The organization of heating using a solid fuel boiler requires maxims of attention and knowledge of the nuances of drawing up a diagram and installing equipment. It is important to use such a system in the absence of the possibility of connecting a gas main or in the presence of relatively cheap solid fuel. Consider the options for how you can make solid fuel heating of a private house with a boiler and a stove, schemes and selection parameters.

Rules for the organization of solid fuel heating

The main difference that a heating system with a closed-type solid fuel boiler has is the type of fuel used. Coal, firewood, peat or fuel briquettes are used as an energy carrier. All of them are characterized by high energy consumption and, as a result, intense heat release.

In order to make heating with a solid fuel boiler with your own hands, you will need to familiarize yourself with the rules for its organization. They directly depend on the chosen scheme, the piping system and the coolant used.

A characteristic feature is the correct installation of heating with a solid fuel boiler. The source of thermal energy and fuel must be located in different rooms, and in addition to the installation rules, safety measures for the operation of heating are observed.

The basic rules for the design and practical implementation of the heating system scheme for solid fuel boilers and furnaces are as follows:

- Use of non-flammable materials... When installing a stove or boiler, the floor, walls and ceiling in the area of the chimney must be fireproof. Those. when exposed to high temperatures, these materials should not spontaneously ignite or smolder;

- Stabilization of work... The main danger in the operation of a solid fuel boiler for hot water heating is overheating of the water in the heat exchanger. To prevent this, the boiler or stove provides for the possibility of regulating the supply of air necessary to maintain the burning process of wood. This can be a system of valves connected to a mechanical temperature controller;

- Supply and exhaust ventilation... The classical scheme for installing heating from a solid fuel boiler provides for air exchange in the room where the equipment is installed. During its operation, combustion products will inevitably enter the room. Supply and exhaust ventilation will remove them, thereby preventing a dangerous concentration of CO2 for humans.

Factory or home-made solid fuel heating boilers should be installed in separate boiler rooms. Exceptions are models with low power, which are equipped with a hob. But in this case, all safety measures must be provided in the kitchen.

The basic rules for the arrangement of boiler rooms, in which double-circuit solid fuel heating boilers will be installed, are described in SNiP II-35-76. Read this document before installing the equipment.

Schemes of water solid fuel heating with a boiler

The choice of a heating scheme is the first stage in the design of a home's heat supply. When using solid fuel equipment, special attention is paid to the installation and connection diagram of a solid fuel boiler to the heating system.Installation instructions directly depend on the type of heat supply, piping.

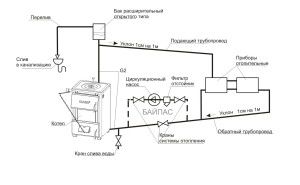

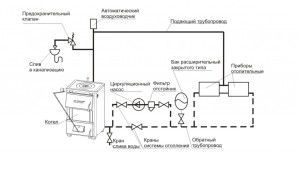

The most common heating scheme is an open system. This is due to the fact that a solid fuel boiler for heating a private house can overheat. In a closed system, pressure stabilization is provided by a diaphragm expansion vessel and a safety group. But if the temperature and thermal expansion reach a critical point, pipes may burst.

For an open system, it is recommended to use two-pipe wiring. In such a scheme for connecting a solid fuel boiler to the heating system, the following heat supply parameters will be provided:

- Uniform distribution of heat energy... The coolant flow will be artificially divided for each radiator;

- Operational safety... This is important when installing a homemade solid fuel heating boiler;

- Possibility of expanding the heating area... It depends on the power of the equipment. In the installation scheme for heating from a solid fuel boiler, a power reserve should be provided for connecting additional radiators and batteries;

The disadvantage of this scheme of heating systems for solid fuel boilers is the large diameter of the pipes - from 32 to 40 mm. This entails an increase in the volume of the coolant and, as a consequence, a large fuel consumption to maintain the required temperature level. Therefore, when installing heating with a solid fuel boiler, preference is given to a closed circuit.

The difference lies in the creation of an increased pressure inside the system from 1.5 to 4 atm. Modern heating systems with a closed-type solid fuel boiler more stably support the operation of the heat supply, require less fuel. To install the supply lines, pipes with a diameter of 16 to 24 mm are used. This entails a decrease in the volume of the coolant, compared with an open system.

Professional installation of a double-circuit solid fuel heating boiler in a closed system is possible only with the following components:

- Diaphragm expansion tank... It is necessary to compensate for small pressure surges in the system. Mounted on the return pipe;

- Security group - air vent, drain valve. The primary block in heating with a solid fuel boiler with its own hands is mounted on the supply pipe immediately after the boiler. It is also mandatory to install an air vent at the highest point of the system;

- Circulation pump... With its help, the speed of movement of the coolant increases, the heat distribution is stabilized.

In a heat supply system with a closed-type solid fuel boiler, pressure and temperature sensors are mounted to monitor the operation. The same set of instruments must be in the boiler. If they are not included in the package, you should purchase and install them.

The least common is collector heat supply with a solid fuel boiler with your own hands. This is due to the high consumption of materials. Such schemes for installing heating from a solid fuel boiler are relevant for houses with an area of 200 m2 or more.

Air heating with a solid fuel boiler

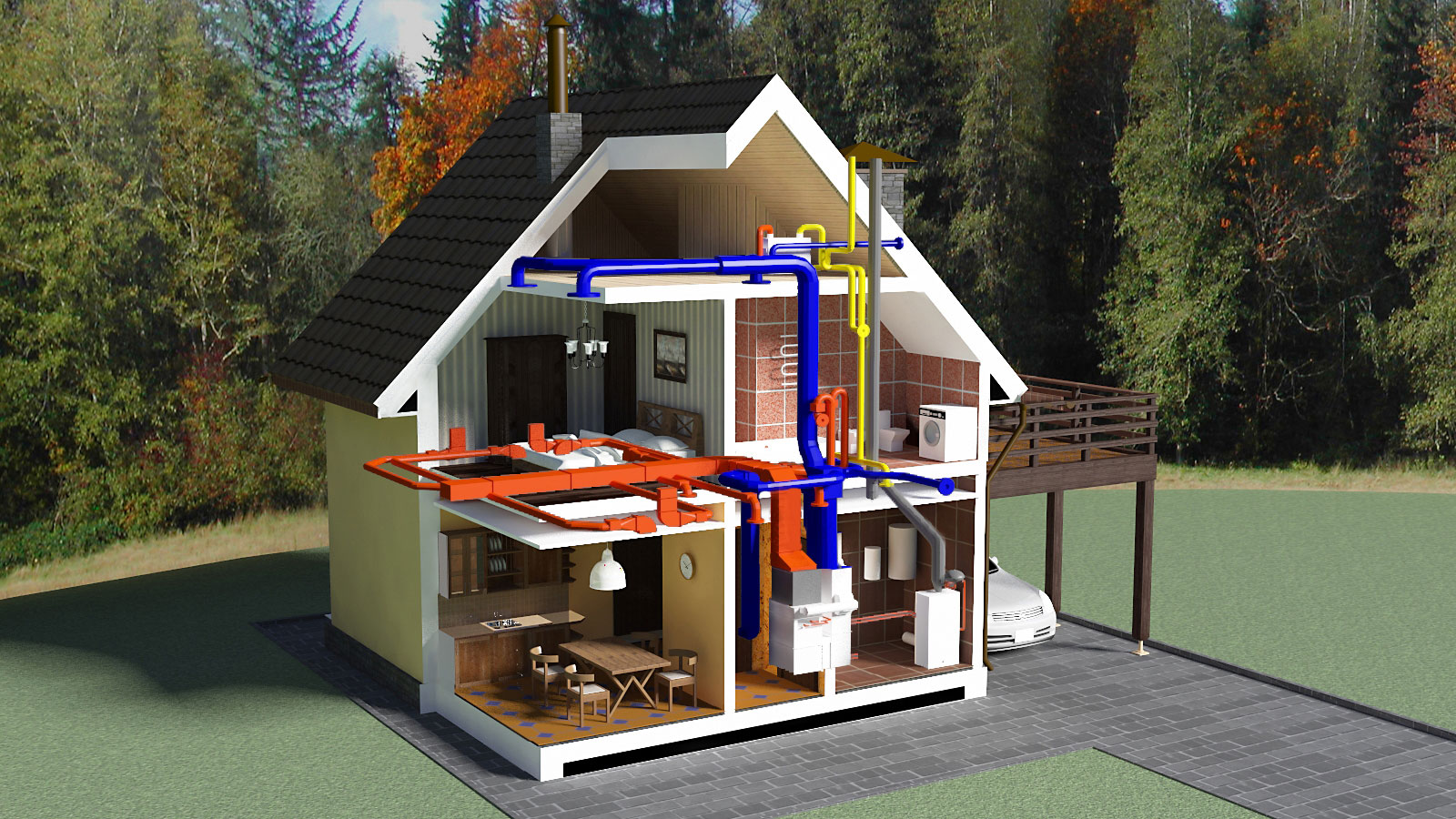

Solid fuel boilers for air heating are an alternative to water heating. They differ not only in the type of coolant, but also in design. To form the circulation of warm air flows in solid fuel boilers for air heating, a pipe system is installed.

They are intended for heating small spaces. Since the air is heated due to the system of channels in the boiler structure, it is impossible to maintain the temperature in other rooms of the house in this way. The advantage of such a heat supply is that it is unnecessary to draw up a diagram for a heating system with a solid fuel boiler.It is important to choose the right location of the structure in the room so that the air is evenly heated.

Features of the operation and operation of solid fuel boilers for air heating are as follows:

- Minimum primary expenses for the organization of heating... Unlike the complete set of solid fuel boilers for water heating with pipes and radiators, it is enough to purchase only a stove to install air heating;

- Design mobility... Judging by the reviews, solid fuel heating boilers can be quickly installed in another room. It is important that there is a chimney for connection to the boiler;

- Possibility of self-production... It is only important to choose the right design scheme and material. But many homemade solid fuel boilers for heating have worse characteristics than factory models.

Another disadvantage of this type of equipment is the lack of double-circuit solid fuel boilers for heat supply in the model range. There are options for installing an indirect heating tank on the chimney, by analogy with sauna stoves. But the volume of the tank will not be large enough to provide DHW.

Despite the ease of installation of solid fuel heating with an air-type boiler, you should still ensure all safety measures for its operation - air circulation in the room, fire safety.

Water heating schemes with a solid fuel stove

The stove is a traditional source of heat in a private home. However, for buildings with a large area, the installation of classic models will be impractical. This is due to the relatively low efficiency and limited heat distribution. Therefore, a solid fuel stove with a water heating boiler is increasingly being installed.

Structurally, factory models are similar to boilers, but have a number of features. First of all - small size. Since the main task of a solid fuel stove with a water heating boiler is to provide heat supply in a relatively small area - the maximum power of such structures is usually 9-10 kW. This disadvantage is compensated by the affordable cost and ease of installation. Unlike solid fuel boilers for water heating, a stove can have an additional function - a hob. Therefore, they are installed in the kitchen.

Most often, steel furnaces with a water heating circuit are purchased for heating a summer cottage or a small country house. Due to their unique properties, these heating devices have a number of advantages:

- Small size... They allow you to place the structure in a limited area of \ u200b \ u200bthe kitchen in the house;

- Choosing the type of solid fuel... To operate a solid fuel stove with a water heating boiler, you can use coal, firewood, peat or fuel briquettes;

- Simple installation. To install the stove, it is enough to connect it to the pipes of the heating system.

When choosing a furnace with a water circuit, you should pay attention to the characteristics of the material of manufacture. The body must be made of steel with a thickness of 2 mm or more. In a heat exchanger for long-term operation, the manufacturer must use heat-resistant sheet steel with a thickness of 3 mm or more.

Many summer residents use ash (a product of fuel combustion) to fertilize their backyards. Therefore, fuel briquettes are especially popular. They are not only economical, but their ash also contains a large amount of mineral components.

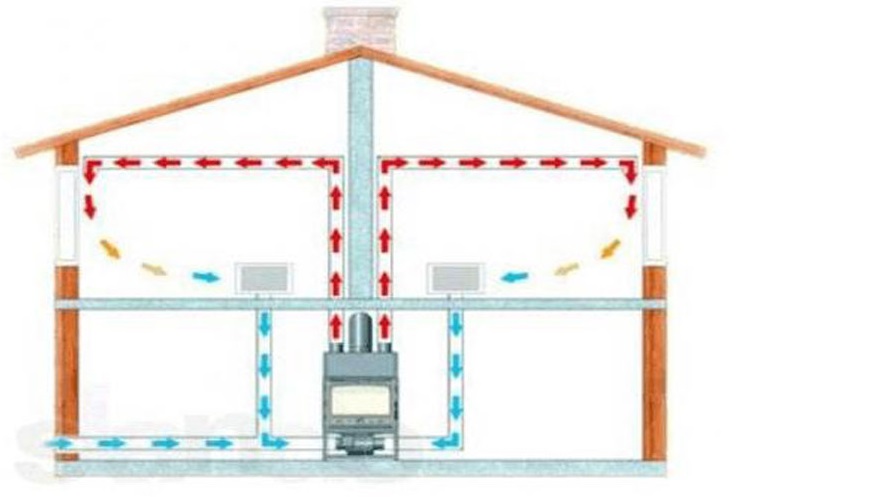

Air heating with a brick solid fuel stove

With the correct organization of air heating using a solid fuel stove, you can provide a stable thermal regime in a house with a small and medium area. One of the best options in this case may be brick solid-fuel air heating stoves.

In this case, the air is heated through the walls of the structure and through a complex system of chimneys - rough. Therefore, all brick solid fuel stoves for air heating have impressive dimensions. It is important to choose the right masonry scheme, since it is necessary to observe the proportions of honey in the combustion chamber and other structural elements. In the event of an error, the efficiency of the furnace will be low, which will not ensure the proper level of air heating in the house.

The important stages of arranging air heating using a brick oven are:

- Installation of a separate foundation... The total mass of the structure is high - an ordinary brick screed will not withstand it. Therefore, before laying the stove, they equip a separate foundation, which should not be associated with the brownie;

- Chimney. Traditionally, a chimney is made for a brick oven from the same material. However, due to its square section, it does not have high thrust rates. Therefore, it is recommended to install modern sandwich chimneys made of heat-resistant galvanized steel and a layer of insulation made of basalt wool;

- The device is rough... This is a system of smoke ducts located in the inner wall of the house. Passing through them, the heated air additionally heats not only the room where the stove is installed, but also the rooms adjacent to it.

It is important to choose the correct cladding material for a solid fuel air heating furnace. Artificial stone or ceramic tiles can be used along with traditional sand-lime bricks. They must have a sufficiently high heat capacity so that after the final combustion of the fuel, the air in the room can still be heated from the walls of the furnace for some time.

Additionally, a water heat exchanger can be installed in the combustion chamber of a brick oven to connect it to the heating system. This is done even at the stage of erection of the structure, since the modernization of an already folded furnace is laborious.

Reviews of solid fuel heating

One of the ways to create an objective opinion about this type of heat supply is to read the reviews in detail. They can be both positive and negative. It all depends on the correct choice of the type of heating, its installation and further operation. Consider the most common reviews of solid fuel heating boilers:

- We decided to replace the old small brick oven with a new steel one at the dacha. After a long period of choice, they settled on a model with a heat exchanger. We hope to make water heating in the future, since the air did not warm up evenly from the old stove, dampness appeared in the whole house;

- Our neighbors made themselves a brick oven. First impressions are great and consumes a lot of firewood. However, having familiarized ourselves more closely, we realized that this is exactly what we need. We have a small house (60 m²) with two rooms and a kitchen. We don't want to put the boiler on, so we decided to order the services of a stove-maker. We hope that the oven will last a long time.

The advantage of solid fuel heating is a relatively quick upgrade for a different type of fuel. Almost all boiler models are designed for the installation of a gas or diesel burner. Therefore, if you plan to supply the gas main to the house, you can safely purchase a solid fuel boiler in which you can install a burner.

In the video, you can see an example of self-manufacturing a solid fuel boiler: