Combined heating boiler is a new equipment that uses both gas and electricity for space heating. This technology will provide the house with heat in the event of a lack of electricity or a gas supply failure. To use the electric gas boiler as efficiently as possible, you need to install a combined heating system in the house. It is designed at the beginning of the construction of the structure. Water is used as a coolant in such a construction. Correct installation and adjustment will increase the service life of the boiler.

Characteristics

Gas-electric heating devices regulate the operating mode (on, off) automatically. Thus, the required temperature is maintained in the room, and resources are spent as economically as possible.

Combined heaters have the following characteristics:

- Small size. The design of such units provides for oversized combustion chambers for gas combustion and heat exchangers with built-in heating elements.

- Low consumption of electrical energy. The boiler mainly operates on gas, and the electric heater is started up if necessary for operational heating of water, as well as in the absence of a gas mixture supply.

- Reasonable price. It is formed due to the absence of a separate chamber (combustion chamber), since the heater is built into the heat exchanger. In equipment where there is no secondary circuit, an option is planned for the possible connection of a water heater.

- Heating elements with low power. Most of the models on sale only support the specified temperature value. Water heating heating elements start to work in case of starting the electric mode of operation.

Gas is considered an economical fuel, which cannot be said about electricity. In this regard, for heating houses in an area with an underdeveloped gas supply, it is better to find a boiler option that runs on a different type of fuel.

An electric gas boiler costs on average 70-80% higher than a purely gas boiler. But since the installation of such a unit is cost-effective, its cost is fully paid off within 3-4 years.

Advantages and disadvantages

Electric gas heating boilers, like other devices, have their pros and cons.

Important advantages of units for 2 types of fuel are:

- high efficiency (reaches 97%);

- compact size;

- uncomplicated maintenance and repair of equipment;

- significant savings in funds required to pay for resources;

- easy control;

- no waste from fuel combustion.

The gas-electric boiler also has disadvantages:

- high price in comparison with devices for 1 type of fuel;

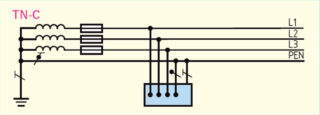

- a three-phase network is required.

After a few years, the cost of an economical boiler pays off, since funds are taken care of to pay for the use of resources. The versatility of the unit greatly facilitates everyday problems.

The gas electric boiler has an important distinctive feature: the presence of several outputs, allowing the device to be used as a multi-circuit one. Such a boiler heats radiators, heats the sauna room, heats the pool and water for household needs.The "warm floor" design can also be heated by such a unit. Summer residents use one outlet to heat greenhouses.

Types of boilers by the number of circuits

Single-circuit devices are heating units designed only for heating network water. Double-circuit devices also additionally provide hot water supply. They are a good option for installation in country houses. At the same time, two important tasks are being solved: high-quality operation of the heating system and the constant availability of hot water are guaranteed.

Single-circuit

The power of such devices is quite enough for space heating. But such a unit cannot provide hot water on a regular basis. For these purposes, an additional DHW cylinder must be connected.

Double-circuit

If staying without hot water is impossible, you need to immediately purchase a double-circuit gas-electric boiler. Unlike a single-circuit one, its design contains an additional heat exchanger, which solves the problem of heating water. If the power allows, you can increase the number of taps. To minimize the loss of water temperature, they should be located close to each other (boiler and parsing points).

All the disadvantages of gas-electric units are determined by the technical characteristics and depend on the manufacturer. When choosing a heater, it is recommended to contact a specialist.

The nuances of choosing an electric gas boiler

The design provides for 2 chambers: for gas combustion and for electric heating elements. The change of modes occurs automatically. In individual boilers, it is possible to set a cyclical operating mode. This is useful in cold temperatures that can last for a long time. When a sufficient temperature indicator is reached, the unit switches from gas to electricity. The combined use of both types of fuel allows you to save expensive resources, to make heating independent.

If the electric gas boiler does not have a tank for heating water, a boiler is required. An electric pump is used to improve the water circulation. The latter does not provide the ability to operate the gas part of the unit in the absence of electricity. This detail limits the use of such a device in multi-storey buildings.

Installation and operation rules

The combined heating system is installed by specialists from the gas service or a special organization according to a pre-approved plan.

Stages of work:

- Installation of supports that will provide the required level for the heating unit. As a rule, they are present in the kit of the latter.

- Connecting the boiler to the gas supply.

- Electrical connection.

- Installation of special filters for water and gas.

- Tightness testing and cleaning of the heating system.

- Connecting the boiler to the pipeline.

- Establishing the work of the chimney.

- Test run of the heating system, troubleshooting.

- Final adjustment of the heating system.

Installation of a gas-electric boiler is allowed in a room where, according to the rules and regulations, supply and exhaust ventilation is equipped.

Basic rules of operation:

- During the operation of the combined unit, an acceptable thrust is required. In this regard, the chimney must have a sufficient cross section.

- The used chimney must be insulated in order to avoid ignition of the parts that come into contact with it.

- During regular operation of the boiler, the ash pan should be periodically cleaned. The frequency of such procedures depends on the degree of gas combustion and the intensity of the unit operation.

- There should be a sheet of steel in front of the combustion chamber to protect the floor from sparks.

Electric gas heating boilers are considered the most technologically advanced and sophisticated.

Popular manufacturers

On the Russian market, combined heating devices are represented by products of domestic and foreign manufacturers. The most popular are:

- Navien (Korea). Gas-electric boilers of the Korean manufacturer are fully adapted to the conditions of Russia. They are not damaged by frequent power surges, do not respond to a drop in gas pressure. The use of such devices provides an opportunity to save money due to the low gas consumption. High-quality protection guarantees complete safety during operation. Operating modes of heating units are determined by self-setting. They can be controlled using the remote control.

- Hercules (Russia). The gas-electricity boiler can heat a room up to 300 m2. In a wide model range of Hercules, there are devices with different configurations depending on the functions. The presence of two circuits provides space heating, constant hot water supply without additional burners. In such devices, the DHW circuit has a protective cover, which extends the service life of the unit.

- CTC (Sweden). The manufacturer produces heating units with a power of 45 kW and a heating capacity of up to 500 m². Their distinctive feature is the equipment of heating elements, the power of which is 15.75 kW. Internal automation allows you to maintain a constant water temperature. Programming devices can be included in the design of boilers, which allows you to adjust the operation in accordance with outdoor temperature conditions.

When choosing, first of all, it is recommended to be based on the area of the room, its insulating properties, the availability of the required amount of money.

An electric gas boiler for heating a private house has a complex design. With its help, it is possible to economically and efficiently heat a country house in an autonomous mode. It is expensive, but the purchase and installation costs pay off quickly.