The main problem of the heating system of a large house is the rapid cooling of the coolant. This is typical for classic one-pipe and two-pipe systems. Their alternative is a properly designed do-it-yourself collector heating system for a house: circuits, nodes, groups.

Installing a collector heating system

First, you need to decide - do you need a collector water heating system? It is used only in cases where the cooling rate of the coolant in the pipes in the classical scheme will be critical or in large houses. The main difference is the division of the system into several heating circuits that operate independently of each other.

Despite the positive aspects, making the right collector heating with your own hands will be problematic. Therefore, before choosing a certain scheme (or drawing it up), you need to take into account several important factors of the relevance of the installation:

- Large area of the house... For uniform heat distribution, several heating circuits need to be made;

- Ineffective installation of the tee circuit... It can influence the hydraulic distribution in the entire heating system;

- The need to disconnect individual rooms from heating... This is one way to optimize energy costs.

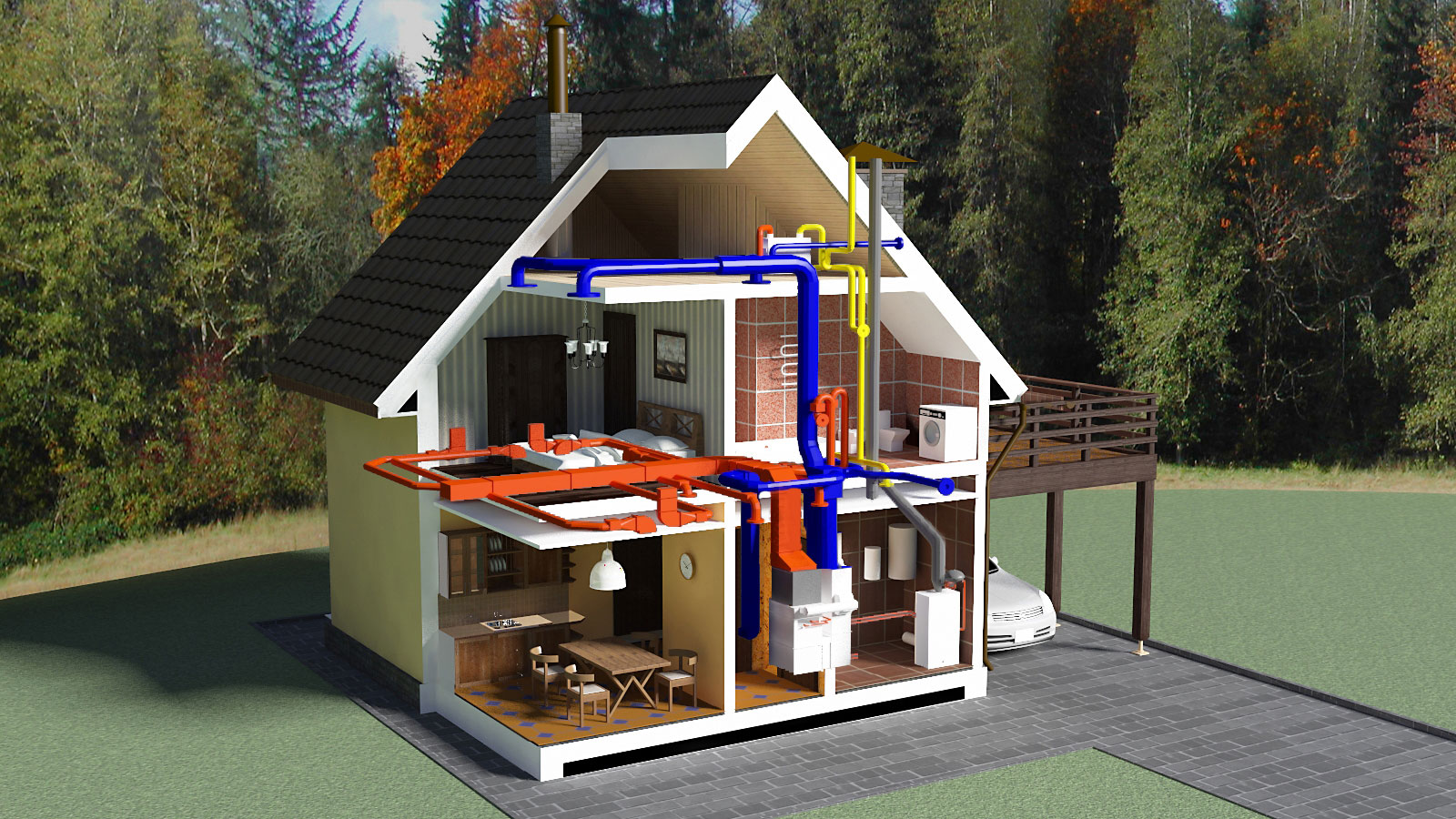

Considering these factors, collector heating of a two-story house is the most optimal way to organize autonomous heat supply.

If, when calculating the standard scheme, the difference between the temperatures in the supply and return pipes is more than 25 ° C, this is the first sign of the need to install distribution heating in a private house.

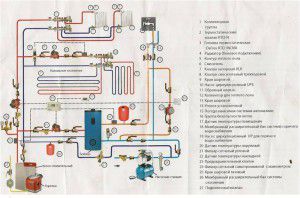

Composition of the collector heating system

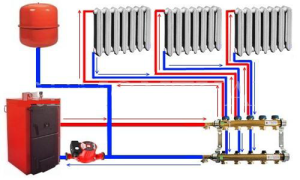

At the first stage, it is necessary to familiarize yourself with the principle of designing an autonomous heat supply. The simplest scheme of collector heating consists of one distribution unit, to which individual lines of the system are connected.

The set includes standard components - a boiler, a circulation pump, an expansion tank and a safety group. The manifold assembly is installed directly next to the boiler and consists of two elements:

- Input... It is connected to the supply pipe from the heating device and distributes the hot coolant along the circuits;

- Output... Return pipes from separate highways lead to it. It is necessary to collect cooled water and send it to the boiler for further heating.

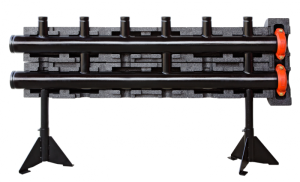

Complex collector groups for heating are equipped with devices for regulating the volume of the coolant supply - thermal heads (inlet) and mechanical stops at the outlet.

It is best to purchase factory-made collectors. Since they are designed for certain heating parameters.

This principle is used to organize heat supply for a one-story private house, where the power of the circulation pump will be sufficient to ensure normal pressure in the pipes. For a two-storey building, two collector groups for heating can be installed.One of them will be intended for distribution along separate circuits, and the second serves as the main component of a warm water floor.

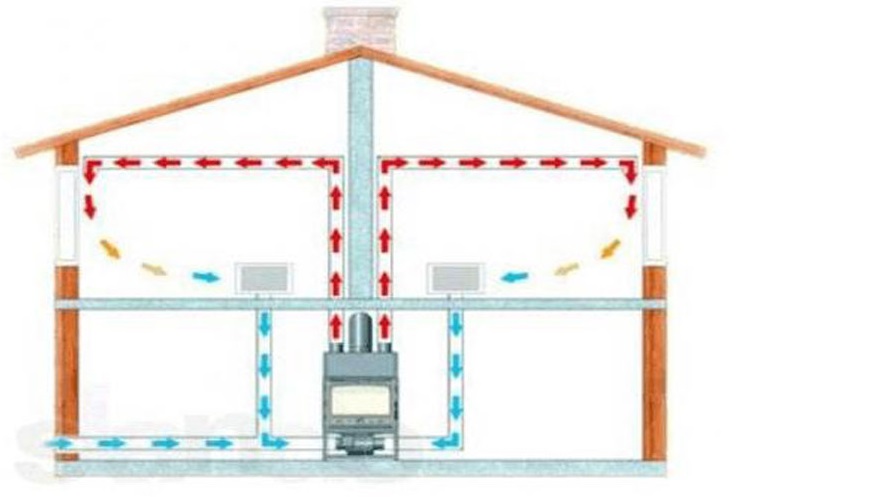

For such a scheme, it is necessary to calculate the parameters of each circuit. Most often, it becomes necessary to install the following additional components:

- Circulation pumps for each circuit;

- Mixing unit. It is necessary to regulate the temperature of the coolant in the collector. The channel connects the direct and return pipes and, with the help of a regulating device (two or three-way valve), flows with different degrees of heating are mixed.

The traditional scheme of collector heating of a two-story house includes distribution nodes on the first and second levels. But it all depends on the total area of the premises and, as a result, on the length of individual highways.

You also need to take into account heat transfer and optimal thermal conditions in each room.

All collectors located in living quarters must be installed in special closed boxes.

Diy collector heating at home

Is it difficult to make and install a heating system of this type with your own hands? It should be remembered that it is much more complicated than a one-pipe or two-pipe. The main difficulty lies in the exact calculations of each manifold unit for heating.

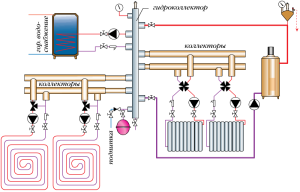

If the heating of the collector type is intended for a house with a large area and many separate highways, it is recommended to install a distribution manifold with a hydraulic compensator function. It differs from the standard ones in the connection of the supply and return collectors with the help of branch pipes. Its installation provides the following advantages:

- Prevents the occurrence of water hammer;

- Compensates for pressure differences due to thermal expansion of the coolant in the supply pipe;

- Automatic mixing of water streams and, as a result, reducing energy costs.

A comb of this type is installed in the collector system of hot water heating after the safety group. It should be located next to the boiler. If there are additional distribution nodes in the system, they should not be communicating. Their design is similar to that for underfloor heating in collector heating in a private house.

Often, it is on them that groups for automatic regulation of the coolant inflow are installed. In complex collector heating schemes, the central comb is equipped only with circulation pumps and shut-off valves for each circuit.

The installation of additional distribution units is necessary in order for each circuit to have approximately equal length.

Calculation of collector heating

When performing a preliminary calculation of the parameters of collector heating, made by hand, you need to take into account the throughput of the pipe from the boiler and the total volume of the coolant. It is important that the amount of water leaving the boiler heat exchanger is equal to the incoming one. Thus, it is possible to achieve an even heat distribution in the collector heating of a two-story house.

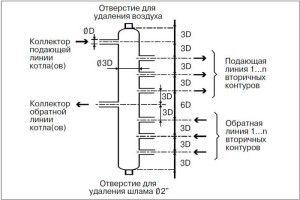

It is also important to maintain the hydraulic balance of the system. In practice, it is recommended to use special software packages to perform the calculation. But for small collector groups for heating, you can calculate the geometric dimensions of the comb yourself. To do this, you should be guided by two basic rules:

- The diameter of the inlet pipe of the collector must be equal to the sum of the cross-sections of the supply pipes for each circuit;

- In a single-body manifold, the distance between the inlet and outlet groups should be 6 pipe diameters. In this case, the cross section of the comb body is equal to 3D.

This is the general design principle for collector-type heating.It can vary depending on the individual characteristics of the system.

The power of the circulation pumps for each heating circuit is calculated individually, depending on the length and amount of heat carrier in them.

Heating manifold manufacturing

For greater reliability, the main distribution manifold in a collector water-type heating system should be made of metal. For this, you can use pipes of both square and round cross-section. The former are preferable, since the installation of the branch pipes in them is much easier.

To do this, you will need the following tools and materials:

- Pipe for the main heat of the heating manifold. Its dimensions must correspond to the calculated ones;

- Branch pipes for the distribution of the coolant along the circuits. They are made of round pipes with a diameter of 16 to 25 mm, depending on the parameters of the system;

- Shut-off valves - ball valves for each circuit;

- Tools: welding machine, angle grinder (grinder), tape measure, level.

First, the main body of the comb is made by hand for collector heating. On its surface, with the help of a welding machine, through holes are made into which the branch pipes will be installed. Then they are welded, and the tightness of the entire system is checked. To do this, you need to simulate the operation of the system. The outlet pipes are sealed, and the water supply is connected to the inlet of the future collector heating of a private house. With the help of pressure gauges, the operating mode of the system is established and the absence of leaks in the structure is visually checked. The next stage - the pressure is gradually increased to the maximum design. Only after carrying out such tests can the collector groups be installed in the heating system.

It is best to use pipes with a wall thickness of 1 mm or more. For continuous operation, it is recommended to paint the collector surface with a special paint.

Ready-made designs of collector heating

The best option for organizing collector heating in a large two-story house is to purchase factory-made combs. They differ from self-made ones in greater reliability and accurate characteristics, which is important in any system.

However, one should take into account their high cost. It directly depends on the number of connected circuits, the diameters of the inlet pipes and the geometric dimensions of the collector.

| Model | Number of branch pipes | Design power, kW | price, rub. |

| ELTERM KP2 | 2 | 14 | 7260 |

| Meibes v2 | 2 | 20 | 12100 |

| Meibes v3 | 3 | 25 | 22800 |

Installing these components in a collector-type heating circuit of a two-story house will help optimize the operation of the entire system. Along with this, possible heat losses must be taken into account, since the comb has a relatively large area. To minimize them, it is recommended to insulate its surface with mineral wool.

In the video, you can familiarize yourself with the instructions for making a collector from polypropylene pipes: