The constant rise in the cost of energy has led to the emergence of new heating technologies. In addition to modernizing existing systems, manufacturers offer fundamentally new methods of heating water. Of particular interest is the do-it-yourself induction heating of a private house with a boiler.

Features of induction heating

To increase the temperature of the coolant, it is necessary to ensure the transfer of heat from the energy carrier to the water. In traditional electric boilers, heating elements are responsible for this. However, they have a number of disadvantages, which are primarily associated with increased electricity consumption. A modern induction heating furnace works on a different principle.

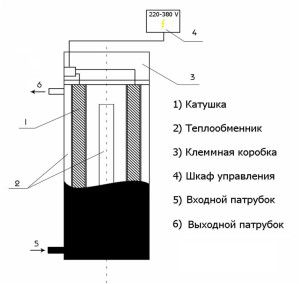

In order to make induction heating with your own hands, you need to thoroughly study the specifics of its work. Its functioning is based on the principle of an electromagnetic inductor. Its design consists of two windings, each of which performs a specific function:

- Primary... It is necessary to convert the electricity supplied to it into an eddy current. This is one of the steps to create an induction phenomenon;

- Secondary... Due to the influence of the electromagnetic field, it begins to heat up, thereby transferring the received thermal energy to the coolant.

In practice, for the manufacture of induction heating of a private house with your own hands, you will need an external circuit that performs the function of a body. The inner core is made from a steel rod, which is usually 10 mm thick. This design allows for a reduction in weight while at the same time improving work efficiency. For factory models, the efficiency rate can reach 98%. At the same time, even a properly made induction heating boiler with your own hands has a value of this characteristic of the order of 87-90%.

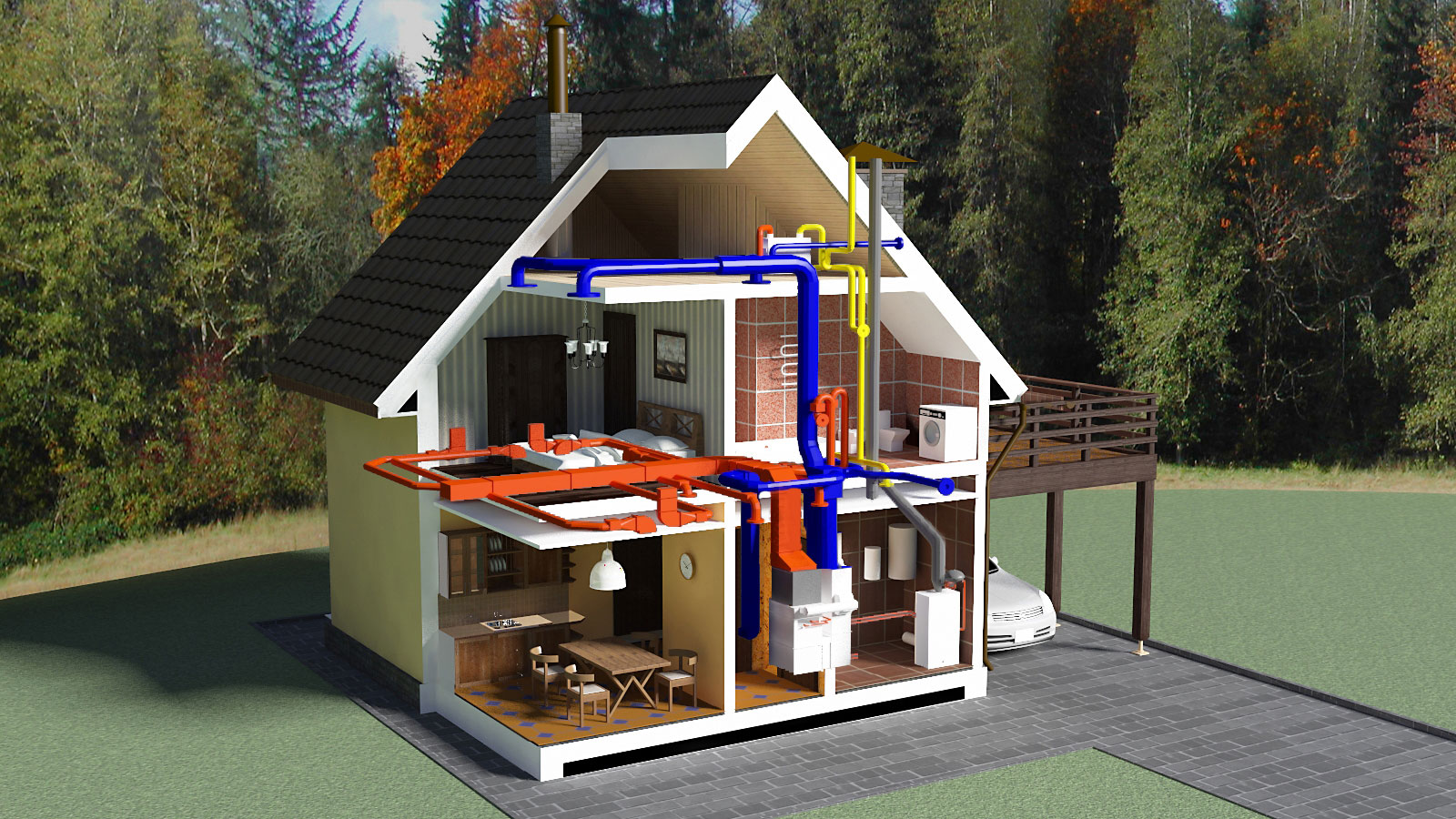

All induction heating systems are not equipped with circulation pumps, expansion tank and security system. These components must be purchased separately.

Pros and cons of induction boilers

Is this type of heating really as efficient as advertised by manufacturers? Reading reviews about induction heating, it is impossible to draw an unambiguous conclusion. Many consumers complain about the high consumption of electricity, some home-made models of boilers are clearly dangerous to operate.

Before making an induction heating boiler with your own hands, select components and components for it - it is recommended to familiarize yourself in detail with the pros and cons of this type of heat supply.

Benefits:

- Rapid increase in the temperature of the coolant to the required level. Unlike the operation of heating elements, induction heating of water for heating does not require additional insulating materials. Those. thermal energy from the rod is transferred directly to the coolant;

- Long service life. This is due to the absence of moving parts and the high reliability of materials of manufacture;

- Small dimensions of the structure;

- Scale does not form on the inner walls. This is due to the slight vibration of the rod during its operation.However, if you read reviews about induction heating boilers, then no one complains about the high noise level.

But along with this, it is necessary to take into account the negative aspects of the operation of heating boilers of this type:

- High cost of factory models. Truly high-quality electric induction heating boilers are made using modern materials, the cost of which, to a greater extent, determines the high price. Therefore, home-made models are significantly inferior in quality and technical parameters to the factory ones;

- To install boilers with a capacity of more than 7 kW, it will be necessary to equip a 380 V power grid. Otherwise, the load will not allow the equipment to work in normal mode;

- In the absence of water during the operation of the induction heating furnace, overheating and failure will occur. Therefore, the design must include pressure sensors that are connected to the circuit breaker. If the pressure drops, the device will automatically shut off.

Having decided that you still need to do induction heating yourself, you can start choosing the optimal boiler scheme and calculating its parameters.

The induction heating principle has been used for decades in the steel industry to heat metal. It is from this industry that induction heating boilers came from.

Homemade induction boiler

To make induction heating of a private house with your own hands, you first need to make a case. For this, heat-resistant steel should be used. As the inner core, a steel pipe is usually used, on which a copper wire winding is installed.

To reduce heat losses, the outer walls are insulated with basalt wool. Thus, it is possible to install induction boilers for heating a private house in utility rooms.

After installing the inner loop, the following work must be done:

- Lead the contact wires through the special holes on the external structure.

- Insulate the cables carefully in the area where they pass through the outer casing.

- Connect the boiler to the control system. It is best to purchase a factory model of this component, as it includes protective and regulating elements.

Before the first start-up of a self-made induction heating boiler, you need to check the tightness of the entire structure. To do this, one of the nozzles should be sealed, and water should be supplied to the second using a pump. After filling the internal space, increase the pressure to the maximum design. Usually this figure is 15-20 atm.

In practice, truly reliable and efficient boilers for induction heating of water in heating cannot be made independently. The only exceptions are small structures that rather perform the function of hot water supply than heating.

This is due to the complexity of compliance with all technological manufacturing standards. Often, in reviews of homemade induction heating boilers, you can encounter attempts to make them yourself. But after a series of tests, the choice is stopped on the factory models of this heating equipment.

In the event of an improperly made winding, an inter-turn electrical breakdown may occur. This will short-circuit and damage the equipment. Therefore, boilers must be equipped with an RCD.

Induction heating organization rules

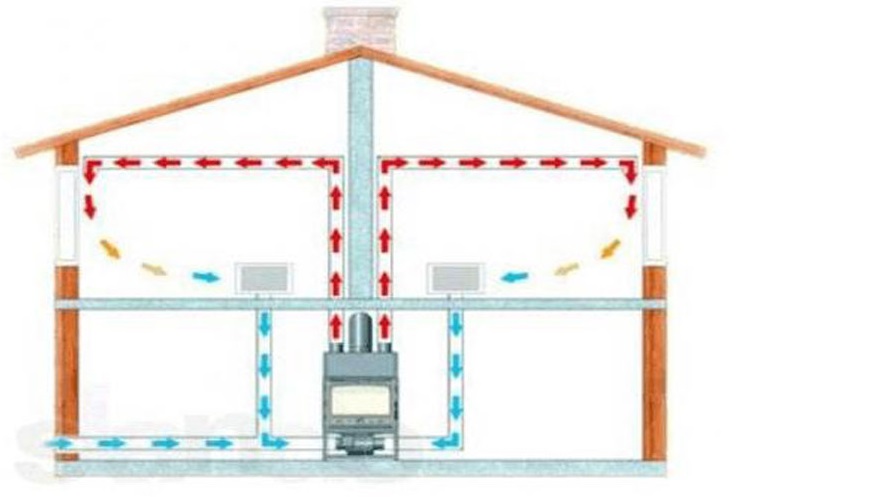

Since induction electric boilers for heating differ from ordinary ones, the requirements for their operation are also different. First of all, you need to know that the installation of this type of equipment is possible only in closed heat supply systems. To improve the circulation of the coolant, a pump can be installed.

In order for heating from an induction hob to be safe, it is necessary to adapt the existing wiring. To do this, calculate the power of electrical appliances in the house, including the boiler, and add a margin of 20% to the resulting figure. The technical characteristics of the electrical cable must not be less than the received figure.

The connection of the induction heating furnace to the mains must be done through a separate cable. It must be connected directly to the central distribution board. The connection of other devices to this power line is prohibited.

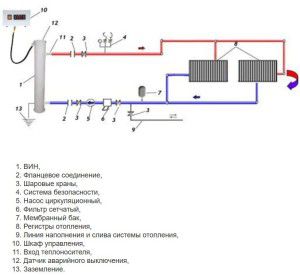

To improve the efficiency and safety of DIY induction heating, you will need to install the following components:

- Expansion tank... It is necessary to compensate for pressure in case of its excess due to overheating of the coolant. The temperature inside an induction boiler for heating a house can reach + 110 ° C;

- Pressure and temperature sensor... They are connected to the central control unit;

- Circulation pump... Its installation is optional, but desirable. The natural thermal expansion of water may not be enough to create a normal speed of movement;

- Security group - air vent and water drain valve.

Often in reviews about induction heating, you can find complaints about the deformation of plastic pipes due to excessive overheating of the water. To avoid this, all technical and operational characteristics of the heating system must comply with the preliminary design.

It is recommended to install an emergency generator in order to avoid water cooling in the event of a power outage. This is especially true for induction heating systems in a private house.

Induction boiler manufacturers overview

But what if you need induction electric boilers for factory-made heating? Alas, at present there are not many manufacturers on the market whose products meet international standards.

When completing a do-it-yourself induction heating, it is recommended to analyze the current offers on the market. In this case, it is necessary not only to familiarize yourself with the reviews of induction heating boilers, but also to check their compliance with current standards. It will not be easy to do the latter, since at present there are no GOSTs and SNiPOs regulating the production process of their manufacture. The most you can check is with the manufacturer's internal specifications.

But how, in this case, to equip induction heating of a private house with reliable equipment? To address this issue, we offer an overview of manufacturers of boilers for induction heating systems.

Geyser

One of the largest and most reliable companies in the production of equipment for electrical heating. Currently, the consumer can choose an induction heating boiler with a capacity of 4.5 to 250 kW. It is noteworthy that the structure has a class of electrical safety "2", which does not require the organization of an additional ground loop.

Models of the "E" series have a storage tank, which makes induction heating of the coolant for heating more economical.

Edison

The company specializes in the production of large heating systems for heating public and industrial buildings. The supplied set of equipment includes all the necessary components. The range includes models designed for heating from a low power induction cooker. But their number is extremely small.

Miratron

A feature of induction-type electric heating boilers from this company is a modular layout. This makes it possible to increase the capacity of the heat supply system at any time without completely replacing the equipment. The range includes boilers from 4.5 to 30 kW.

Before purchasing an electric boiler for induction heating, it is recommended that you familiarize yourself with its technical data sheet. It should indicate the operating conditions of the equipment.

Induction heating reviews

To form an objective point of view about the relevance of purchasing this type of equipment, you need to read the reviews about boilers for induction heating:

- They decided to install a new induction boiler to heat the summer cottage. According to the manufacturer's assurances, he must heat the water in a very short time. However, in fact, it took about 2 weeks to return to normal operation. During this time, it was necessary to replace the control unit under warranty;

- We have heating in our house from a solid fuel boiler. In winter, the water in the pipes heats up for a very long time. Therefore, we decided to install an additional induction, operating from the mains. Now we first start it, and then wait until the main boiler reaches the desired temperature. This system is very convenient;

- I wanted to assemble an induction boiler myself. But after several unsuccessful attempts, I decided to purchase a factory one. It's good that I calculated everything before - power, pump parameters. Once installed, the heating runs like clockwork. Very satisfied.

Is it worth installing an induction boiler for autonomous heating? This option will only be acceptable if the house does not have a gas connection. Only then can the options for installing induction heating be considered.

In the video, you can familiarize yourself with the features of the organization of induction heat supply: