of pipeline.Products of large diameter are mounted taking into account the location of the radiators, the slope of the air, the presence of a turn and rises.

- Organization costs. Closed heat and water supply requires financial costs for the purchase of thick-walled pipes. You can save money on an open system using small diameter lines.

- Noise level. Forced circulation in a closed line involves the use of a pump. When installed correctly, the equipment will be quiet.

Heating a closed-type house will save 10 to 40% of energy resources per year.

System connection options

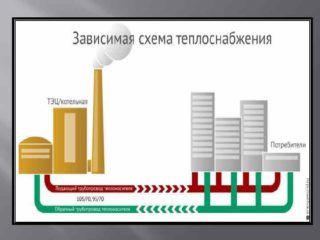

Dependent way

The specificity of the scheme is an in-house heating unit with an elevator. The heat supply station mixer mixes hot water from the external line with the return. At the same time, the coolant receives a temperature of up to 100 degrees. The benefits of dependent systems include:

- water supply for heating and supply directly from the heating main;

- simplicity and inexpensive price for input equipment for one subscriber;

- exposure to large temperature fluctuations;

- small pipe diameter;

- reduction of the heat carrier consumption.

Among the disadvantages of central heating are high water consumption, difficulties with temperature control and energy overruns.

The internal line is dependent on external heat supply.

Independent way

The system works on the principle of water heating in two isolated circuits. The mechanism of the external heating main works for a closed internal network without further mixing of the liquid. The advantages of an independent scheme include:

- the ability to connect any number of heat exchangers;

- use of water for heating and household purposes;

- no pressure fluctuations in the home circuit;

- temperature control in rooms with a thermostat;

- availability of drinking water in the hot water supply at home;

- filtration of the coolant from salts in a small circuit.

Disadvantages of communications - the need for periodic flushing of the heat exchanger, the cost of purchasing equipment and regulating elements.

Features of pipe routing

Depending on the location of the main pipe, the technology for connecting the batteries, the supply risers, the wiring technology is selected.

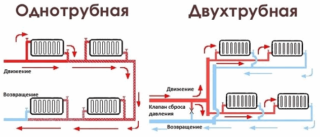

One-pipe method

For single-pipe wiring, a horizontal and vertical scheme is used. Laying pipes horizontally excludes the regulation of the amount of water, therefore bypasses are additionally used. The vertical arrangement of the highway is typical for high-rise buildings.

Two-pipe method

Two-pipe intake of wiring provides for the supply of two lines to one radiator - for supplying warm water and removing cold water. The following schemes can be implemented in an apartment or house:

- gravity - the circulation of warm water is carried out in a natural way;

- classical - a dead-end system;

- annular - the coolant moves along the way;

- radial - heat is supplied from the distributor to the radiators on an individual basis.

The two-pipe system is suitable for underfloor heating, where heating circuits are assigned the role of batteries, and pipes and a comb with a mixer are mains.

Types of communications by type of circulation

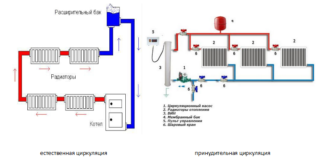

In open and closed pipelines, the coolant can move in two ways.

Natural circulation

The system is organized without a pump and operates on the difference in fluid density during heating and cooling.The coolant is heated in the boiler, becomes less dense and light, as a result of which it is directed upward. In the cold state, the water moves along the issuing riser - a pipe with a large diameter. Along the wiring and to the heating devices, the coolant moves from top to bottom, cooling when the heat is released.

In a cold state, the density of the water increases and it is directed to the heating tank. The pipeline is sloped. The system is distinguished by its non-volatility - it can be used in a private house or in the country. Among the disadvantages of natural circulation:

- the complexity of installation due to pipes with a large diameter;

- unaesthetic appearance;

- the need for periodic top-up of the coolant;

- small square of heated rooms.

The system uses a leaky open container.

Forced circulation

For communications, a circulation pump is used, which activates the movement of water. The system is characterized by simplicity of arrangement, advanced capabilities and small pipe diameters. The user adjusts the temperature himself or sets it in automatic mode. The lack of forced circulation is volatility.

Installation rules

The rules for connecting equipment and creating a system depend on its type.

Open system installation requirements

When arranging, you should:

- Select the lowest point for the heat source and the highest for the tank.

- Use pipes with a large diameter for the movement of the coolant.

- A narrow pipeline is required to normalize pressure.

- Install a high riser that distributes water evenly.

- Avoid a large number of turns, forks and junctions.

- Mount the system in a confined space - up to 159 squares.

- In private households, it is better to put a good circulation sediment.

The open system is suitable for a small country house or summer cottage.

Closed system installation procedure

If a closed-type heating system with a pump and an expansion tank is installed, it is necessary:

- Place the boiler in the basement and the expansion tank in the attic.

- Provide high-quality thermal insulation of rooms with a tank and a riser.

- Do not use a large number of fittings.

- Do not overheat the water.

- Drain the coolant if the system does not start in winter.

- Form a pipe slope of 2-3 mm per 1 m of the contour.

The principles for calculating the cross-section and slope of a closed heating pipeline are prescribed in SNiP 2.04.01-85.

Independent organization of the heating system

A good and high-quality heating option can be made with your own hands, taking into account the costs of design, the purchase of equipment and the complexity of the organization. The best option for a private house would be a closed type of communications with a circulation pump and tanks. Its creation is carried out as follows:

- Calculations of communications. Ordered from a design company or produced using an online calculator.

- Coordination of the project, obtaining permission and technical conditions.

- Purchase of equipment. You will need a heating boiler, a pump, pipes, an expansion tank, radiators (circuits, if a warm floor is planned), air vents, shut-off devices, automatic controllers.

- Boiler installation and boiler room equipment. A high-quality ventilation is organized in the room, a chimney is equipped. Walls, floor and ceiling surfaces are sheathed with fire-resistant materials.

- Installation of a circulation pump, distribution manifold and metering devices.

- Lining the pipeline to the points of location of the batteries.

- Installation of radiators.

- System pressure testing. The first launch is carried out in the presence of specialists.

The collector circuit is difficult to install and is expensive, but due to the adjustment of the contours, the living conditions in the room will be comfortable.

There are several differences between open and closed heat supply lines. It is worth choosing a heating system depending on the conditions and place of installation.An open highway is easy to organize yourself. Specialists should create a closed system.

Features of open and closed systems, in the first two pictures there is no difference, the expansion tank is located at the very top and all the air flows into it, but how to add water to the sealed tank? it doesn't open. There is a tap on the main heating pipe after the boiler, why? turn off the heating in this way or what? and on each battery for what? every day to run around the rooms and turn these taps, in general, there is an automatic system for this.

Further it is written the main differences

The difference between open and closed heating systems is as follows:

Expansion tank location. In the open - the top floor of a private house or the roof of a high-rise building. It is allowed to put it in a closed tank anywhere.

Further

Closed system installation procedure

Place the boiler in the basement and the expansion tank in the attic

Yeah, the boiler is in the basement, the gas workers will come and go nuts. And if an expansion tank is built into the wall-hung boilers? it is necessary to remove it from there, well, advice. Further

Independent organization of the heating system and right there a photo of boilers, and next to it is an expansion tank, is it that the basement and the attic are the same room? In general, there are many contradictions in this article.

In multi-storey buildings, in the city, there is no open heating system, only a closed type and under pressure.

from the very beginning, you need to understand that not a heated coolant (water, antifreeze, oil) tends to rise in the upward, but just cooled down and as a result denser and heavier (coolant) flowing down to the bottom along a properly mounted heating system displaces the heated one (less dense, more light) coolant. Having understood this, any reasonable person will understand the principle of the natural circulation system. And where the expansion tank is located does not matter at all. Best regards, WELDER from the private sector.

The author confuses the concepts. An open heat supply system is when water for hot water supply is taken directly from the heating network and mixed with a cold one to the required temperature. An example is the heating of Yekaterinburg from SUGRES. Closed system when domestic hot water is heated by network water in heat exchangers. Heating Kurgan example.

Namely, water is taken from the open water for hot water supply, and often, in connection with this, water treatment is not carried out, respectively, the service life of the pipelines is reduced. In our case, for example, the twentieth diameter clogs in 5-6 years of service.