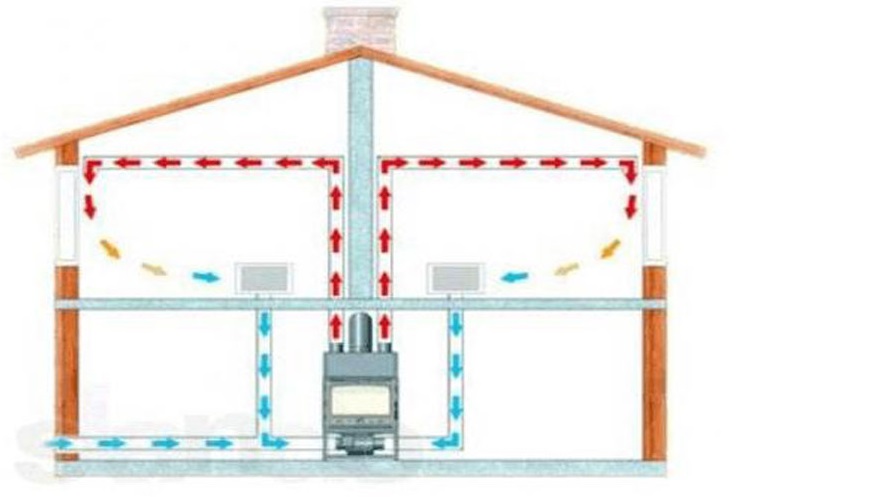

Frame buildings are considered one of the most popular today. They are economical, lightweight, construction technology is simple and understandable. However, to ensure an optimal microclimate inside the building, the walls do not have enough thickness.

External insulation will allow to increase heat protection, in addition, competent thermal insulation of the house, in addition to comfortable living, increases the service life of the building. How to insulate a frame house from the outside? What is needed for facade cladding, which technology to choose?

Varieties of materials and tools

- Cellulose insulation is ecowool, which does not burn, does not rot, insects and rodents do not start in it. It has high sound and heat insulation performance, while being environmentally friendly. For laying ecowool you will need special equipment; it is almost impossible to carry out external insulation with it with your own hands. This is not the most economical option for improving the characteristics of a frame building, however, one of the most reliable, easy to install.

- Hemp or linen hemp mats are ideal for frame buildings. Their capillary structure is similar to wood. Good moisture absorption. When insulating a frame building externally with linen or hemp mats, no vapor barrier is needed. Instead, it is sufficient to use a vapor permeable membrane.

- Straw, sawdust with good sound and heat absorbing properties, environmental friendliness, durability, affordable.

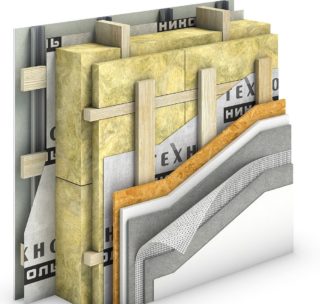

- Mineral wool, non-flammable, vapor-proof material. It is more expensive than polystyrene, but attracts with a long service life, is easy to use. The only drawback is hygroscopicity, which will require additional vapor barrier equipment.

- Polyfoam, expanded polystyrene is a popular option for insulation. The installation method is simple, affordable, the boards have good moisture and air tightness.

- To insulate a frame house, you can also use peat, an environmentally friendly non-combustible material that is resistant to decay with high moisture-absorbing characteristics.

You will need tools:

- Electric drill, hacksaw, screwdriver;

- Level, construction knife, several spatulas, including those with a serrated edge;

- Hammer, building level, glue;

- Reinforced mesh with a cell of 50 mm, dowels with an umbrella or mushroom head, screws, nails;

- Wooden lathing bars with a width equal to the width of the selected material.

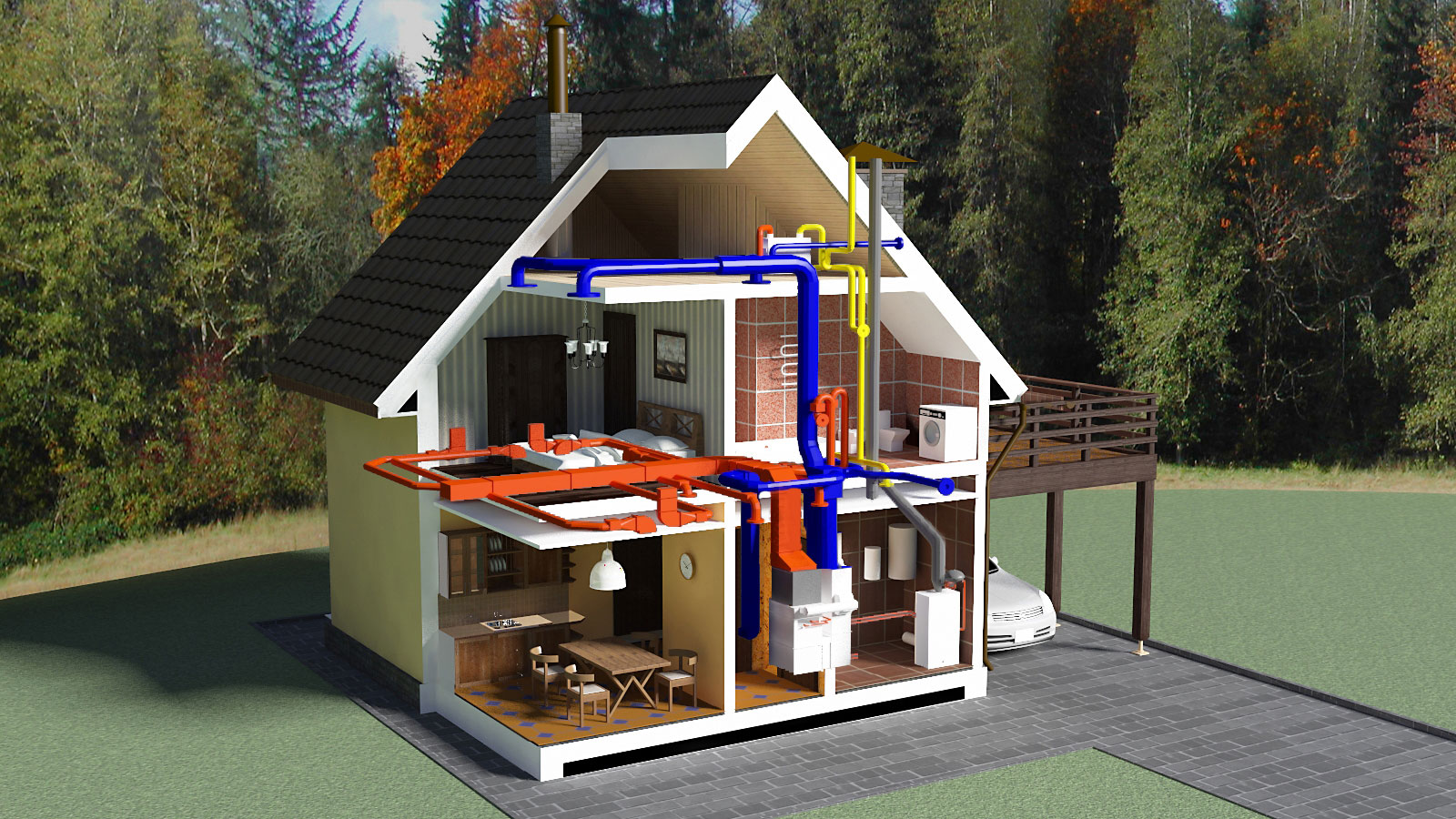

Warming procedure

- External surface preparation.

- Arrangement of a vapor barrier.

- Insulation installation.

- Finishing work.

The first stage of the work on the cladding of the frame building from the outside is preparatory. The surface of the walls, supporting structures are cleaned of dirt, dust, removing wire, nails, adhering particles. If the surface of the facade is uneven, there are cracks, it is worth first leveling it using the plastering method.

This will ensure the maximum tightness of the contact between the thermal insulation and the outer plane of the walls. For better adhesion, the surface is primed, while the consumption of primer per 1 m 2 is 150 ml. After the soil dries out, they begin to install the insulation.

Technology

Ecowool... In addition to excellent performance characteristics, it is good in that it forms an even, seamless web when laid. The easiest way in this case is to install insulation between the posts with additional wind protection, for example, from hydrophobized plates. The process looks like this. First, the crate is installed, while the structure from the inside should be closed with kraft paper, reinforced with polyurethane foam. After that, holes are made in the canvas, a hose is inserted and ecowool is blown out, controlling the density of the blowing. The surface on the outside must be flat, so the irregularities are cut with a construction knife. Usually ecowool dries up in 2-3 days, after which finishing is started.

Useful Tips

For arranging thermal insulation, it is better to use not rolled, but plate materials.

To eliminate the appearance of cold bridges, installation of layer-by-layer installation of insulation with an overlap of 50 mm wide will help.

Thermal insulation materials are selected based on the climatic zone. The optimal insulation thickness is 100-250 mm, the minimum is 30 mm.

If it is decided to use sawdust, straw, they are first allowed to soak for 2 months. If it is necessary to speed up the process, the raw materials can be moistened with liquid glass.

If sawdust, straw are used, metal pipes with walls of at least 3 mm are mounted in the layer during insulation. In this case, you do not have to arrange a vapor barrier, the excess moisture will be completely absorbed by a mixture of sawdust and cement.

When installing linen or hemp mats, the frame racks are installed at a distance from each other, the step should be 2-3 cm wider than the insulation.

Most of the technologies for insulating frame buildings are simple and straightforward. But if there are doubts that it will be possible to do everything exactly according to the technology, it is worth using the services of the masters, paying for the work.