During the operation of the heating system, the coolant may freeze. This leads to the creation of emergency situations. They can be avoided only by replacing the water in the highways with a special composition, the freezing point of which is much lower than 0 ° C. Is it possible to make a similar non-freezing liquid for home heating systems with your own hands?

We make antifreeze ourselves

It should be noted right away that ordinary water is the best type of heat carrier. It has sufficient heat capacity, optimal density, and affordable cost. Therefore, if the likelihood of exposure to negative temperatures on the heat supply is minimal, it is best to use distilled water.

But if it is impossible to comply with this condition, a special non-freezing liquid for heating boilers will be required. It is a solution in which water occupies up to 70% of the total volume. The rest is additives that reduce the crystallization threshold to -60 ° C. They include:

- Main component - ethylene glycol, propylene glycol or glycerin. This antifreeze liquid for a home heating system has a high viscosity index, which leads to the desired effect;

- Additives... It is thanks to them that the non-freezing liquid for water heating does not foam, and does not form a crystalline precipitate when the temperature rises.

The problem of self-manufacturing of such a composition is the correct selection of the last component. All manufacturers do not disclose the full list of components. But even knowing how to make the correct composition, it is impossible to do this at home - this will require special equipment and adherence to manufacturing technology.

How to make an antifreeze liquid for heating yourself, and what are the consequences of its use?

- An increase in the level of foam during heating of the coolant will entail a rapid formation of sediment on the walls of pipes and radiators;

- Reducing the heat transfer of a homemade anti-freeze liquid. This will cause a significant decrease in heating efficiency;

- A self-made non-freezing liquid for heating with your own hands can negatively affect the steel elements of the system due to the high oxygen content. Corrosion processes will accelerate.

Any non-freezing liquid for stove heating or solid fuel boiler should not cause these undesirable effects. Therefore, to maintain the safety of the system, it is recommended to use only high-quality antifreeze liquid for hot water heating from a reliable manufacturer.

Before using antifreeze, you should familiarize yourself not only with its composition and recommendations for use, but also carefully study the instructions for the heating boiler. It should indicate the types of coolant that can be poured.

Types of antifreeze liquid for heating

Having decided that non-freezing coolants for the heating system should only be of factory quality, you can start choosing a certain composition.It must be adapted to a certain heat supply scheme, and its performance cannot degrade the parameters of the system.

Before pouring an anti-freezing liquid into the heating system, you need to find out if it will negatively affect the heat supply components. To do this, you should read the instructions for use, which must be attached. It is also important to pay attention to the main component of non-freezing liquid for heating boilers. Not only the state of the heat supply components depends on this, but also the operating conditions:

- Ethylene glycol... It is highly toxic. Therefore, it can only be used in closed circuits. Difficulties may arise when pouring this type of freezing liquid into the heating system. In a vaporous state, it is dangerous to human health;

- Propylene glycol... In fact, it is a food additive, therefore it can be used in both open and closed heating systems. Unlike ethylene glycol, the crystallization temperature is at the level of + 80 ° C, which makes it possible to use it for the operation of solid fuel high-temperature boilers. The only drawback is the high cost;

- Glycerol... The most popular type of non-freezing liquid for stove heating. Its performance is slightly lower than that of propylene glycol. However, along with this, the cost of glycerin antifreezes is an order of magnitude less. The disadvantages include high fluidity. This can affect the tightness of the pipelines. The way out is to replace rubber gaskets with paronite ones.

Currently, the use of an antifreeze liquid for a home heating system based on glycerin is the best option.

| Name | Structure | Price, rub / l |

| Warm house -30 ° С | Propylene glycol | 65 |

| Dixis -65 | Glycerol | 75 |

| Comfort technology -65 | Ethylene glycol | 120 |

Manufacturers offer 2 types of non-freezing coolants for the heating system - ready-to-use and concentrate. For large heat supply schemes, it is more profitable to purchase concentrate. However, this complicates the process of filling the system.

When purchasing a ready-to-use liquid, you need to pay attention to the lower critical level of the freezing point. It can be from -25 ° C to -65 ° C.

Features of pouring antifreeze into the heating system

In order not to make an anti-freezing liquid for heating yourself and at the same time risk the performance of the entire system, it is necessary to purchase a ready-made composition. However, in addition to this, you should familiarize yourself with the filling technology.

If there is an old coolant in the system, it should be drained. In this case, it is recommended to check its condition. The degree of contamination will indicate the relevance of complex cleaning. It is performed before pouring antifreeze into the heating system. The subsequent stages of work consist in the implementation of the following points:

- If antifreeze was used before - a complete flushing of the system is mandatory. Otherwise, mixing of two different antifreeze fluids for furnace heating may lead to undesirable chemical reactions;

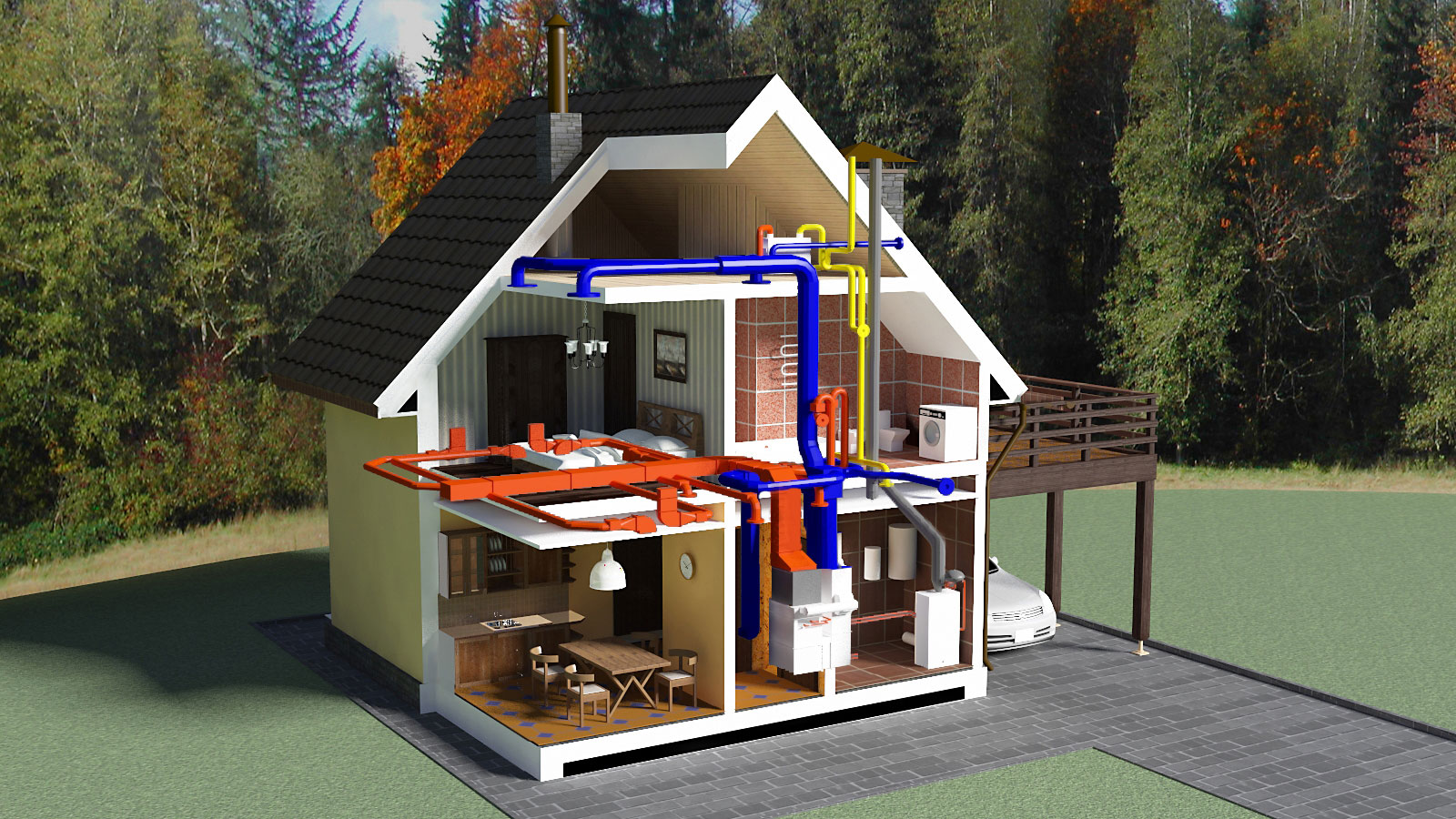

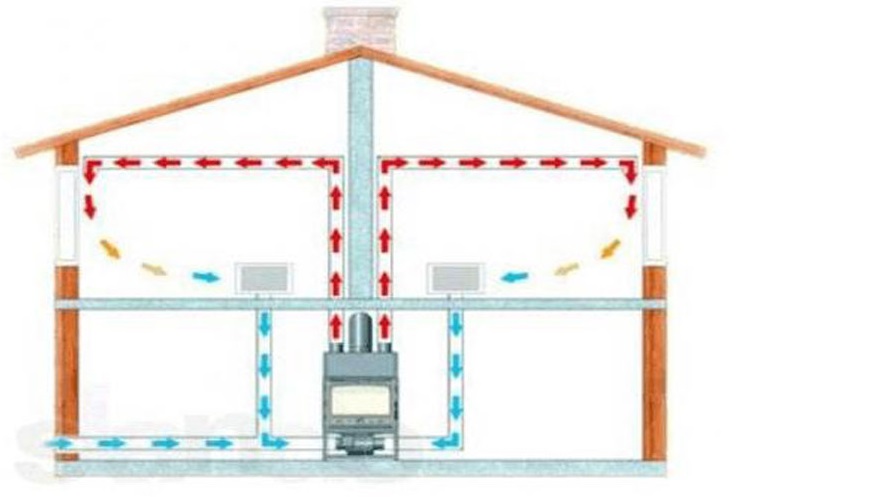

- Closed system... In it, the filling point should be lower than all other heating devices. With the help of pumping equipment, the heating system of a private house is filled with non-freezing liquid. It is important that the pressure in the pipes does not exceed 3 atm;

- Open system... For her, the use of antifreeze liquid for hot water heating is not recommended. Continuous contact with air can lead to a significant increase in foaming. Filling is done through the upper expansion tank;

- Heating testing... The temperature in the system rises gradually. At the same time, the tightness of all units is checked, as well as the absence of extraneous noise during the circulation of the coolant.

During operation, you will need to top up antifreeze liquid for heating yourself. Therefore, it is recommended to purchase it with a margin - 15-20% more from the calculated volume of the system.

You cannot make an anti-freeze liquid for heating yourself. Also, the use of automotive antifreezes is not recommended, since in most cases they are made on the basis of unsafe propylene glycol.

Restrictions on the use of antifreeze in heat supply

Despite all its positive aspects, not every non-freezing liquid is suitable for heating boilers. Improper use can lead to gradual destruction of the heat exchanger and rapid failure of expensive equipment.

In addition, there are a number of other restrictions that must be taken into account when using an anti-freeze coolant for heating systems:

- Many models of double-circuit boilers are not designed for antifreeze. It can get into the DHW system, which is an undesirable factor;

- Non-freezing liquid has a negative effect on the galvanized surface. There is a rapid destruction of the protective layer and, as a result, the failure of the heating element;

- Since the viscosity of antifreeze is much higher than that of water, it is necessary to complete the heating with powerful circulation pumps. The lower the critical level of the freezing temperature, the greater the capacity of the pumps;

- Replacement of antifreeze should be carried out strictly according to the manufacturer's recommendation. It loses its properties over time, which directly affects the performance of the heating system.

Antifreeze concentrate can only be diluted with distilled water. An ordinary flow-through is unsuitable for this - a large number of third-party elements can cause an undesirable chemical reaction.

The video describes in detail the parameters for choosing antifreeze for heat supply systems:

advise what to pour (what non-freezing) into the pipe, into the garage? The length of the system is 36m.