The issue of recycling used oil has arisen relatively recently. First of all, this is due to a decrease in the cost of purchasing an energy carrier. Therefore, heating the house and garage with do-it-yourself boilers for mining will be optimal if there is an opportunity to purchase a large amount of this fuel.

Features of heating during mining

In the nomenclature of heating equipment manufacturers, there are practically no boilers for heating during mining. In principle, this type of energy carrier can be used by any models that run on liquid fuel. The only difference is in the size of the nozzles and the air flow rate.

What is the heating of a private house for working off with your own hands? First of all, you need to understand that not every oil can be used as a fuel. The ethylene glycol alcohol content must not exceed the maximum level. Otherwise, the intensity of combustion will sharply increase and, as a result, overheating of the boiler chamber. Therefore, it is recommended to take a small amount before purchasing a batch and try it on a specific boiler model.

Even heating a garage for working off with your own hands has a certain specificity. During its arrangement, the following factors should be taken into account:

- Economic... At present, the cost of used oil is approaching the price of diesel fuel and amounts to 22-25 rubles / kg;

- Pollution degree... This indicator directly affects the frequency of burner maintenance - the more debris in the oil, the more often the nozzle will need to be cleaned;

- Organization of fuel storage... The oil contains essential elements, so it must be kept in an airtight container. To do this, you can use barrels (which is not very convenient) or an analogue of gas holders (high cost).

In addition, properly organized heating of the garage by working off should provide for the removal of carbon monoxide gases. To do this, you need to make a chimney, the minimum height of which should be 4 m. Otherwise, condensate will accumulate on the inner surface of the pipe and the draft will decrease.

Before purchasing used oil, you need to find out its main indicators. Freezing - not lower than -19 ° С; flash point - around + 55 ° С; sulfur content - no more than 1.2; density about 0.82.

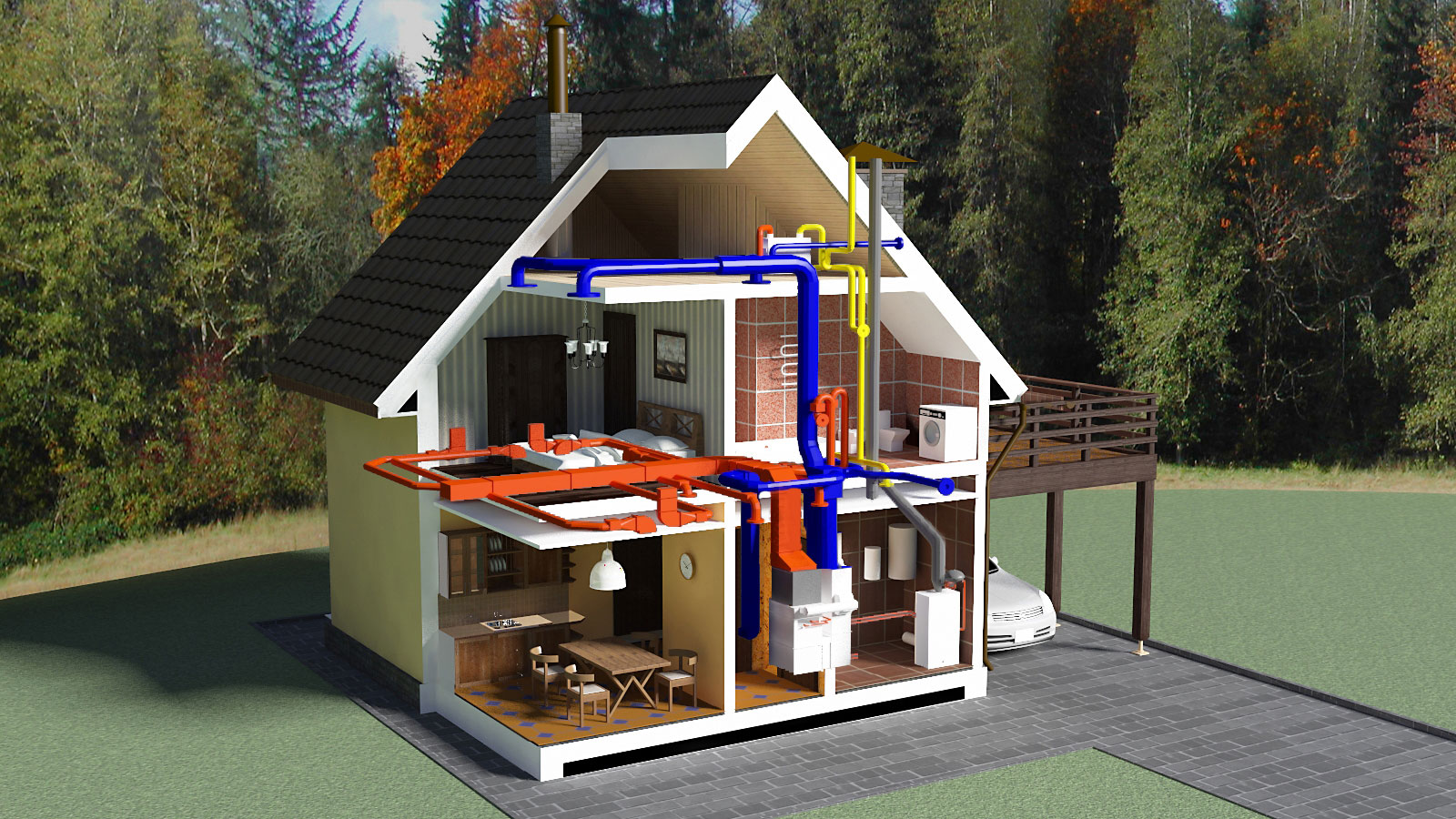

Heating system complete set

The best option is to purchase a ready-made boiler. However, the average cost of a 30 kW model is currently over 160 thousand rubles. Therefore, oil recovery heating is often done with the help of a burner and the body of an old solid fuel boiler.

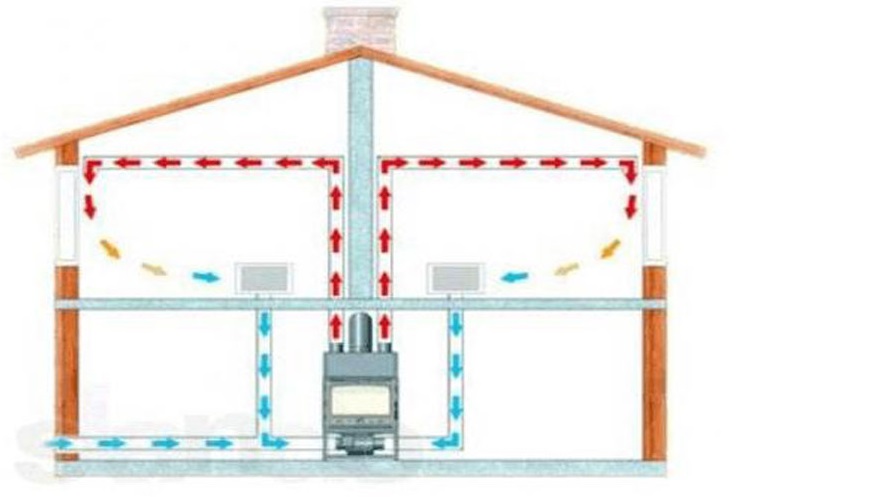

Heating circuit for mining

First, the place where all the heating equipment will be installed is determined. The piping layout and standards for air exchange in the boiler room or garage must be taken into account. It should be at least 180 m³ / hour for an area of 25-30 m².

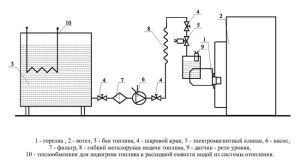

For normal operation, you will need a container and a pipeline to supply fuel to the burner. Its power is determined by the area of the room (house, garage), as well as the heat loss of the building. Correctly organized heating for working off with your own hands should contain the following components:

- Fuel storage tank... It should provide for a mechanism for filling and removing the formed vapors;

- Burner supply line, including: pump, shut-off valves, solenoid valve. The latter is necessary to regulate the rate of fuel supply;

- Chimney... During combustion, working off in the heating system produces a large amount of carbon monoxide gases. The minimum pipe diameter for their output is from 100 mm and more.

During operation, combustion products accumulate on the surface of the injectors. A special kit is purchased to clean them. In this way the service life of the main components of the burner can be increased.

An ordinary oil filter can be used as a filter. First, you need to calculate its optimal throughput, based on the characteristics of the burner.

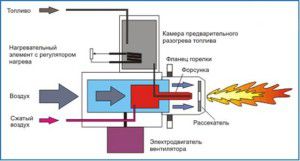

Boiler or burner for heating at mining

When choosing a burner, you need to build on its performance. Like any boiler for heating during mining, it is characterized by power, overall dimensions and additional control components.

Compressed air must be provided for most models. It is necessary for the formation of a combustible mixture. You can actually do this for heating a private house for working off with your own hands using a compressor. An alternative is to purchase a burner model with an already built-in air blower - a turbine. Despite the relatively high cost, this way you can optimize the place for installing the equipment necessary for heating the garage for working off with your own hands.

You also need to take into account the main characteristics of the burner:

- Oil consumption. On average, 0.09 kg of oil will be required per 1 kW of thermal power;

- Electricity consumption - from 0.5 to 1 kW;

- Maintainability. Possibility of replacing components and assemblies after their breakdown.

An important issue when heating a garage is the cost of the burner. The price of models from well-known brands can reach several hundred thousand rubles. But, despite this, the high cost in most cases is a guarantee of quality.

| Model | power, kWt | Cost, rub. |

| SMART BURNER, В-03 (China) | 35 | 96000 |

| KROLL, KG / UB В20 (Germany) | 38 | 142200 |

| EnergyLogic, B-40 (USA) | 40 | 260000 |

| AR-CO ВR-10, (Italy) | 93 | 232000 |

On the Russian market, there are many "handicraft" industries that offer components for heating oil extraction at more than affordable prices. But the quality of their products is poor. The exception is the company "Heat". They manufacture prefabricated waste oil boilers. The average cost of a 20 kW model is 130-150 thousand rubles.

For each type of burner, manufacturers will determine the maximum possible oil contamination rate. It can be adjusted by installing a nozzle with a large nozzle diameter. But then oil consumption will increase.

Do-it-yourself boiler for working off

Analyzing the pricing policy of manufacturers, many owners have a desire to make heating for working off with their own hands. On the network you can find options for making burners from scrap materials, including accessories from cornices.

But is it possible to use testing in a heating system using such structures? It is necessary to take into account not only their extremely low efficiency, but also the almost complete lack of work safety. When organizing heating of a private house for mining, they are independently guided by standards and safety requirements. The slightest violation in the assembly technology or non-compliance of the material with the performance indicators will lead to emergency situations.

Why is it not worth making a boiler or burner for heating the garage room for testing with your own hands?

- It is impossible to regulate the functioning of the burner without special devices - the fuel consumption will be too high (will lead to attenuation) or insufficient;

- To create an air-fuel mixture, adjust the operation of the compressor or fan;

- Lack of emergency shutdown facilities.

So how to make heating a garage with waste oil with minimal financial investment? The only option is to purchase a used, but factory-made burner. You should also not forget about the organization of the fuel storage site. For this, empty drums with a sealed lid can be used.

An example of how to make heating a house or garage with boilers for working off with your own hands and see the burner test can be in the video: