Correctly selected material for the manufacture of pipes for organizing heating is the basis of the efficiency of the entire system. Until recently, there was no particular alternative - steel lines had to be installed. However, with the development of the polymer industry, it has become important to make heating with metal-plastic pipes of a private house with your own hands.

Features of metal-plastic for heating

The main performance characteristics for heating pipes are a long service life with periodic temperature fluctuations, as well as minimal heat losses. Heating on metal-plastic pipes fully meets these parameters. A distinctive feature of these designs is the use of several materials of different nature and properties to achieve the desired result.

The main material of manufacture is often high-density cross-linked polyethylene. But besides it, simple polyethylene or propylene can be used. To prevent oxygen molecules from entering the coolant, the pipe has a foil layer. They are bonded to the outer and inner polymeric shell with an adhesive layer. This is a prerequisite, since you cannot make effective heating from metal-plastic with your own hands from highways without a waterproof shell. Otherwise, the oversaturation of water with oxygen will lead to an increased rate of corrosion of the metal elements of the system.

For the consumer, it is not the technical, but the operational properties of the heating pipes that are important. Therefore, we will not consider the manufacturing technology in detail, but focus on the special aspects of metal-plastic:

- Which is better to take - cross-linked polyethylene for heating or metal-plastic? The latter has a different degree of thermal expansion of its elements - polymer shells and a foil layer. Therefore, on long sections of the pipeline, it is necessary to install expansion loops;

- The operating temperature is limited to 95 ° C. Exceeding this value will lead to deformation of the structure;

- To connect the elements of the line, you can use several types of fittings - glued, threaded or clamped. If it is necessary to make reliable heating of a private house with metal-plastic, it is recommended to use the latter type of connectors.

What else is the difference when choosing - metal-plastic or polypropylene for heating? Ease of installation first. A special welding machine is required to connect polypropylene pipes. Reinforced-plastic pipes are mounted using a pipe "gas" wrench. But the requirements for the professionalism of their installation are much higher. Its reliability will depend on the degree of effort applied, correct cutting and drawing up a heating scheme.

The reinforced plastic pipe can be bent up to a radius of 12 mm. This applies to models with a diameter of 20 mm or less. With an increase in the section, the minimum bend radius increases. This must be taken into account during installation.

Selection of pipes and accessories for the heating system

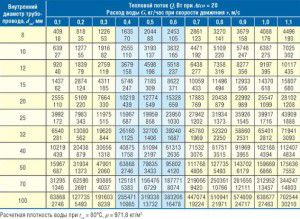

To organize heating from metal-plastic with your own hands, you need to choose the right pipes and accessories.First of all, the optimal diameter is determined - the throughput of the system will depend on it.

Metal-plastic pipes

What is more convenient for heating installation - metal-plastic or polypropylene? Metal-plastic pipes are supplied in coils, the length of which ranges from 50 to 200 m. Polypropylene products are made up to 6 m long. Also, when choosing a material for the manufacture of heating from metal-plastic pipes, you need to take into account their quality, namely:

- The minimum thickness of the foil cladding shall be 0.3 mm;

- The connection of the aluminum layer must be performed using seamless technology;

- No delamination should be observed on the pipe cut.

It is imperative to make sure that there are no bends in the bay. This can affect the integrity of the aluminum shell.

Pipes from Rehau, Oventrop and Henko are distinguished by a high degree of reliability. In the assortment of their products, you can pick up fittings and other additional components for the line.

Fittings for reinforced plastic pipes

It is best to use press fittings for the connection. They have the same design regardless of what was chosen - cross-linked polyethylene for heating or similar metal-plastic.

The best perfor- mance is provided by the models with a double sealing contour. They are made of stainless steel and copper alloy (brass). The latter are characterized by a more affordable cost, but have a shorter maintenance-free service life.

An important factor in the organization of heating a private house with metal-plastic is the cost of components. This parameter directly depends on the manufacturer, as well as the technical characteristics of the elements.

| Name | price, rub. |

| Pipe 16 mm | 16,7 |

| Pipe 20 mm | 22,61 |

| Pipe 26 mm | 42,77 |

| Coupling, 20mm | 91 |

| Connecting tee, 20 mm | 67,3 |

| Crosspiece, 20 mm | 129,8 |

If the main parameter for choosing metal-plastic or polypropylene for a heating system is the cost of components, then the former will "lose". This is associated with high labor costs during production.

The marking must indicate that the product can be used in heating systems. Not all reinforced plastic pipes are designed for high temperatures.

Installation of heating from metal-plastic pipes

To install heating made of metal-plastic, you yourself need to purchase special pruning shears and a calibrator. It is designed to flatten the end of the pipe before being inserted into the clamping fitting. It is not difficult to make it with your own hands, but at the same time there is a high probability of making a mistake in size - the permissible deviation is 0.5 mm.

After purchasing, the pipes must lie in a room with a normal temperature (from 15 to 25 ° C) for at least 1 day. If you need to bend the line in a certain area, a special spring is purchased.

Having cut the pipe to the desired size, you should clean its end. The fitting is then mounted and clamped with a pipe wrench. The force should be relatively small so as not to damage the body of the fitting. For fixing to a wall or floor, you need to use special clips.

Another difference between cross-linked polyethylene for heating and metal-plastic is the mandatory check of the connecting nodes before starting the heating system. With pressure surges, they can lose their tightness or even collapse.

In the video, you can get acquainted with the recommendations for the installation of reinforced-plastic pipes: